4.0 Installation and maintenance

4.1 General

• Anchorthepumpproperly.

• Thepumpmustbeprovidedwithlockablecircuitbreakertoavoidinadvertant

starting.

• Beforeanyserviceormaintenanceinthepumporsystem,shutoffthepowerandlock

the starting device to prevent inadvertent start. Close the valves on the in- and outlet

line and drain the pump and system before it is separated from the system. Follow the

instructions for disassembly/assembly (see section 4.5).

4.2 Installation and piping

• Use at least the same diameter on pipes from and to the pump as for the diameter of

the in- and outlet ports.

• Flushallpipesbeforeinstallingthepump.

• Installthepumpclosestpossibletothetanktobepumpedfrom.

• Boltthepumpinplacehorizontally.

• Onlyuseplasticpipeconnections.

• Usecaretopreventscrapsortrashesfromenteringthepipingduringpipingwork.

• Onlyusepipesealantsformulatedspecicallyforplastics,i.e.Teontape,Permatex

no. 2, etc.

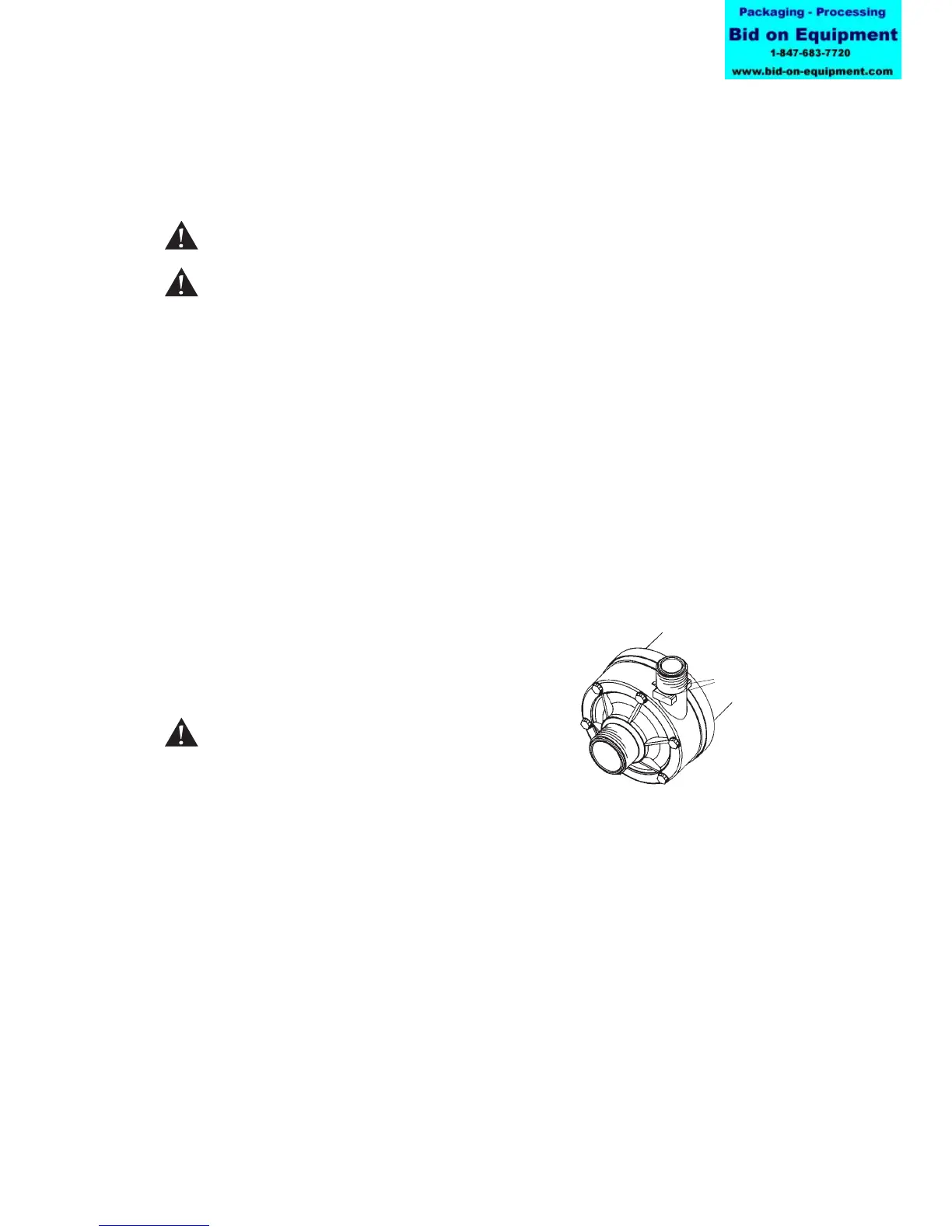

• Usethegriponthepumpoutletwhenassemb-

ling/disassembling the pipe connections to avoid

damaging the pump body (see fig).

• Installavalveonthesuctionandpressuresideto

be able to disconnect the pump from the system.

Make sure that the pump can be drained without

damaging persons, environment or equipment.

• Whenthepumpdoesnothaveaoodedsuction,installafootvalveonthesuction

line. Fill up the pump and evacuate all air. Make sure that it will never run dry.

• Ifthereisanyriskofairpocketsinthesystemorinthepumpbody,aventilatingvalve

must be installed on the pressure side.

• Ifthereisanyriskthatthedischargeheadwillnotreachtheminimumheadneeded

(see section 2.3), install a valve to adjust the head.

• Ifthereisanyriskofdryrunning,installasuitabledryrunningprotectiontoavoid

pump breakdown. This is absolutely necessary and required when pumping liquids that

are easily flammable.

Grip

Loading...

Loading...