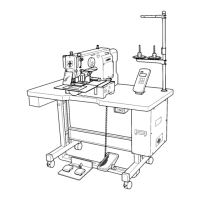

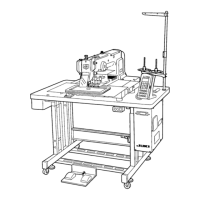

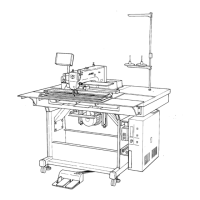

This document describes the JUKI AMS-210E series sewing machine, a specialized industrial sewing machine designed for various pattern sewing applications. It covers the mechanical and operational aspects of the machine, including installation, preparation, basic and advanced operation, and maintenance.

Function Description

The AMS-210E is a programmable pattern sewing machine capable of sewing complex shapes and patterns. It features a double-capacity semi-rotary hook for efficient thread handling and a stepping motor-driven intermittent feed system for precise fabric movement. The machine can store a significant number of patterns, either in its internal EEP-ROM (up to 200 patterns, 20,000 stitches/pattern) or on Smart Media (up to 999 patterns, 50,000 stitches/pattern).

Key functions include:

- Pattern Sewing: The primary function, allowing users to select and sew pre-programmed or custom patterns.

- Enlarging/Reducing Facility: Patterns can be scaled independently on the X and Y axes from 1% to 400% (0.1% steps), either by adjusting stitch length or the number of stitches.

- Temporary Stop Facility: Allows the machine to pause operation during a stitching cycle for adjustments or interventions.

- Bobbin Thread Counter: Tracks bobbin thread usage, with UP/DOWN counting from 0 to 9,999.

- Sewing Counter: Monitors the number of sewing cycles performed (UP/DOWN method, 0 to 9,999, IP-400 only).

- Memory Back-up: Automatically stores the current pattern in memory in case of a power interruption.

- 2nd Origin Setting: Users can set a secondary origin (needle position after a sewing cycle) within the sewing area using jog keys, which is also stored in memory.

- Needle Highest Position Stop Facility: After sewing completion, the needle can be brought to its highest position.

- Thread Clamp Device: Prevents thread slip-off, stitch skipping, and thread stains at high-speed starts, reducing "bird's nests" on the wrong side of the fabric. It ensures stable sewing by clamping the needle thread.

- Combination Sewing: Allows for combining multiple pattern data to sew complex sequences, with up to 30 patterns inputtable and 20 combination sewing data registrable.

- Communication Function: Enables downloading and uploading sewing data from other JUKI machines, editing devices (PM-1), or personal computers via Smart Media or RS-232C port.

Important Technical Specifications

- Sewing Area (X x Y):

- AMS-210E-1306: 130 mm x 60 mm

- AMS-210E-1510: 150 mm x 100 mm

- AMS-210E-2206: 220 mm x 60 mm

- Max. Sewing Speed: 2,700 rpm (for stitch pitch 3 mm or less)

- Stitch Length: 0.1 to 12.7 mm (Min. resolution: 0.05 mm)

- Needle Bar Stroke: 41.2 mm

- Needle Type: DP x 5, DP x 17

- Lift of Feeding Frame: Max. 25 mm (Pneumatic type only Max. 30 mm)

- Intermediate Presser Stroke: 4 mm (Standard) (0 to 10 mm)

- Lift of Intermediate Presser: 20 mm

- Intermediate Presser DOWN Position Variable: Standard 0 to 3.5 mm (Max. 0 to 7.0 mm)

- Shuttle: Double-capacity semi-rotary hook

- Lubricating Oil: New Defrix Oil No. 2 (Supplied by oiler)

- Max. Sewing Speed Limitation: 200 to 2,700 rpm (100 rpm steps)

- Sewing Machine Motor: 550W servo-motor

- Dimensions (W x L x H): 1,200 mm x 710 mm x 1,200 mm (Excluding thread stand)

- Mass (Gross Mass): Machine head 69 kg, control box 16.5 kg

- Power Consumption: 500 VA

- Operating Temperature Range: 5°C to 35°C

- Operating Humidity Range: 35% to 85% (No dew condensation)

- Line Voltage: Rated voltage ±10% 50 / 60 Hz

- Air Pressure Used (Pneumatic Type Only): Standard 0.35 to 0.4 MPa (Max. 0.55 MPa)

- Air Consumption (Pneumatic Type Only): 1.8 dm³/min (ANR)

- Noise: Workplace-related noise at sewing speed n = 2,700 min⁻¹: LPA ≤ 84 dB(A) (according to DIN 45635-48-B-2-KL2)

Usage Features

The AMS-210E can be operated via two types of control panels: IP-400 (LCD touch panel) or CP-20 (LED/7-segment display).

IP-400 (LCD Touch Panel):

- Intuitive Interface: Features a touch panel LCD for easy navigation and data input.

- Pattern Selection: Allows selection of patterns from EEP-ROM, Smart Media (Vector format, M3 data, Sewing standard format), and user-registered patterns.

- Item Data Changing: Users can adjust X/Y scale rates, thread tension, maximum sewing speed, and intermediate presser height.

- Temporary Stop: Provides options to continue sewing from a specific point or re-sew from the start after a temporary stop.

- Bobbin Winding: Can wind bobbin thread while sewing or independently.

- Counter Function: Includes sewing counter and bobbin thread counter with UP/DOWN methods and settable values.

- Pattern Registration: New user patterns and pattern buttons can be registered and named.

- Combination Sewing: Facilitates the creation and selection of combination sewing data.

- Memory Switch Data: Allows changing various machine settings via memory switches.

- Information Display: Provides maintenance, inspection, production control, and working measurement information.

- Communication: Supports data transfer via Smart Media and RS-232C.

CP-20 (LED/7-segment Display):

- Basic Operation: Provides essential controls for pattern selection, X/Y scale, max. sewing speed, thread tension, and intermediate presser height.

- Pattern Registration: Allows registering patterns to specific keys (P1-P25) for one-touch selection.

- Bobbin Winding: Supports bobbin winding operations.

- Bobbin Thread Counter: Can be used as a bobbin thread counter with a subtracting method, stopping the machine when the specified number of stitches is reached.

- Memory Switch: Enables changing memory switch settings.

Maintenance Features

Regular maintenance is crucial for optimal machine performance and longevity.

- Lubrication: The hook portion requires lubrication with New Defrix Oil No. 2. The oil tank level should be maintained between lines A and B. Excessive oil in the hook portion should be avoided.

- Needle Attachment: Needles (DP x 5, DP x 17) must be securely attached with the long groove facing the operator.

- Bobbin Case and Bobbin Installation: Proper installation ensures consistent thread pulling and prevents issues during sewing.

- Thread Tension Adjustment: Adjustable via the operation panel and bobbin thread tension controller to achieve desired stitch quality.

- Intermediate Presser Height Adjustment: Ensures proper clearance between the presser and fabric (0.5 mm) when the needle is at its lowest position.

- Thread Take-up Spring Adjustment: Controls the moving amount and thread drawing amount, affecting thread pressure.

- Drain Receiver and Head Support Rubber Installation: Essential for managing waste and supporting the machine head.

- Safety Switch: Ensures the machine does not operate when tilted, preventing accidents.

- Throat Plate Auxiliary Cover Installation: Prevents needle breakage and defective feed by ensuring proper alignment with the throat plate.

- Electrical Box and Power Switch Installation: Proper connection and securing of electrical components.

- Motor Cover Installation: Protects the motor and internal components.

- Cord Management: Cords must be fixed to prevent stress and interference during machine operation.

- Pneumatic Components (Pneumatic Type Only): Regulator and solenoid valve assembly installation, air hose connection, and air pressure adjustment (0.35 to 0.4 MPa).

- Eye Protection Cover: Must be attached to protect against needle breakage.

- Moving Knife and Counter Knife Adjustment: Ensures proper thread trimming.

- Needle Thread Clamp Device Adjustment: Ensures correct operation for stable sewing.

- Thread Breakage Detector Plate Adjustment: Ensures proper contact with the thread take-up spring.

- Draining Waste Oil: Regular draining of waste oil from the drain bin.

- Amount of Oil Supplied to the Hook: Adjustable to prevent excessive lubrication.

- Fuse Replacement: Instructions for replacing fuses (15A, 3.15A, 2A) in the control box.

- Voltage Changeover: Procedure for changing voltage settings (100V/200V).

- Grease Replenishment: Specific points for grease application (eccentric cam section, oscillator pin section, face plate felt section, X guide shaft bearing) to prevent wear and tear. The machine provides warnings (E220, E221) when grease replenishment is due.

- Troubleshooting: A comprehensive list of error codes and corrective measures for common sewing conditions and machine malfunctions.