IMPORTANT: The inlet needle and float valve

seat must

be

replaced

as

a set.

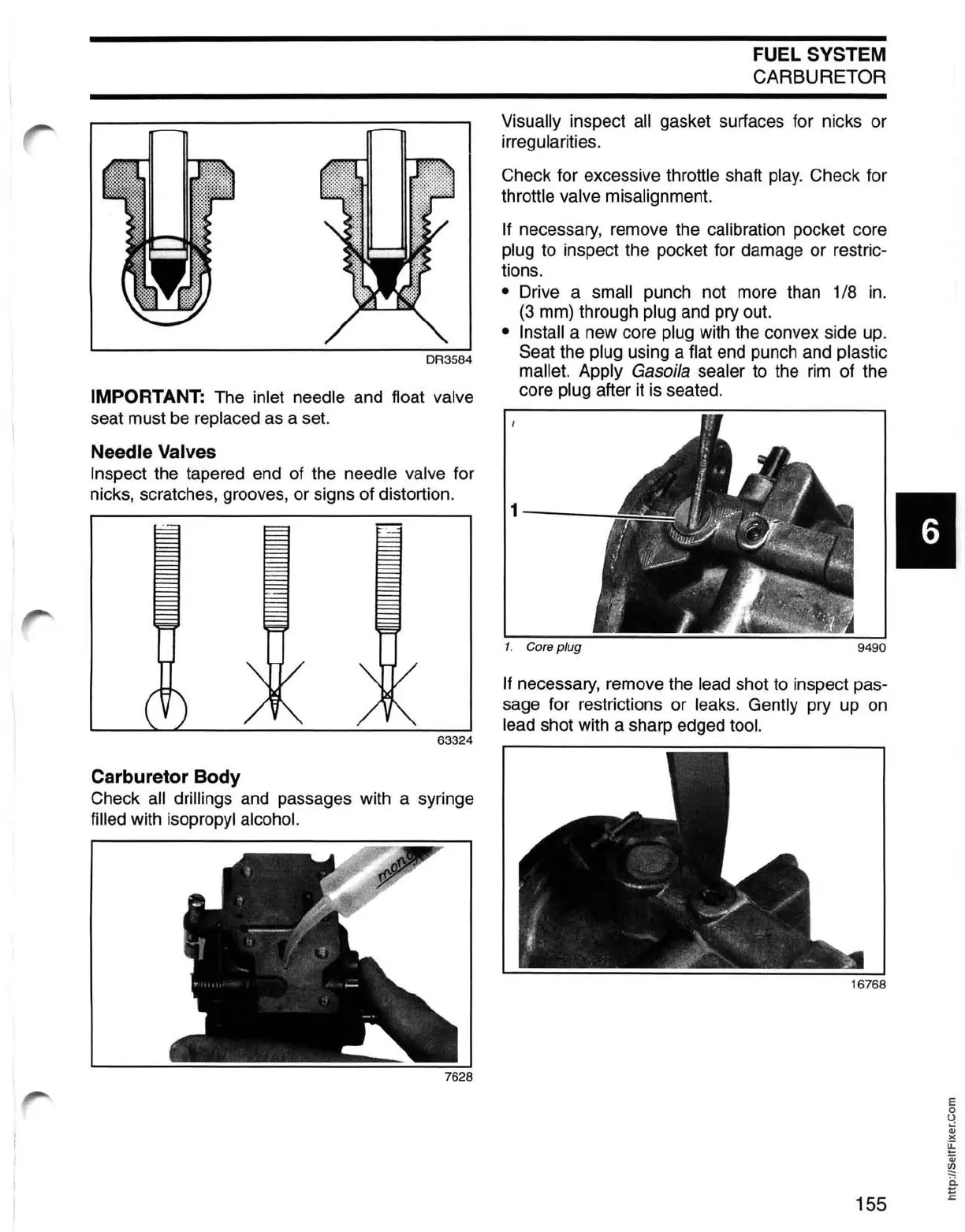

Needle Valves

Inspect the tapered end of the needle valve for

nicks, scratches, grooves, or signs of distortion.

63324

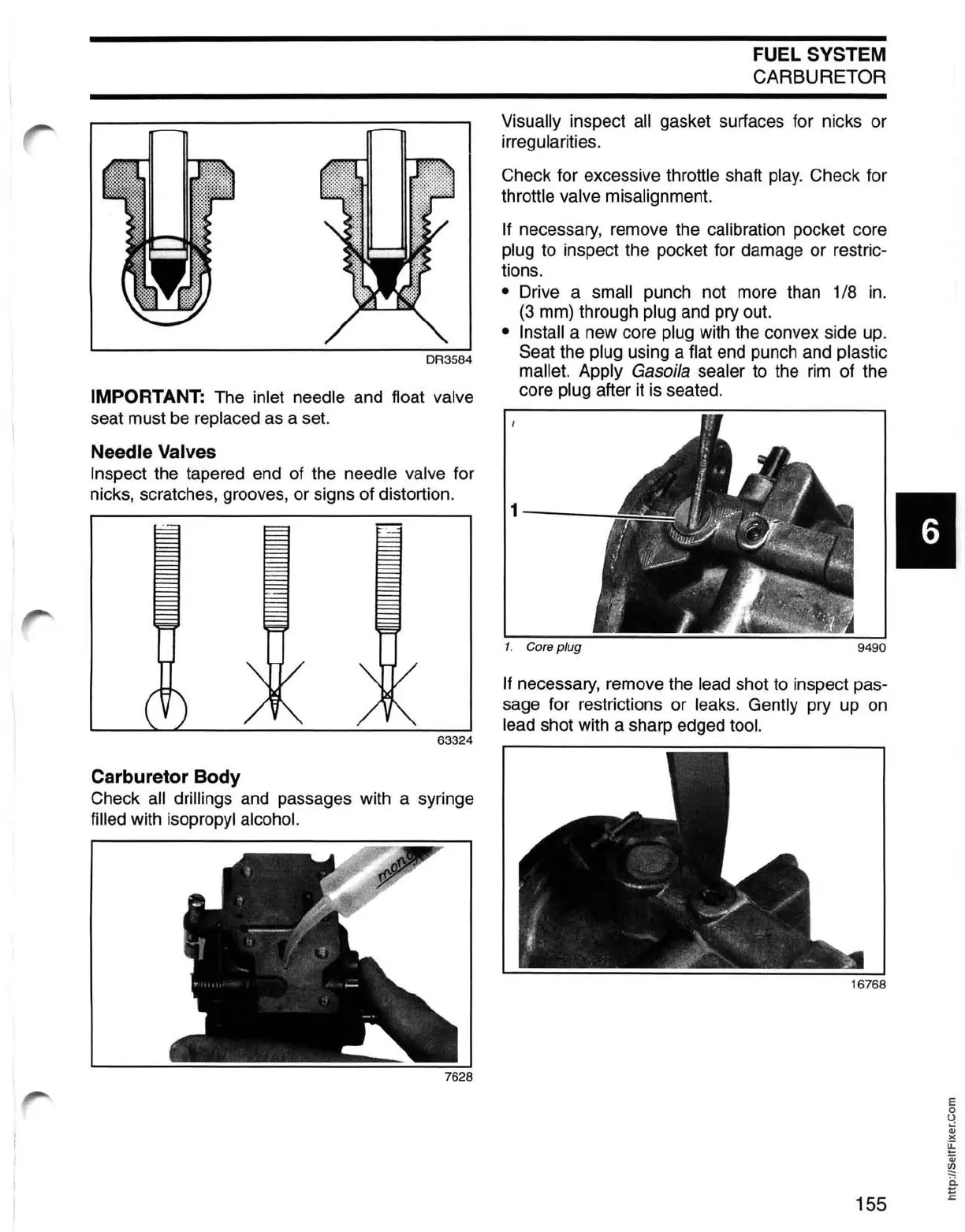

Carburetor Body

Check all drillings and passages with a syringe

filled with

isopropyl alcohol.

FUEL SYSTEM

CARBURETOR

Visually inspect all gasket surfaces for nicks or

irregularities.

Check for excessive

throttle shaft

play.

Check for

throttle valve misalignment.

If

necessary, remove the calibration pocket core

plug to inspect the pocket for damage or restric-

tions.

• Drive a small punch not more than 1/8 in.

(3

mm) through plug and pry out.

• Install a new core plug with the convex side

up.

Seat the plug using a flat end punch and plastic

mallet. Apply

Gasoila sealer to the

rim

of the

core

plug after

it

is

seated.

1--

__

~

1.

Core plug

9490

If

necessary, remove the lead shot to inspect pas-

sage for restrictions or

leaks. Gently pry up on

lead shot with a sharp edged tool.

16768

155

I

Loading...

Loading...