• Thepumpunitmustnotbeexposedtorapidtemperaturechangesoftheliquid

without prior pre-heating/pre-cooling. Absolutely forbidden to flush a hot pump with

cold water. Big temperature changes can cause crack formation or explosion, which in

turn can entail severe personal injuries.

• Thepumpmustnotoperateabovestatedperformance.

• Beforeinterveninginthepump/system,thepowermustbeshutoffandthestarting

device be locked. When intervening in the pump unit, follow the instructions for

disassembly/assembly. If the instructions are not followed, the pump or parts of the

pump can be damaged. It will also invalidate the warranty.

• Ifthepumpdoesnotfunctionsatisfactorily,contactyourdistributor.

1.4 Type designation

Example

1 Family name

Magnetic Drive Centrifugal Pump

2 Pump size

45, 75, 85, 105, 116

3 Pump material

P2 = polyvinylidenfluoride (PVDF)

P3 = polypropylene (PP)

4 Impeller diameter

1V = full diameter for specific gravity up to 1.2 kg/dm

3

and viscosity 10 cP

1VD = reduced diameter for specific gravity up to 1.8 kg/dm

3

and viscosity 30 cP

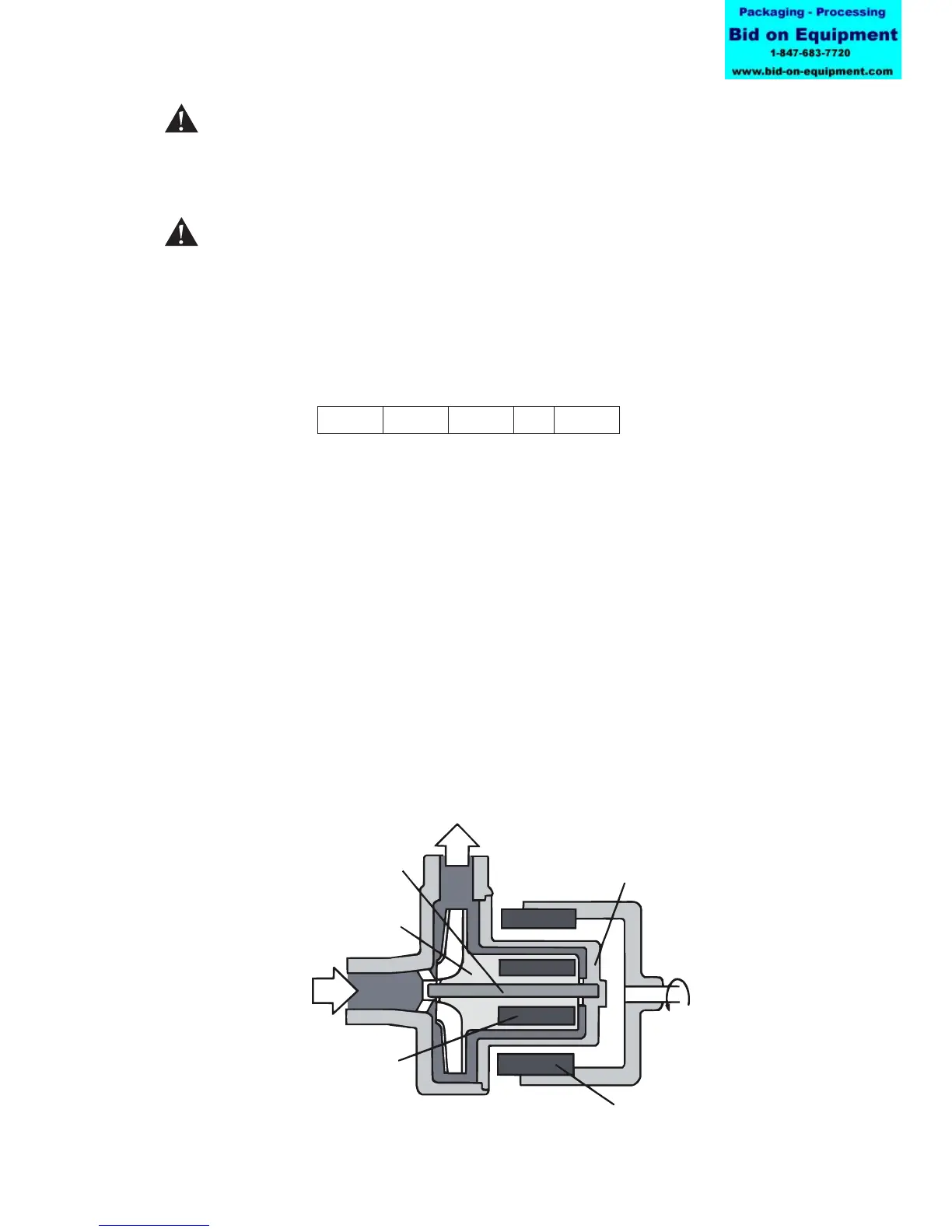

1.5 Function and operating principle

The drive magnet, attached to the drive shaft transfers its torque to the impeller magnet.

The impeller can thereby rotate around the ceramic shaft in the pump body without any

physical contact between the drive shaft and the pump body. This makes the pump

completely leak-proof.

Ceramic shaft

Impeller magnet

Impeller

Magnet housing

Drive shaft

Drive magnet

MDR 45 P2 - 1V

1 2 3 4

Loading...

Loading...