POWERHEAD

ASSEMBLY - 9.9/15

When the crankcase

is

seated, install and firmly

seat the crankcase taper pin.

Using a soft face

mallet, lightly tap bottom of the

crankshaft to seat the

lower main bearing.

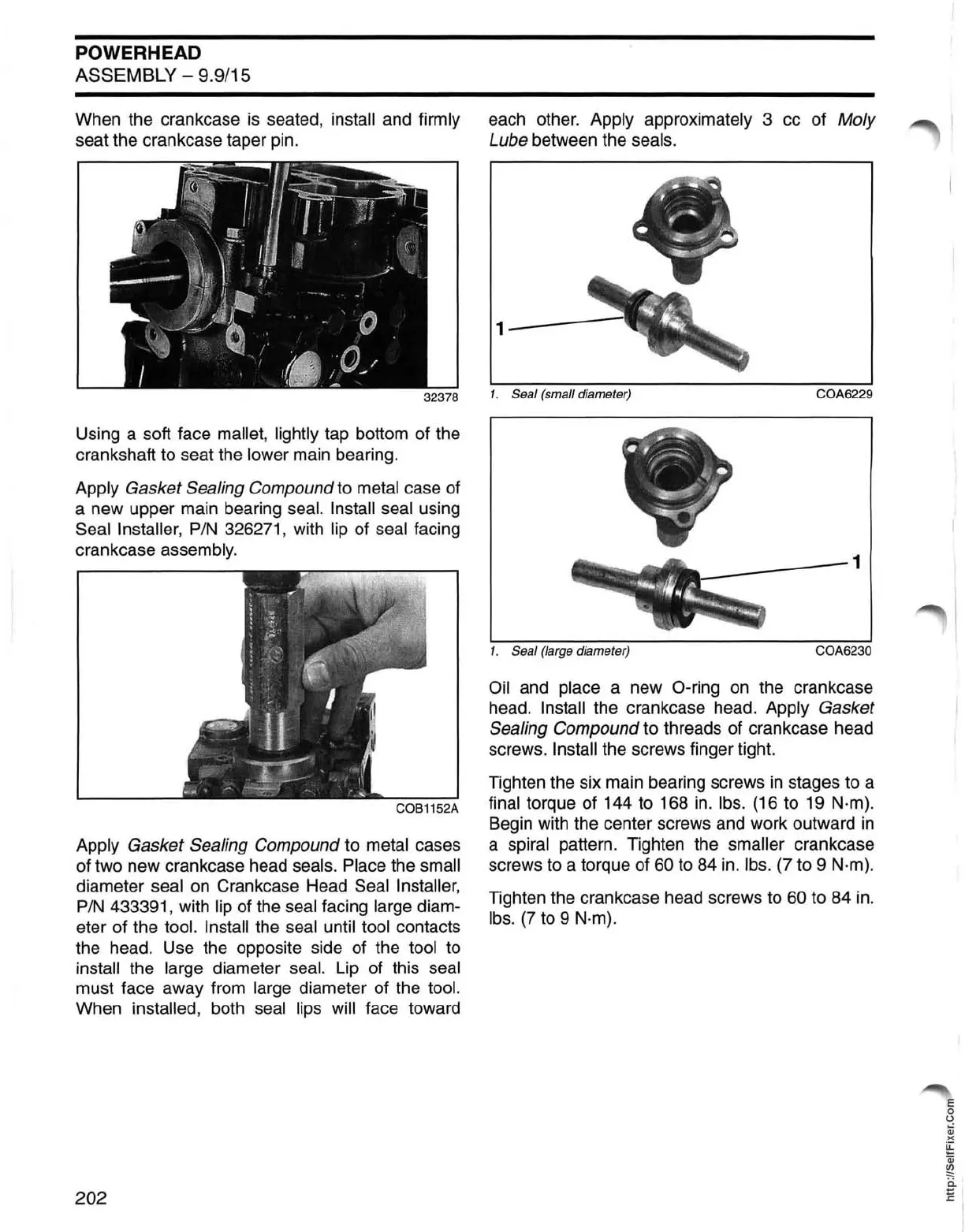

Apply Gasket Sealing Compound to metal case of

a new upper main bearing

seal. Install seal using

Seal Installer,

PIN

326271, with lip of seal facing

crankcase

assembly.

COB1152A

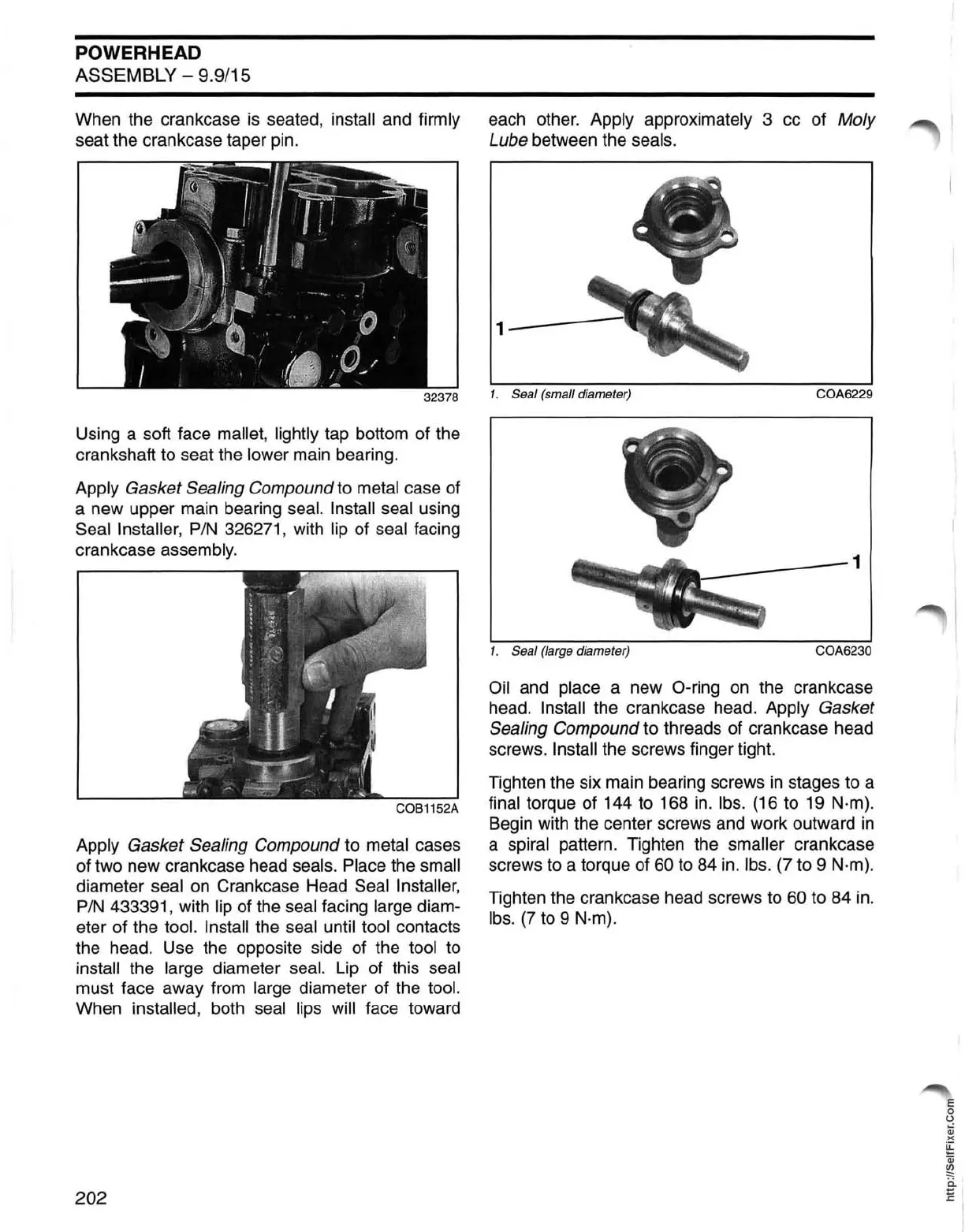

Apply Gasket Sealing Compound

to

metal cases

of two new crankcase head

seals. Place the small

diameter seal

on

Crankcase Head Seal Installer,

PIN

433391, with lip of the seal facing large diam-

eter of the

tool. Install the

seal

until tool contacts

the head. Use the opposite side of the

tool to

install the large diameter seal. Lip of this seal

must face away from large diameter of the tool.

When installed, both seal lips will face toward

202

each other. Apply approximately 3 cc of Moly

Lube

between the seals.

1-----

1. Seal (small diameter)

COA6229

__

----1

1. Seal (large diameter) COA6230

Oil

and

place a new O-ring

on

the crankcase

head.

Install the crankcase head. Apply Gasket

Sealing Compound

to threads of crankcase head

screws.

Install the screws finger tight.

Tighten the six main bearing screws

in

stages to a

final torque of 144 to 168

in.

Ibs.

{16

to 19 N·m}.

Begin with the center screws and work outward

in

a spiral pattern. Tighten the smaller crankcase

screws

to

a torque of

60

to

84

in.

Ibs.

{7

to 9 N·m}.

Tighten the crankcase head screws

to

60 to 84

in

.

Ibs.

(7

to

9 N·m).

Loading...

Loading...