VMA1400 Series Overview and Engineering Guidelines Technical Bulletin 4

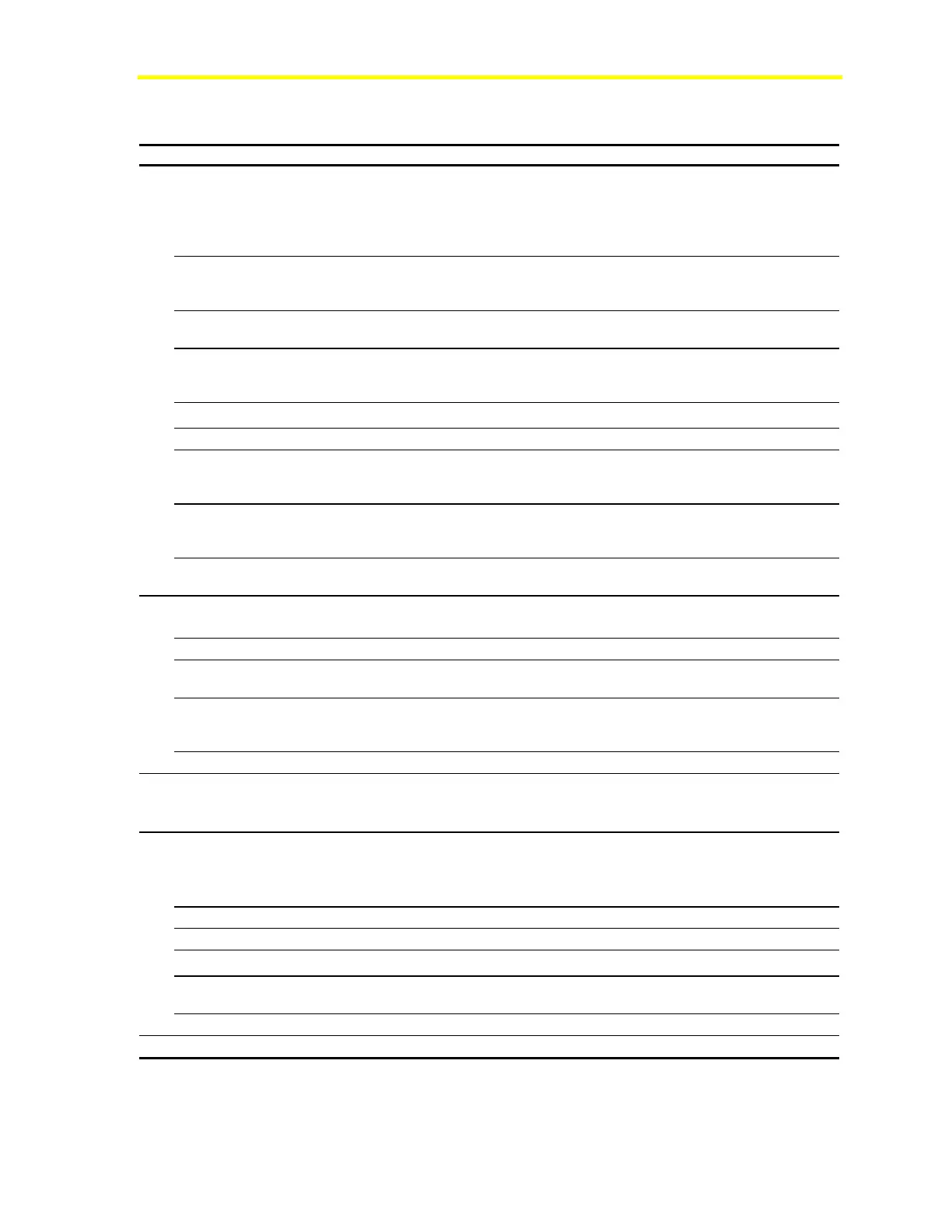

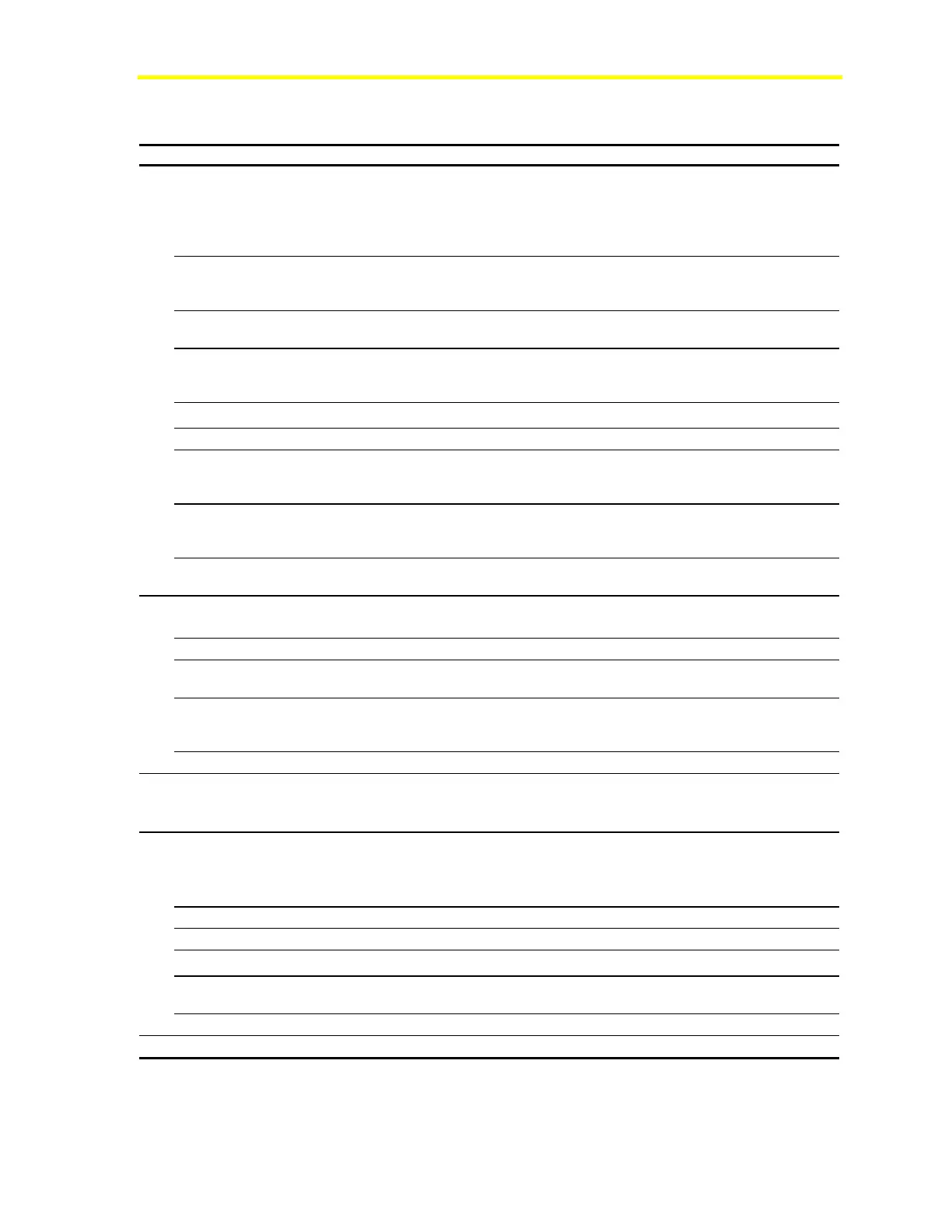

Table 1: VMA1400 Series Comparison Checklist

VMA Features 1410 1420 1430 Comments

Applications

Pattern Recognition Adaptive

Control (PRAC) on Zone Proportional

plus Integral plus Derivative (PID)

Temperature Loops

Y Y Y Eliminates manual tuning and

seasonal re-tuning

Adaptive Flow Control Loops

Y Y Y Eliminates manual tuning,

improves control and energy

savings

Single Duct, Pressure Independent

VAV

Y Y Y Meets most VAV applications

Side Loops without Interlocking

N Y Y Single Analog Input (AI) to Analog

Output (AO) or Binary Output

(BO)

Single Duct Supply/Exhaust VAV

N Y Y Flow differential control

Fan Powered Boxes

N Y Y Series or parallel

Incremental, Proportional

Two Position, and Three Stages of

Box Heat

N Y Y Staged heat or normally

open/normally closed valves

Incremental, Proportional

Two Position, or One Stage

Supplemental Heat

N Y Y Normally open or closed valves

Dual Duct, Pressure Independent

VAV

N Y Y Flexible flow setpoint specification

Damper Actuator (Internal)

Accurate Positioning

Y Y N/A 23,000 step resolution

Stall Detection

Y Y N/A Detects damper travel stops

Automatic Damper End Stop

Detection at Power Up

Y Y N Sets damper stroke time

Clockwise (CW)/

Counterclockwise (CCW)

Rotation Selection

Y Y Y Set via HVAC PRO™ software for

either direction to close

EP8000 with Pneumatic Actuator

N Y Y

Software Tools

Ability To Download Code Firmware

Y Y Y Allows firmware code upgrade

without removing the VMA

Diagnostics

Moving Average Flow/Temperature

Diagnostic

Y Y Y Provides standard measure of

control loop performance over

time

Actuator Stall

Y Y N/A

Flow Test

Y Y Y

Data Graphing

Y Y Y Only for single duct applications

Starved Box Detection

Y Y Y Allows air handler reset and flow

diagnostics

Actuator Duty Cycle Diagnostic

Y Y Y Indicates shaft slippage

Continued on next page . . .

Loading...

Loading...