(5) Prospector 500 PSI Carpet Extractor with Heat

5.0 Maintenance

Regular maintenance is required to keep your Prospector Carpet Extractor in proper working condition. Failure to

properly maintain your machine could void warranty. Thoroughly clean all equipment and accessories after each use:

• Rinse the solution and recover tanks with clean water.

• Flush the pump system with clean water, including all hoses and wand(s).

• Do not allow water to remain in the tanks after use.

• Lubricate all quick disconnects with WD-40 or similar lubricant.

• Clean vacuum oat assembly screen.

WARNING: Disconnect electrical power cord before performing any service or maintenance inside the machine base or

before testing or repairing switches or power cords. Failure to do so may result in severe personal injury or death.

Operation Interval

Clean Chemical Feed Filter Daily- After Each Job

Clean Vacuum Assembly Screen Daily- After Each Job

Rinse Out Recovery Tank Daily

Flush Solution Tank and Pump Daily

Clean Pump-Inlet Filter Weekly - As Needed

5.1 Clean Fresh Water Tank Filter

The fresh water tank lter is located at the bottom of the solution tank. Unscrew the lter counterclockwise and rinse with

fresh water. If necessary, use a tooth brush to remove detergent build-up. Note, a heavy build-up is a warning sign that the

solution system should be ushed. See the “Flush Chemical System” section.

5.2 Clean Vacuum Float Assembly Screen

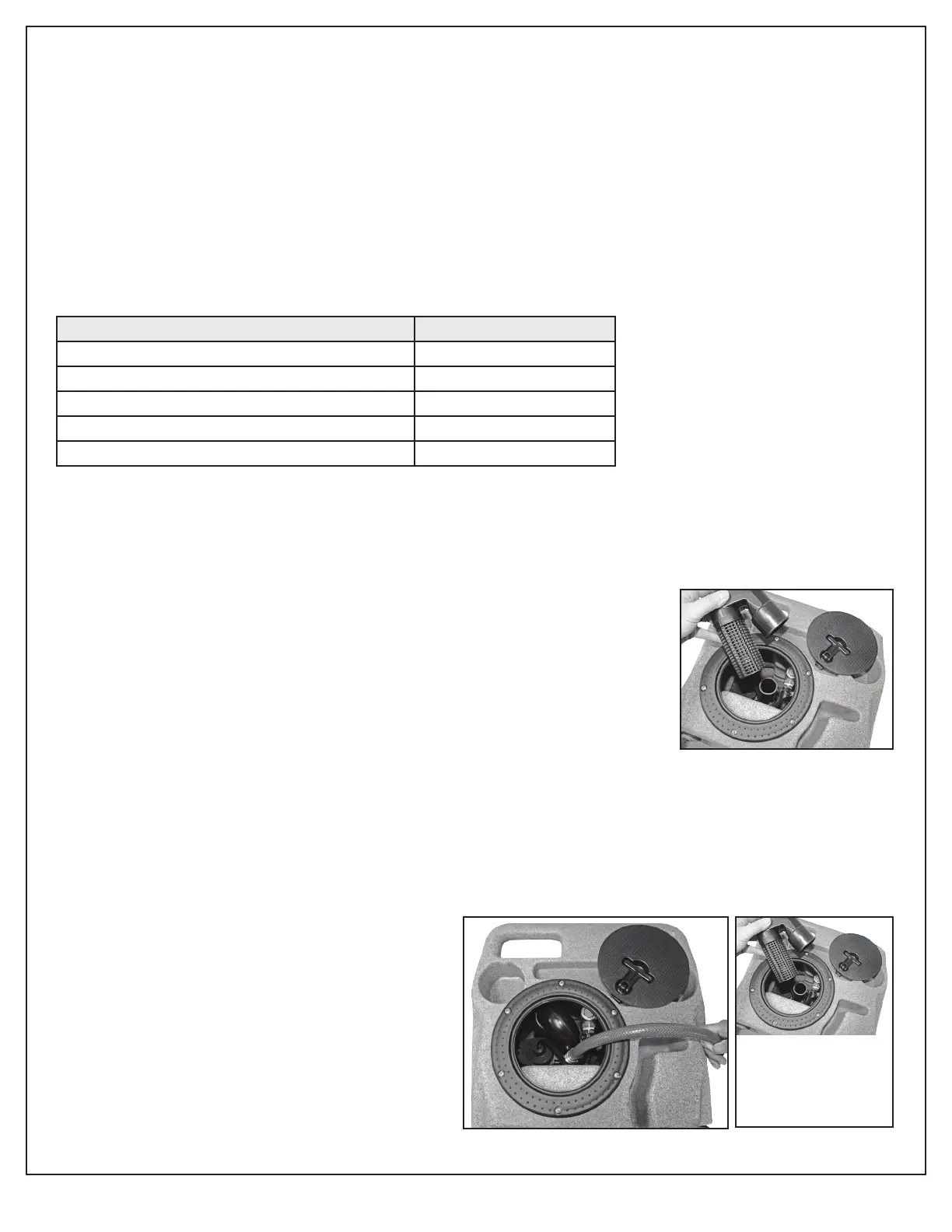

Inside the recovery tank, on top of the stand pipe, is the vacuum oat assembly. It

functions to prevent debris and water from being sucked into the vacuum motors.

Operating the Prospector Carpet Extractor without the oat assembly or with a poorly

maintained assembly, will greatly decrease the life of the vacuum motors and will void the

warranty.

If debris builds up on this lter, it will reduce the vacuum air ow and may cause a

signicant decrease in the rate of water recovery. If debris prevents the oat ball from

moving or seating inside the assembly, it may not stop the airow when the tank lls with

water and the water will be sucked in the vacuums and blow out the exhaust.

To clean, twist off the oat assembly from the stand pipe and clean the screen. Pull bers and lint off and rinse with clean

water. Push the assembly back onto the stand pipe and replace the recovery tank lid.

This screen should be cleaned frequently if the Prospector Carpet Extractor is being operated in an environment which

has an abnormal build-up of lint and debris, such as cleaning newly installed carpet. Loss of vacuum is most normally

associated with lint build-up in this lter at the top of the vacuum stand pipe.

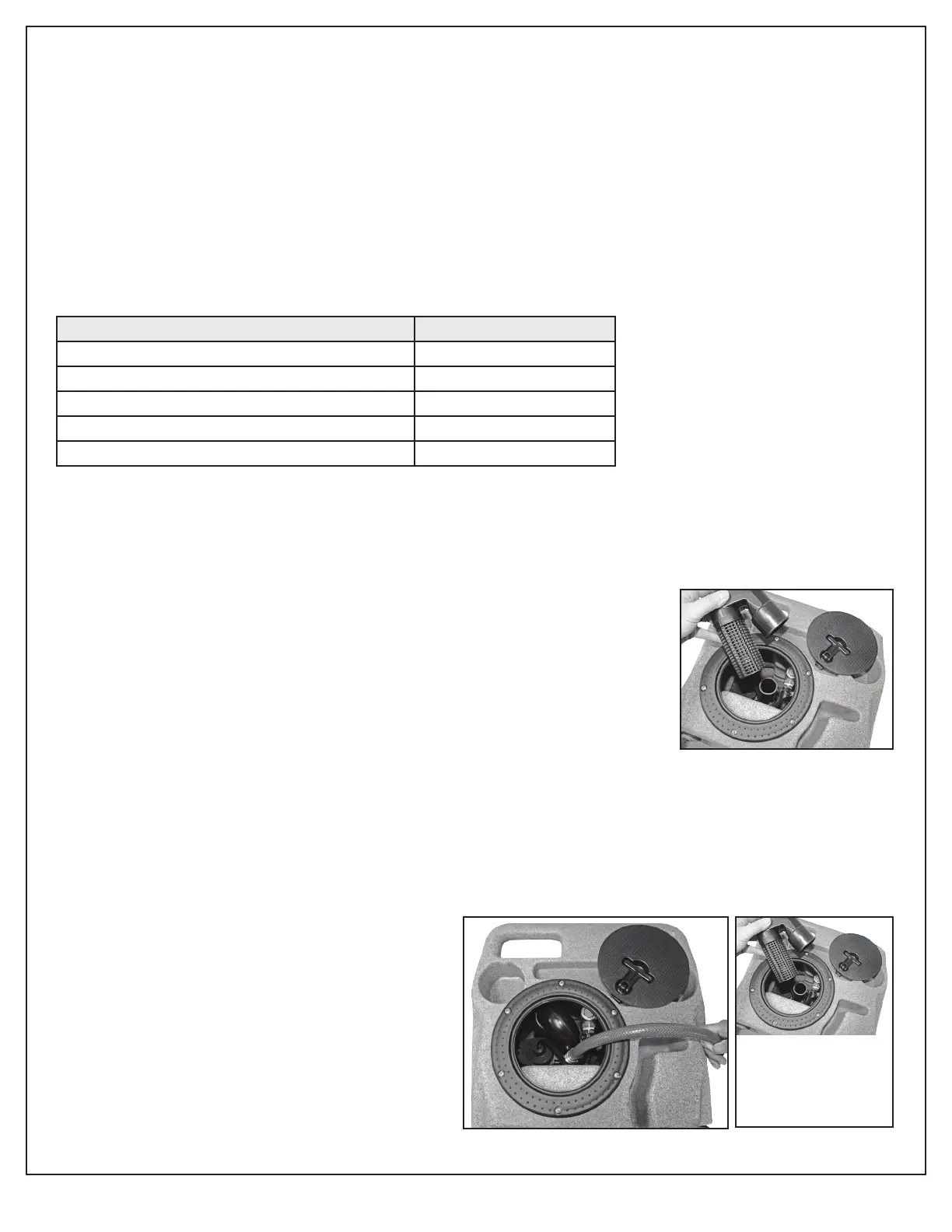

5.3 Rinse Out Recovery Tank

Build-up of ne silt and debris can damage the auto-

dump pump and dump valve. Clean out the recovery

tank on a regular basis to extend the life of these

components as well as keep the tank and machine

smelling better.

To rinse out recovery tank, remove the recovery tank

lid and open the dump valve. Place a bucket under the

dump valve. Use a hose to rinse the dirt and debris

out of the recovery tank. Close the dump valve and

spray the tank with deodorizer or disinfectant. Proceed to waste pump cleaning and replace the recovery tank lid. Dispose

of dirty water and debris.

Vacuum Float Assembly

Loading...

Loading...