Installation, Operation & Maintenance Instructions

3

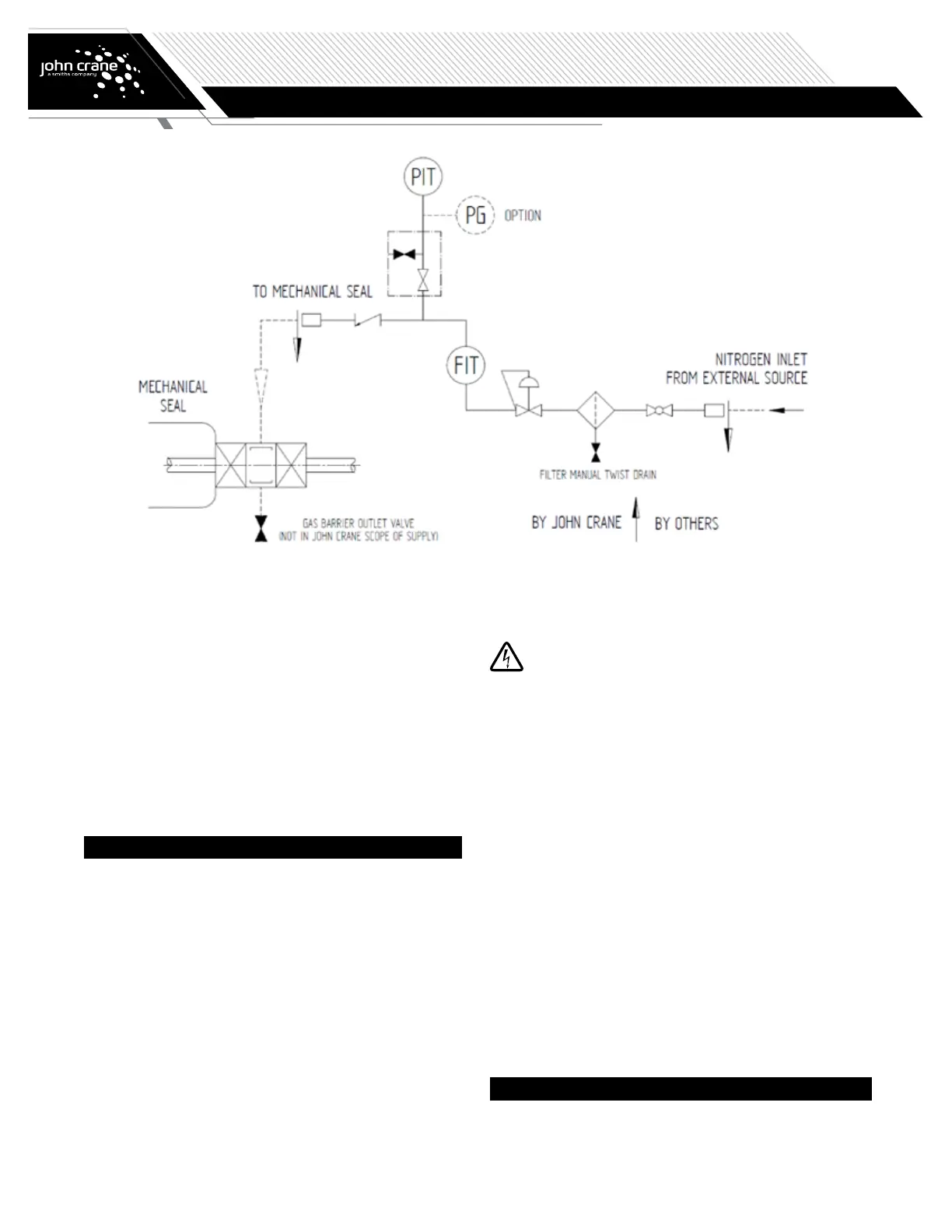

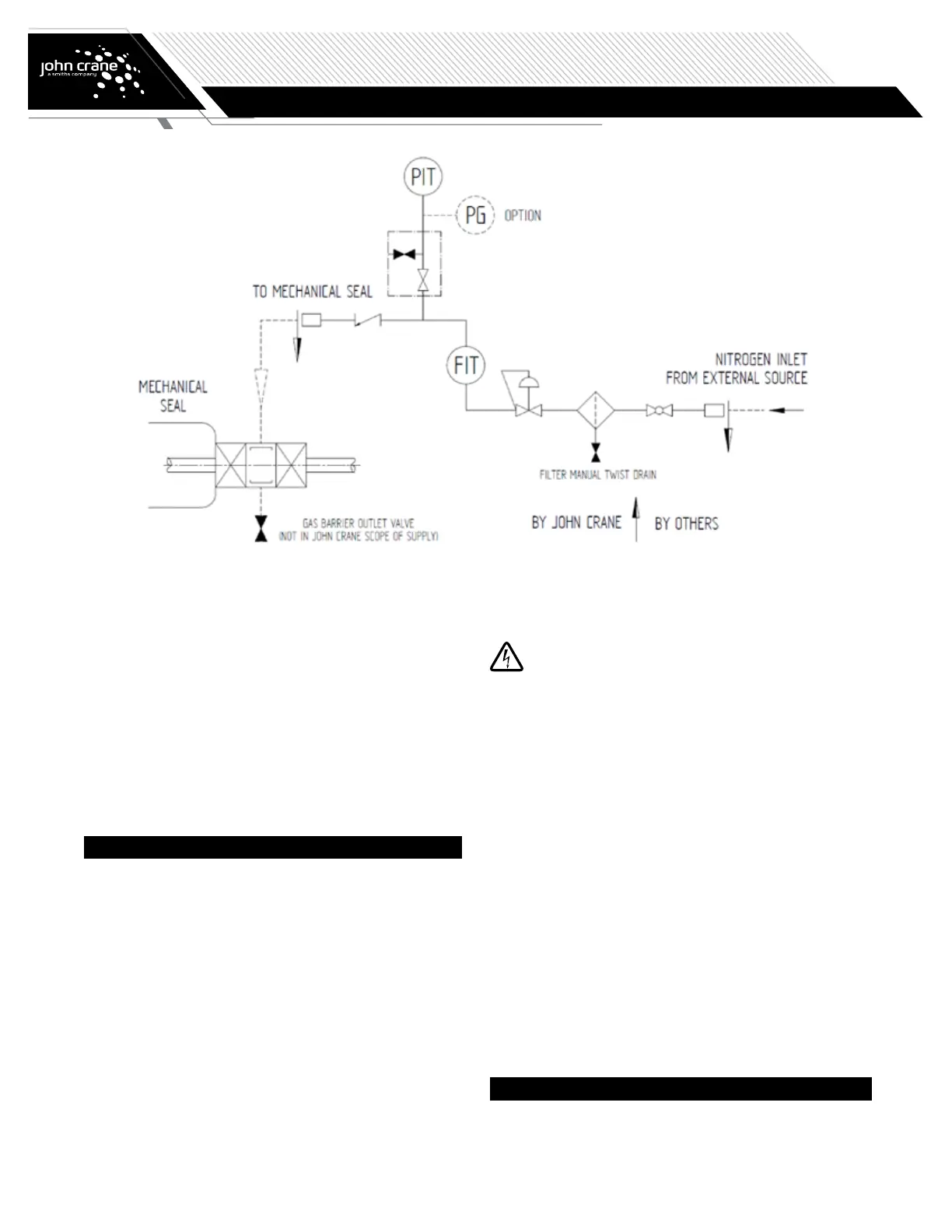

API PLAN 74

SEAL SYSTEMS

4.2 Instrumentation and fittings

The system is usually supplied with the following:

•

Barrier gas supply inlet (flanged or threaded)

•

Panel outlet to seal (flanged or threaded)

•

Pressure indicating transmitter (PIT)

•

Flow indicating transmitter (FIT)

And, upon request with the following options:

•

Pressure gauge (PG)

•

Pressure switch (PS) instead of a PIT

•

Flow indicator (FI) instead of FIT

•

Flow switch (FS) with the flow indicator

5. Installation and Assembly

5.1 Before installation

Prior to installation ensure that internally all connecting pipe work

has been thoroughly cleaned. Remove protection caps from pipes and

connections. Check all fittings/connections for damage replacing if

necessary.

5.2 Control panel mounting

Refer to the appropriate arrangement drawing for mounting details.

It is recommended that piping between the Plan 74 control panel and

the mechanical seal should be kept below 2 metres (72 inches) in length

wherever possible. If this length is exceeded, consideration should be

given to increased frictional losses and, if necessary, allowances must be

made when setting the seal pressure.

It is advisable to install a vent connection in the interconnecting

pipe work close to the seal chamber.

With the gas supply isolated, connect the barrier gas supply piping to

the inlet connection on the Plan 74 control panel and connect the panel

outlet connection to the mechanical seal gas barrier in (GBI) connection.

Do not open gas supply at this time.

5.3 Electrical connections

Only authorized and qualified personnel are permitted to

carry out work on electrical systems. International and

local safety regulations must be followed in all cases.

Before connecting cables, check the electrical data on the name plate

matches the available power supply and complies with the area hazard

classification.

Refer to the diagrams in the terminal housing and the supplier's

instruction manual for wiring instructions. Connect the electrical

component using flexible conduit or armoured cable to assist removal of

the component for maintenance purposes.

If passive switching elements are installed in potentially explosive areas

you should add suitable protective devices, following the pertinent rules.

5.4 Leak check

During transit, tube fittings may work loose, check all fittings/

connections for tightness. First checking that the barrier gas supply

pressure is within the limits of the Plan 74 control panel, slowly open

the barrier gas supply line isolation valve allowing the control panel to

pressurize.

Using a suitable leak testing liquid check all joints and if necessary,

rectify any leaks found.

6. Commissioning and Decommissioning

6.1 Commissioning

Before starting the machine (pump or mixer) carry out the following

operations:

Loading...

Loading...