protection to seal the edges of the openings in the

vehicle floor. To prevent the tubing and oil pump cable

from being broken, add a bushing or cross-section edge

protection material.

The tubing should be bundled and secured at a suitable

location with a bundling distance of no more than 50 cm.

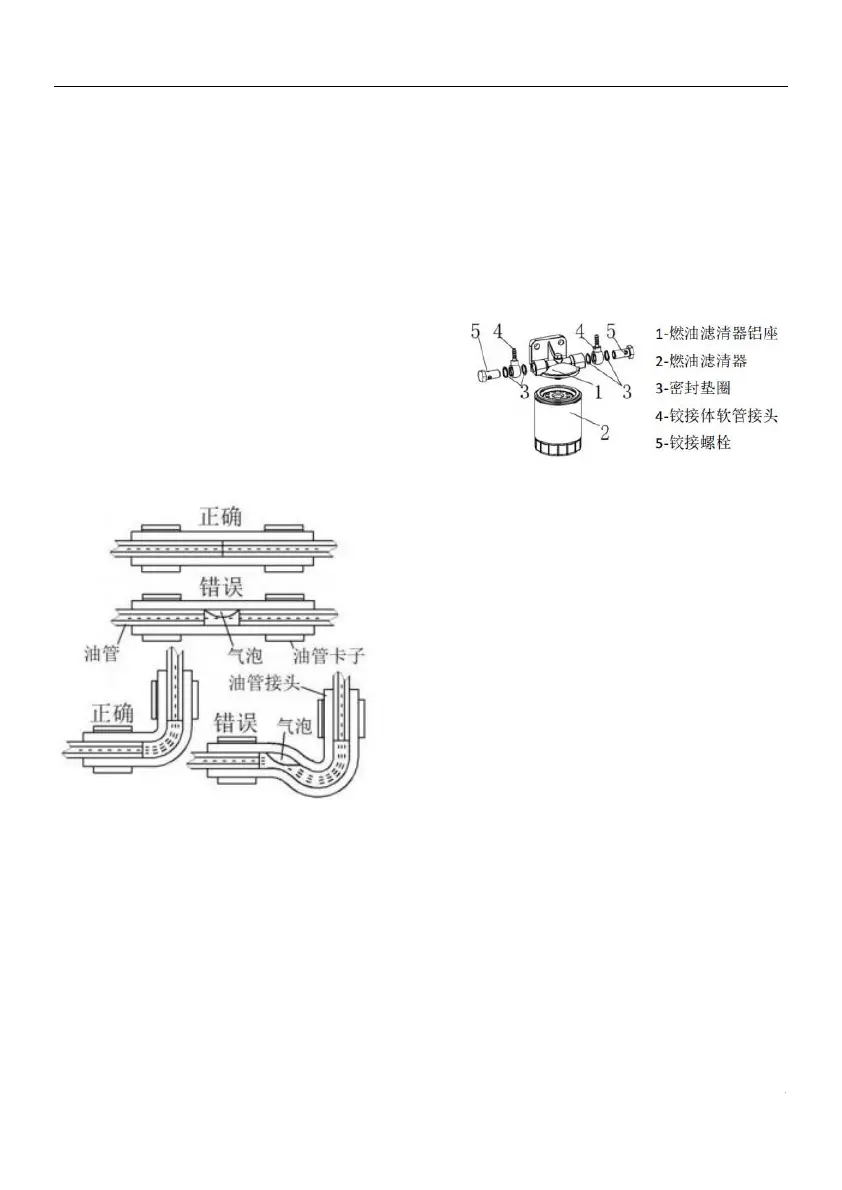

The connection between the oil pipe and the oil pump,

the main engine, and the fuel tank (the nozzle) should be

made with the oil pipe joint of the machine and clamped

with the oil pipe clamp. Prevent bubbles from forming at

the joint (Figure 15).

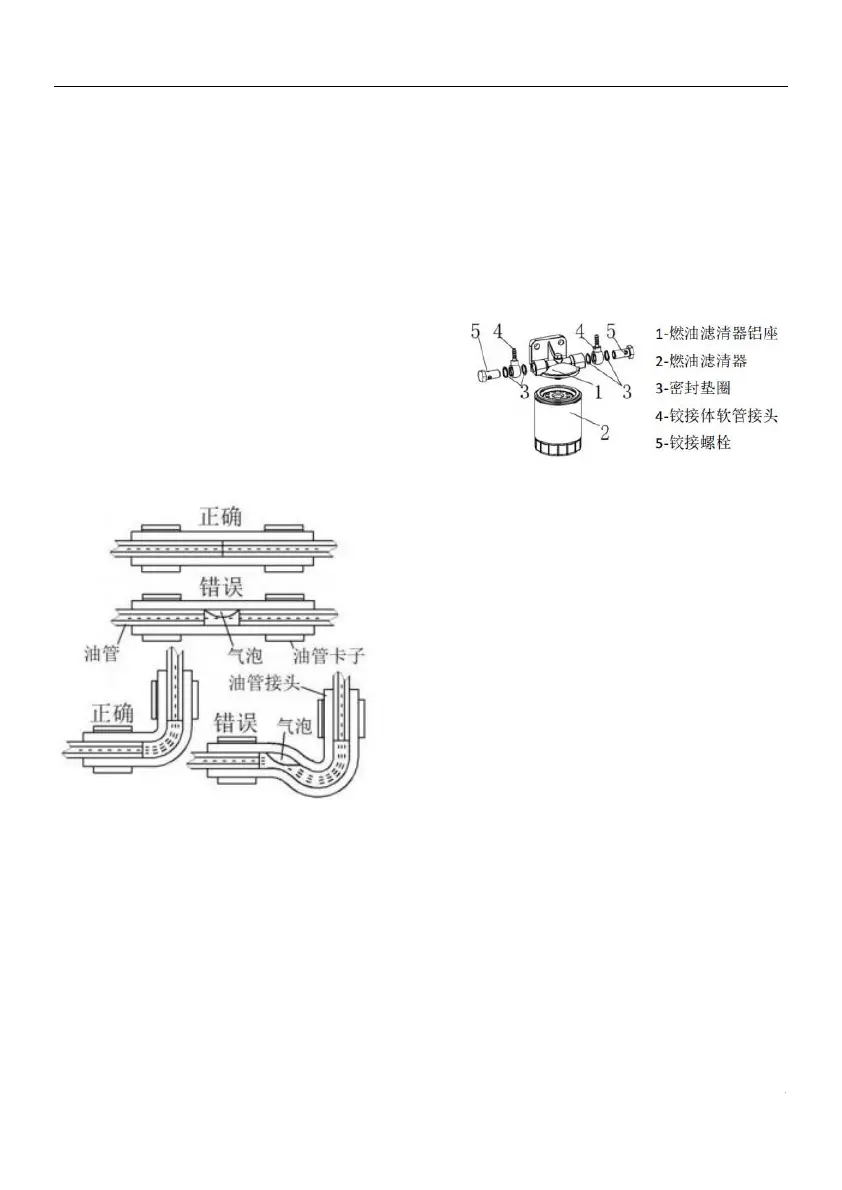

Fuel Filter Installation

Install the fuel filter in front of the fuel inlet of the fuel

pump. When installing, be aware that the fuel filter must

be vertically up (to ensure that the impurities are

deposited downward).

The fuel filter replacement cycle is two years, and the

tubing joints and clamps must be replaced at the same

time.

Installation of the nozzle (Fig. 17)

Put the nozzle on the O-ring first, and then pass it out

from the inside of the tank through the bottom φ8 hole

(can be processed by itself). Put a washer on the outside

of the tank and tighten with a nut. The tightening torque

is 6Nm+1Nm.

The O-ring must be sandwiched between the inner side

wall of the tank and the nozzle to ensure a good seal

between the nozzle and the tank. (The accessories such

as the nozzle are included in the fuel tank)

Loading...

Loading...