1

6.

LUBRICATION

I

--

1

1.

'

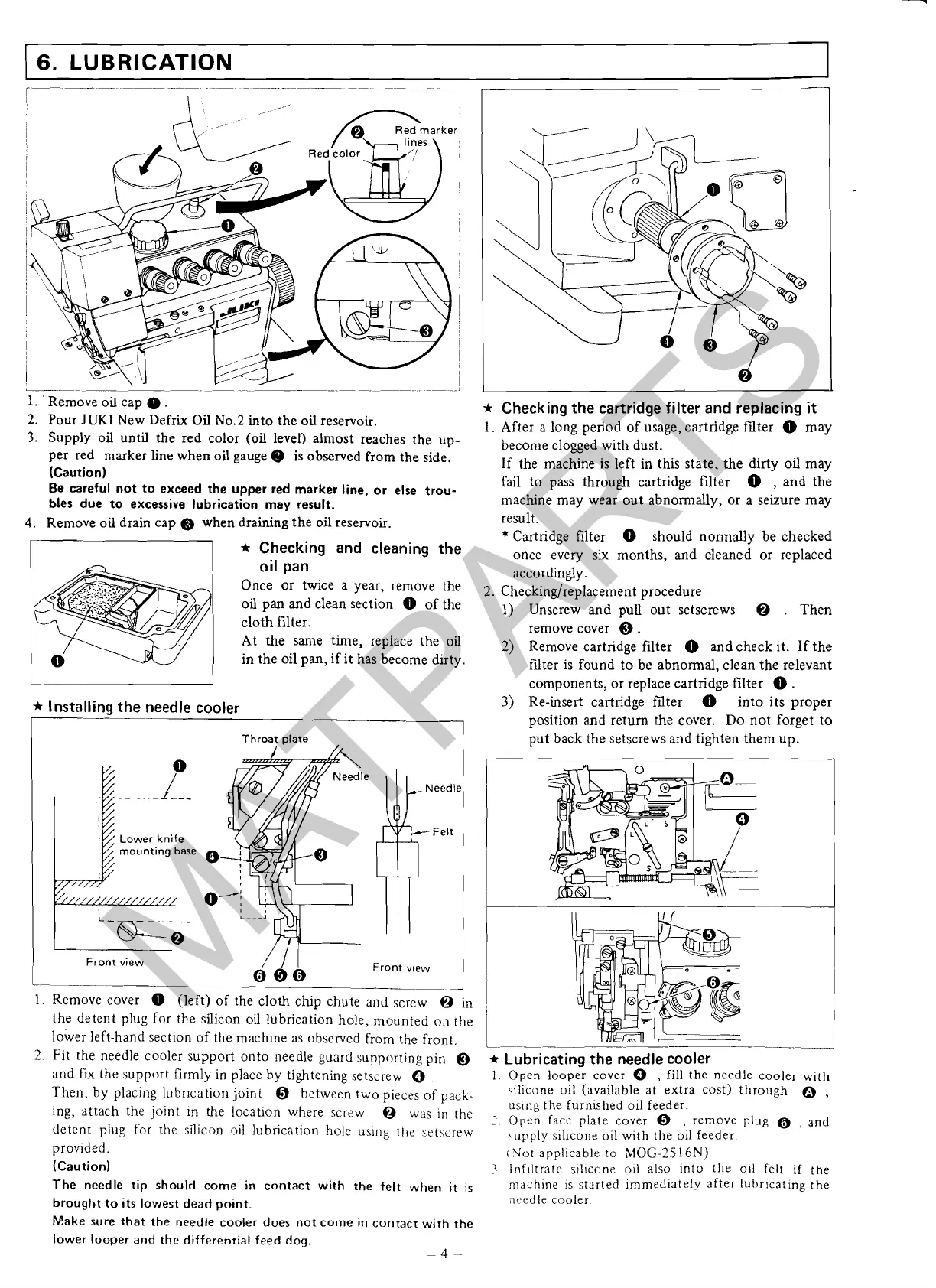

Remove oil cap

0

.

2. Pour JUKl New Defrix Oil No.2 into the oil reservoir.

3.

Supply oil until the red color (oil level) almost reaches the up-

per red marker line when oil gauge

@

is

observed from the side.

(Caution)

Be careful not

to

exceed the upper red marker line, or else trou-

bles due to excessive lubrication may result.

4.

Remove oil drain cap

@

when draining the oil reservoir.

-1

*

Checking and cleaning the

oil pan

Once or twice a year, remove the

oil pan and clean section

0

of the

cloth filter.

At the same time, replace the oil

1

0

I

in the oil pan, if it has become dirty.

*

Installing the needle cooler

1--

Throat plate

mounting base

I

1

Front view

Needle

Felt

/

I

I

000

Front

view

I

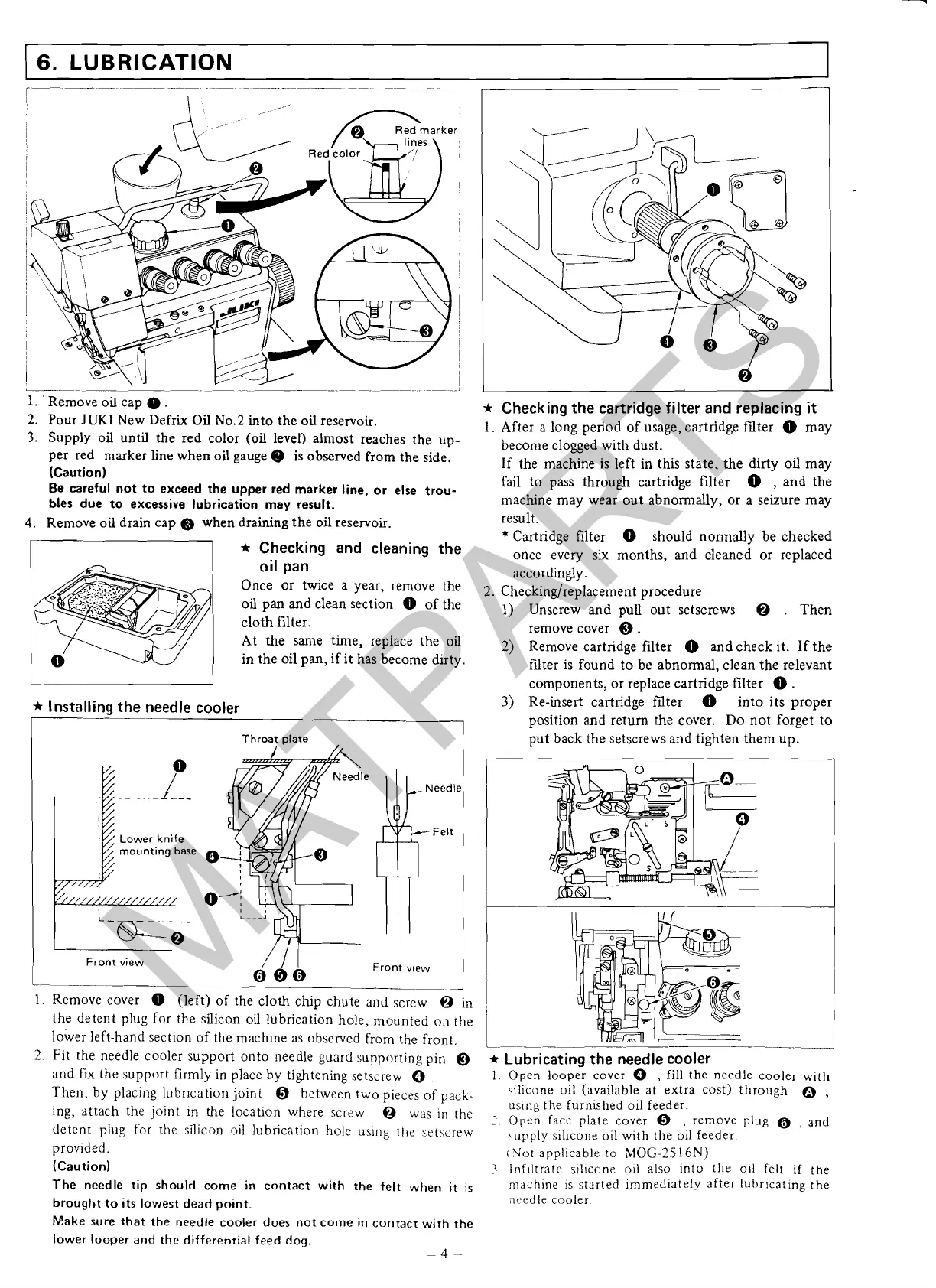

1.

Remove cover

0

(left) of the cloth chip chute and screw

@

in

the detent plug for the silicon oil lubrication hole, mounted on the

lower left-hand section of the machine as observed from the front.

*

Checking the cartridge filter and replacing

it

1.

After a long period of usage, cartridge filter

0

may

become clogged with dust.

If the machine is left in this state, the dirty oil may

fail to pass through cartridge filter

0

,

and the

machine may wear out

abnormally, or a seizure may

result.

*

Cartridge filter

0

should normally be checked

once every six months, and cleaned or replaced

accordingly.

2.

Checking/replacement procedure

1)

Unscrew and pull out setscrews

@

.

Then

remove cover

Q

.

2)

Remove cartridge filter

0

and check it. If the

filter is found to be abnormal, clean the relevant

2.

Fit the needle cooler support onto needle guard supporting pin

Q

and

fix

the support firmly in place by tightening setscrew

0

Then, by placing lubrication joint

@

between two pieces of pack-

ing, attach the joint in the location where screw

@

was ln the

detent

plug

for the silicon oil lubrication hole using tile setscrew

provided.

(Caution)

The needle tip should

come

in

contact with the felt when it is

brought to its lowest dead point.

Make

sure that the needle cooler does not come in contact with the

components, or replace cartridge filter

0

.

3)

Re-insert cartridge filter

0

into its proper

position and return the cover.

Do not forget to

put back the setscrews and tighten them up.

-

-

*

Lubricating the needle cooler

1

Open looper cover

0

,

fill

the needle cooler

with

iilicone oil (available at extra cost) through

0

,

using the furnished oil feeder

2

Open fact? plate cover

@

.

remove plug

@

,

and

upp ply

s~llcone oil wlth the

011

feeder

I

Vot applicable to

MOG-25

16N)

3

lnflltrate sllicone oil also Into the

011

felt

~f

the

rndchlne

1s

~tdrted ~rnrned~ately after lubrlcat~ng the

nc.t.dle cooler

lower looper and the differential feed dog.

4-

Loading...

Loading...