10 A419 Series Electronic Temperature Controls with Display and NEMA 1 or NEMA 4X Watertight Enclosures

Product/Technical Bulletin

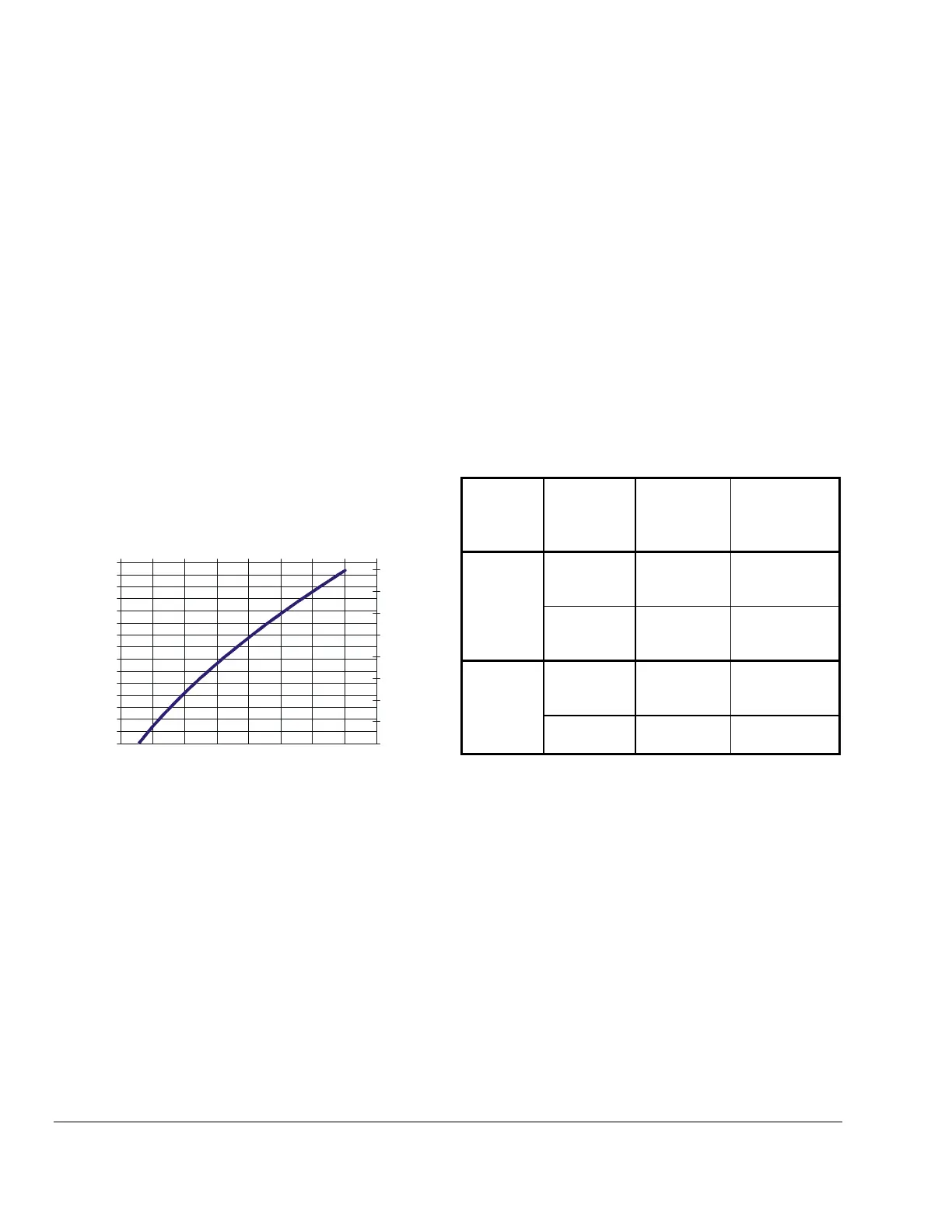

2. Check for proper sensor operation.

Disconnect all power sources to control.

a. Take a temperature reading at the sensor

location, using an accurate thermometer.

b. Disconnect the sensor from the control.

c. Use a reliable ohmmeter, to measure the

resistance across the two sensor leads while

the sensor is at the temperature taken in

Step b.

d. Refer to Figure 15 to verify that the measured

temperature and resistance conform to

established temperature and resistance

values.

e. If the measured values conform to the values

in Figure 15, proceed to Step 3.

f. If the sensor’s measured resistance value is

substantially different from the expected value

for that temperature, check the sensor wiring.

If sensor wiring is okay, replace the sensor.

-40

-20

0

20

40

60

80

100

120

140

160

180

200

220

240

260

500 700 900 1100 1300 1500 1700 1900 2100

Resistance in Ohms

Temperature

°F

-40

-20

0

20

40

60

80

100

120

Temperature

°C

Figure 15: Nominal Temperature vs.

Sensor Resistance

3. Check the A419 for proper operation.

a. Perform Troubleshooting Steps 1 and 2 before

performing this step.

b. Disconnect the load from the output relay

terminals.

c. Ensure that the Touchpad Lock jumper is

installed, so that the touchpad is unlocked.

d. Reconnect the sensor leads and supply power

to the control.

e. Replace the cover.

f. Check the control settings for proper values.

g. Press and hold the MENU button until Setpoint

appears (occurs in about 2 seconds).

h. Use the Up and Down buttons to change the

Setpoint temperature above and below the

current sensor temperature until the output

relay energizes and de-energizes as shown in

Table 4.

If the anti-short cycle delay has a time greater

than 0 minutes, the relay will not energize until

the timed delay has elapsed.

i. If the output relay does not perform as

indicated in Table 4, replace the A419 control.

j. If proper operation of the A419 control is

verified, reconnect the load and consult the

equipment manufacturer’s instructions for

troubleshooting the controlled equipment.

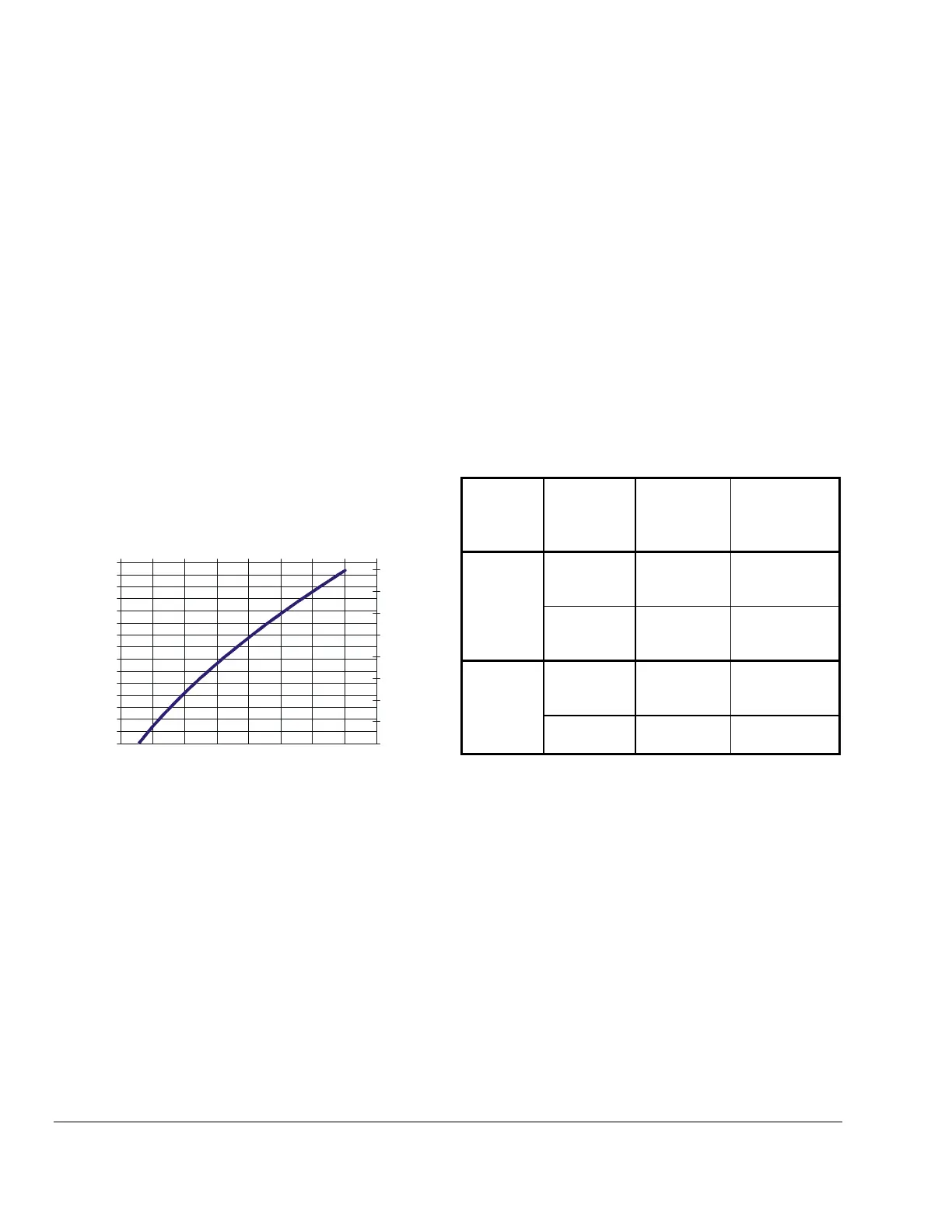

Table 4: A419 Output Relay Operation

Setpoint

Mode

Operating

Mode

Output

Relay

Energized

at…

Output Relay

De-energized

at…

Cooling

Setpoint

plus

differential

Setpoint

Cutout

Heating

Setpoint

minus

differential

Setpoint

Cooling Setpoint

Setpoint

minus

differential

Cut-in

Heating Setpoint

Setpoint plus

differential

Note: When the relay is energized, the N.O. contacts

are closed and the LED is illuminated.

Loading...

Loading...