Step 2 Finding Sprocket Ratio

The sprocket ratio is used to

determine the size sprocket needed

on the ground wheel and pump

jackshaft.

1681 =

RPM Main Shaft x Wheel Diameter Ratio Pump Jackshaft to

Ground Wheel

Example: RPM is 23 (from step 1) and your wheel diameter is 30 inches.

Correct answer: 1681 = 2.4: Divide 1681 by 23 then divide the answer 73 by 30 = 2.4

(23)(30)

Step 3 Finding Actual Sprockets to Use

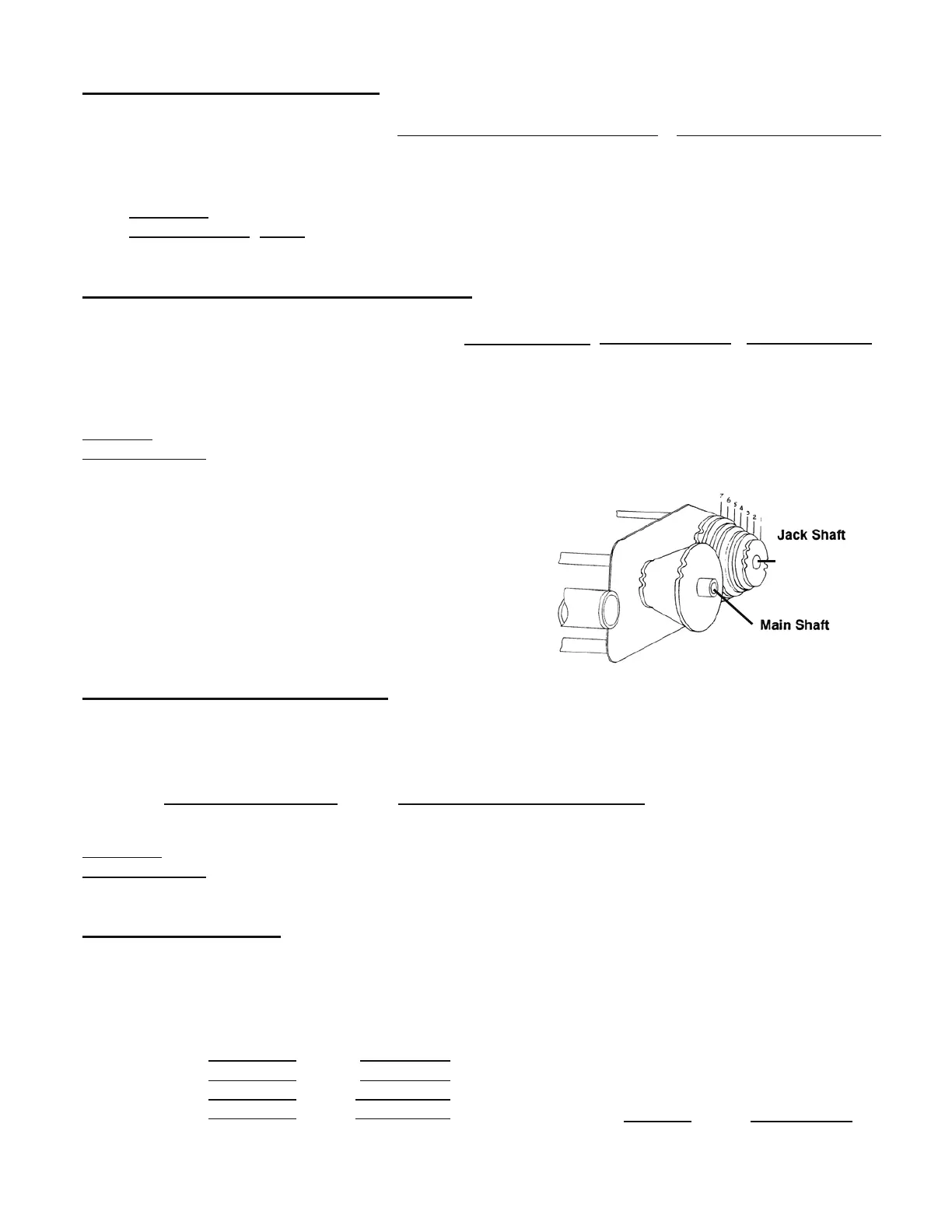

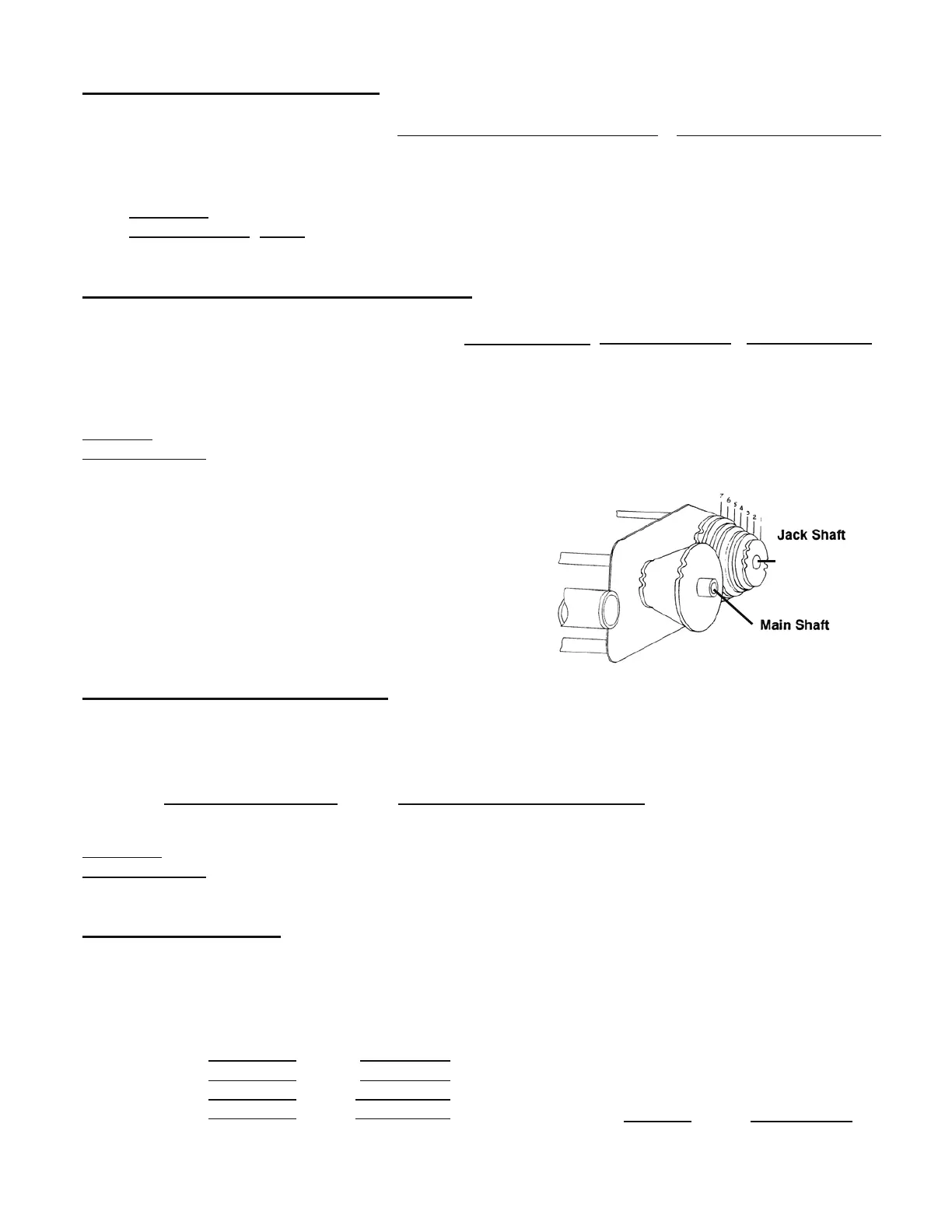

Count the number of teeth on the

driving sprocket you are using. The driving

x =

sprocket is the sprocket on the ground

wheel, rub wheel or existing shaft.

Ratio from Step 2 Teeth on Driving Teeth on Jack

Sprocket Shaft Sprocket

Example: The number of teeth on your driving sprocket is 10.

Correct Answer: 2.4 x 10 = 24 tooth sprocket on pump’s jackshaft.

Note that you may also use the coned sprockets to adjust the sprocket ratio between the

Jack (input) shaft and Main shaft according to this chart:

Main shaft speed vs. Jack

Direct Couple to Existing Shaft

When you want to turn the pump’s jackshaft directly from an existing shaft, complete Step 1 to

find the main shaft RPM for the desired GPA. At the desired speed of application count the RPM of

the existing shaft and divide that number by the mainshaft RPM to find the sprocket ratio.

RPM of Existing Shaft =

Mainshaft RPM from Step 1 Ratio Jackshaft to Existing Shaft

Example: RPM from Step 1 is 40 and your shaft turns 80 RPM’s at 5 MPH.

Correct Answer: 80 divided by 40 = 2.0 This is the ratio between the pump’s jackshaftand your

driving shaft. Use this factor in Step 3 above to select the correct cone sprocket position.

Adjusting for Speed

All calculations are based on 5 MPH. You need to adjust for the speed you plan to travel for

hydraulic driven pumps to get the right RPM. For ground driven pumps we need to insure that the

pump operates fewer than 100 RPM’s at the speed you travel. Take the RPM from Step 1 or if you

use the coned sprockets the adjusted RPM and multiply as follows:

Loading...

Loading...