INSTALLATION INSTRUCTIONS

1. Pump Location

The John Blue Squeeze Tube Pump should always be mounted even with or lower than the

fertilizer tank for accurate metering. The pump can be mounted to any flat surface. There is no

need to have the pump mounted in the middle of the equipment. The pump creates enough

pressure to place it at the end of the implement. Make sure all connections, filters and

couplings are tight so the pump can lift and pull product to it. The speed should not exceed 100

RPM.

Any shaft that turns in ratio to the ground can be considered to drive the pump. The pump only

requires a small amount of torque to turn it. Typically it is one of the seed shafts, which can be

used, but try to have it before the transmission so that if you change seed population the

fertilizer rate remains unchanged.

2. Pump Mounting

Two angle iron bars with holes are supplied and can be bolted to each side of the pump. Undo

the frame end plate bolts, match up the holes in the angle iron and retighten the nuts. The

hook bolts supplied can be used over the angle iron or the frame channel to bolt the pump to

your equipment.

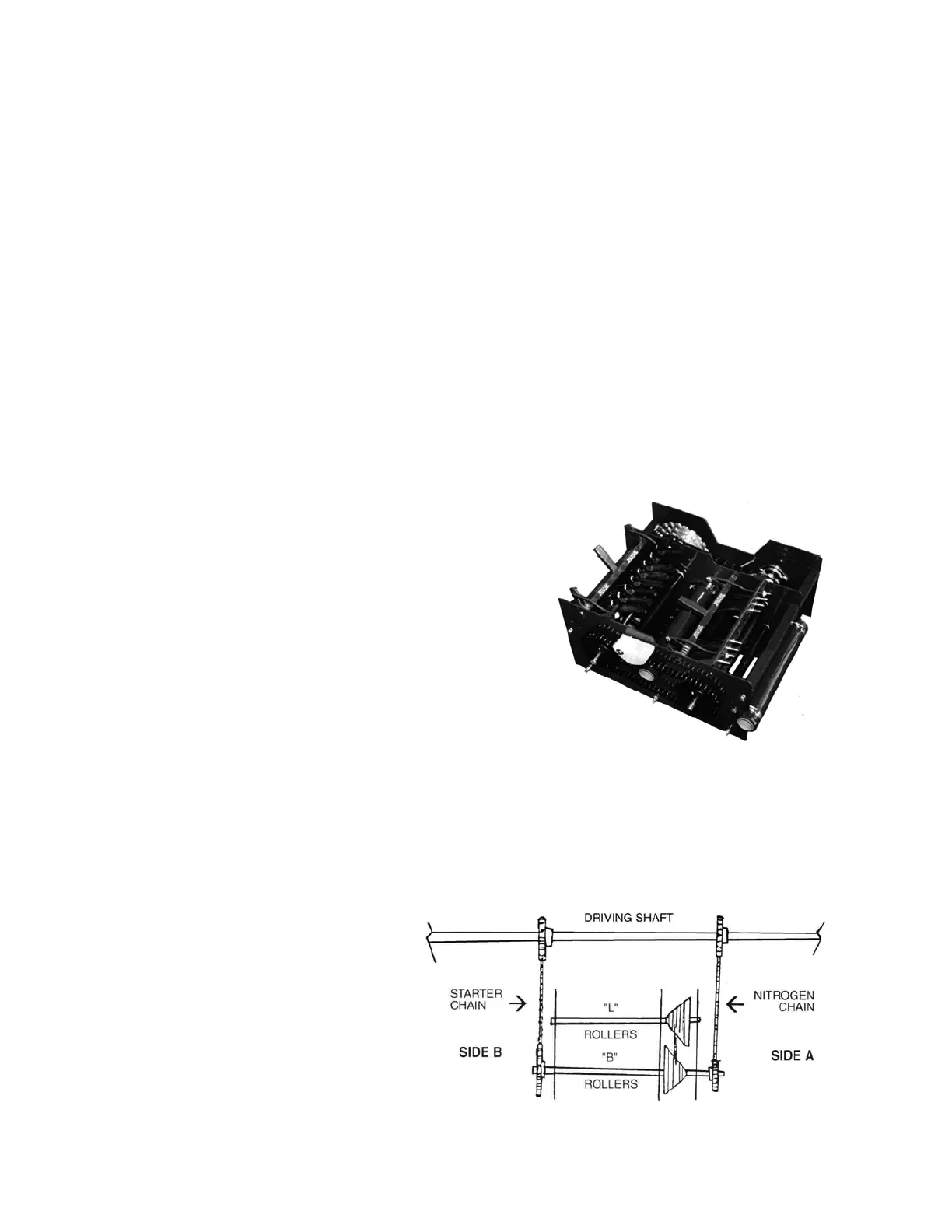

3. Pump Mounting of Combination Pumps

The mounting of combination and double pumps

is not different than what is described above as to

location and drive system. The exception is when

you want

to keep the starter fertilizer always at the same

rate and want to use the coned sprockets to

vary the nitrogen rates. Figure 1 shows this

type of system, where you drive both sides of

the pump.

(Picture A)

Special plumbing is needed because both manifolds will have product flowing to it. If two

different products are to be pumped, two independent plumbing systems must be used. As the

center manifold is fed through the chain it is important to check the clearance with the hose and

fittings used.

Note: The sprockets that come on

the side across from the coned

sprockets are not used and must

be removed.

(FIGURE 1)

Loading...

Loading...