Check for correct positioning of the float level. The

float level controls the height of fuel

in

the float

chamber and

is

essential to carburetor calibration

and function.

Turn carburetor body upside down and

hold so

gasket surface

is

horizontal. The weight of the

float will close the float valve needle. Rest Float

Gauge,

PIN

324891,

on

gasket surface and slide

gauge

up,

next to float.

Top

of float should

be

between notches

on

gauge.

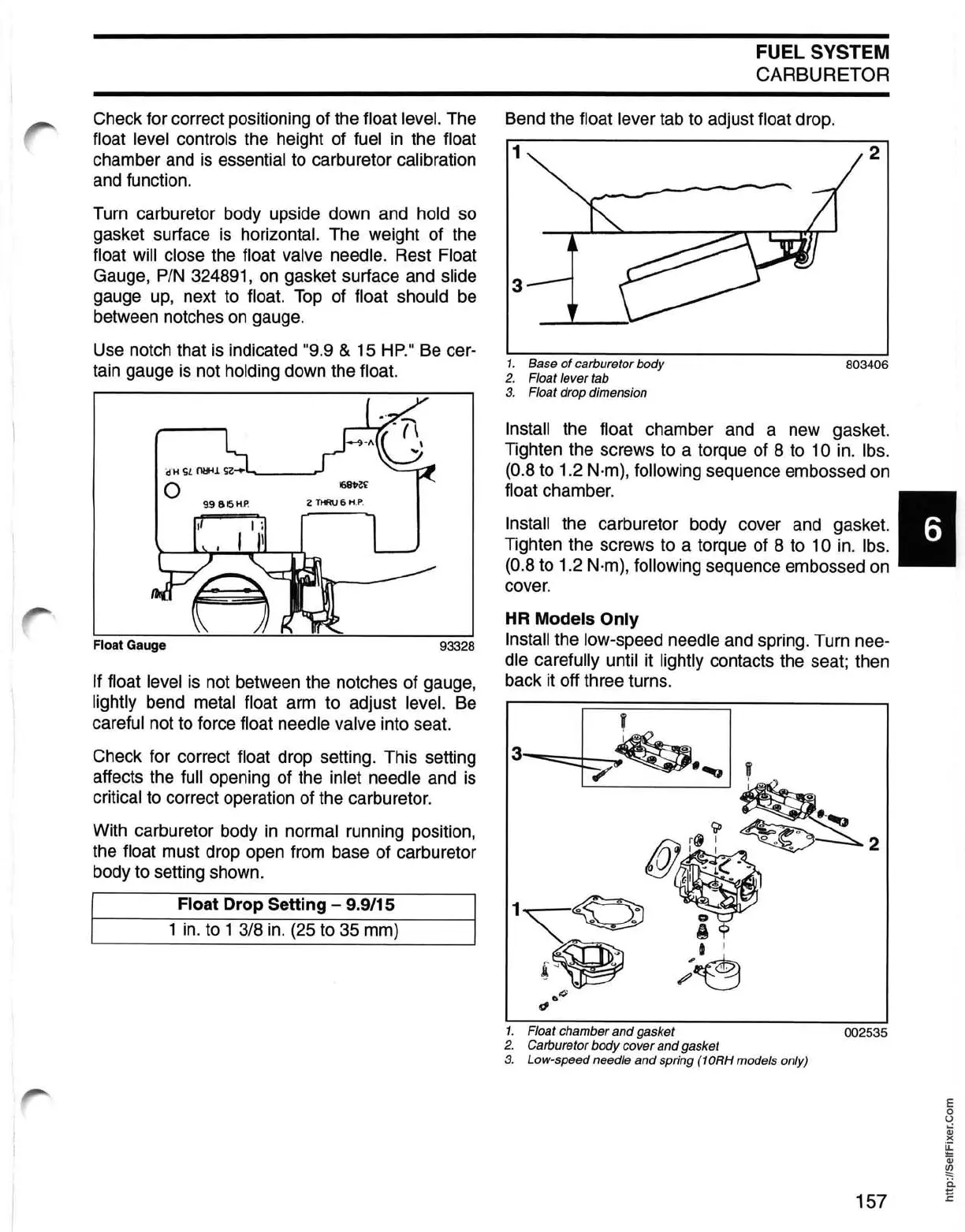

Use notch that

is

indicated "9.9 & 15 HP."

Be

cer-

tain gauge

is

not holding down the float.

o

99

&I5H

.

P.

Float Gauge

I681>lf

2

THRU6H

.P.

93328

If float level

is

not between the notches of gauge,

lightly bend metal float arm to adjust level.

Be

careful not to force float needle valve into seat.

Check for correct

float drop setting. This setting

affects the

full opening of the inlet needle and

is

critical to correct operation of the carburetor.

With carburetor body

in

normal running position,

the

float must drop open from base of carburetor

body to setting shown.

Float Drop Setting - 9.9/15

1

in.

to 1 3/8

in.

(25 to 35 mm)

FUEL SYSTEM

CARBURETOR

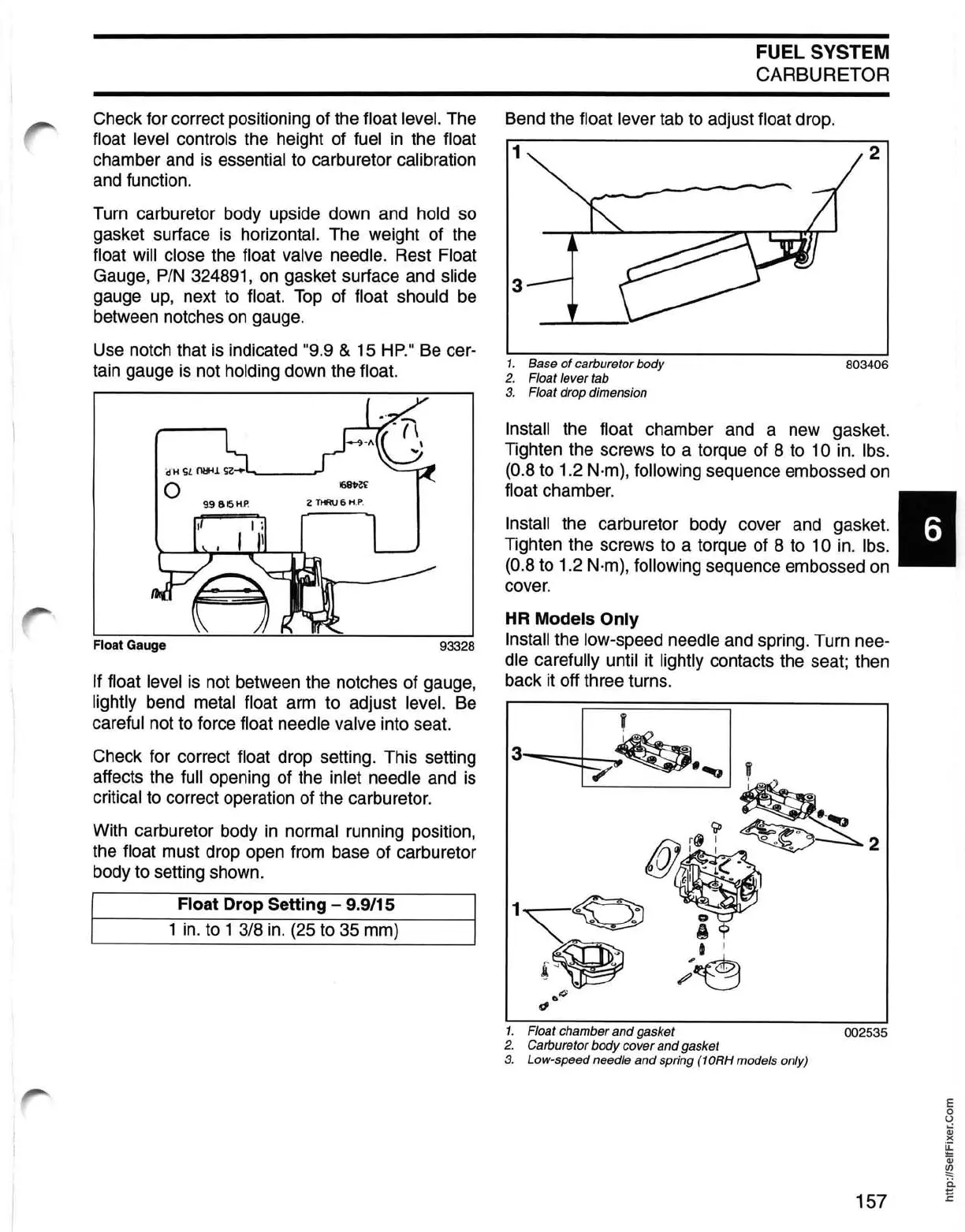

Bend the float lever tab to adjust float drop.

1

2

3

1.

Base

of

carburetor body

803406

2. Float lever tab

3.

Float drop dimension

Install the float chamber and a new gasket.

Tighten the screws to a torque

of

8 to 10 in. Ibs.

(0.8

to 1.2 N·m), following sequence embossed on

float chamber. 6

Install the carburetor body cover and gasket.

Tighten the screws to a torque of 8 to

10 in.

Ibs.

(0.8 to 1.2 N·m), following sequence embossed on

cover.

HR

Models Only

Install the low-speed needle and spring. Turn nee-

dle carefully until it lightly contacts the seat; then

back it off three turns.

1. Float chamber and gasket

002535

2. Carburetor body cover and gasket

3. Low-speed needle and spring

(10RH models only)

E

o

U

Qj

)(

~

Qj

~

ii

157 E

Loading...

Loading...