hot water circuit (check pressure: max. 10 bar).

B Both deaerators open, the system is ventilated.

B Both deaerators close.

13

Water connections

B Check the final part of the exhaust pipe and the

wind protection and at the same time check the

free passage of the flue gas.

A manual deaerator 27.1 is mounted on the expansion

vessel and an automatic deaerator 27.2 is additionally

located on the pump .

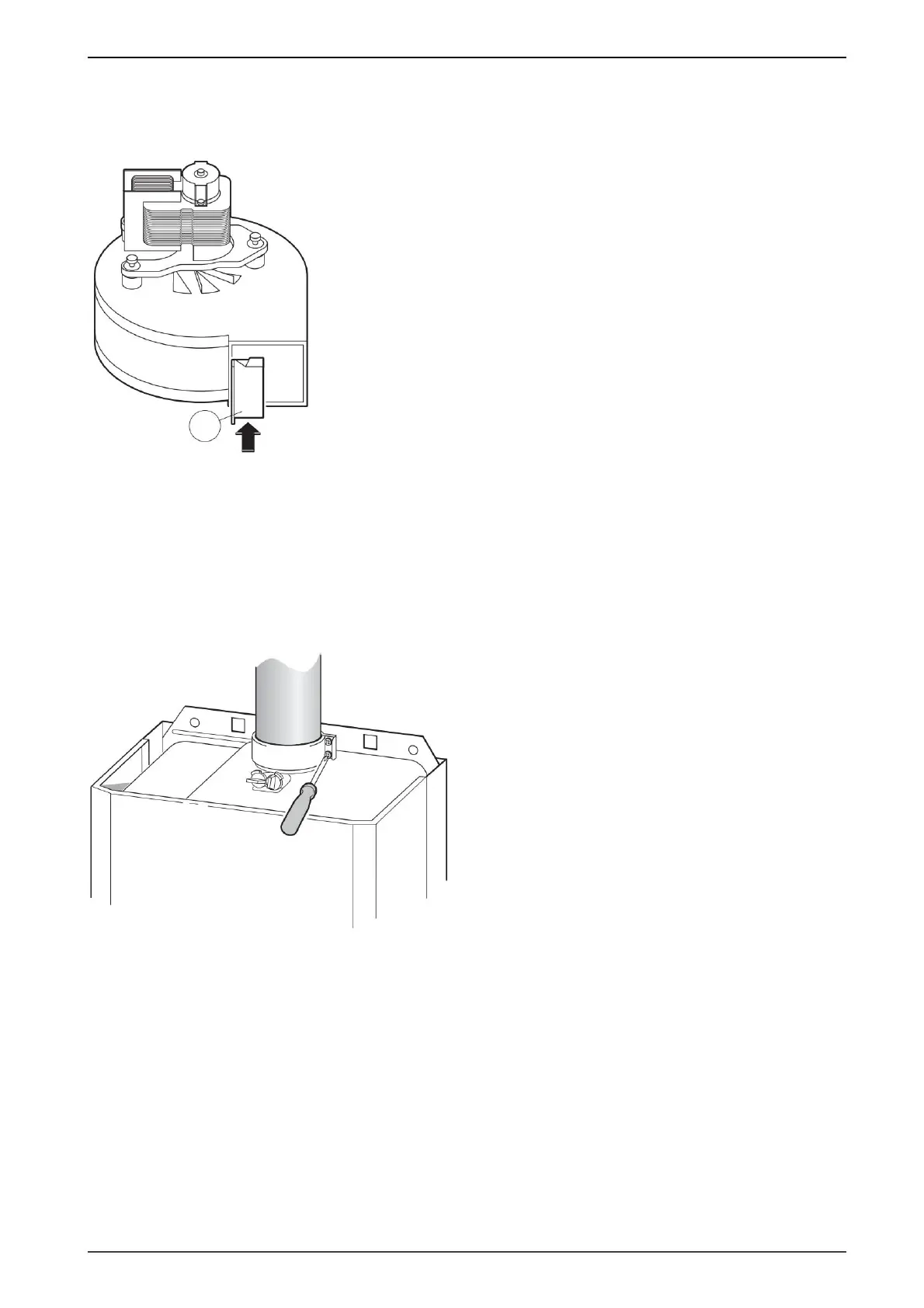

B Attach the flue gas attachment.

B Check all boiler joints for leaks.

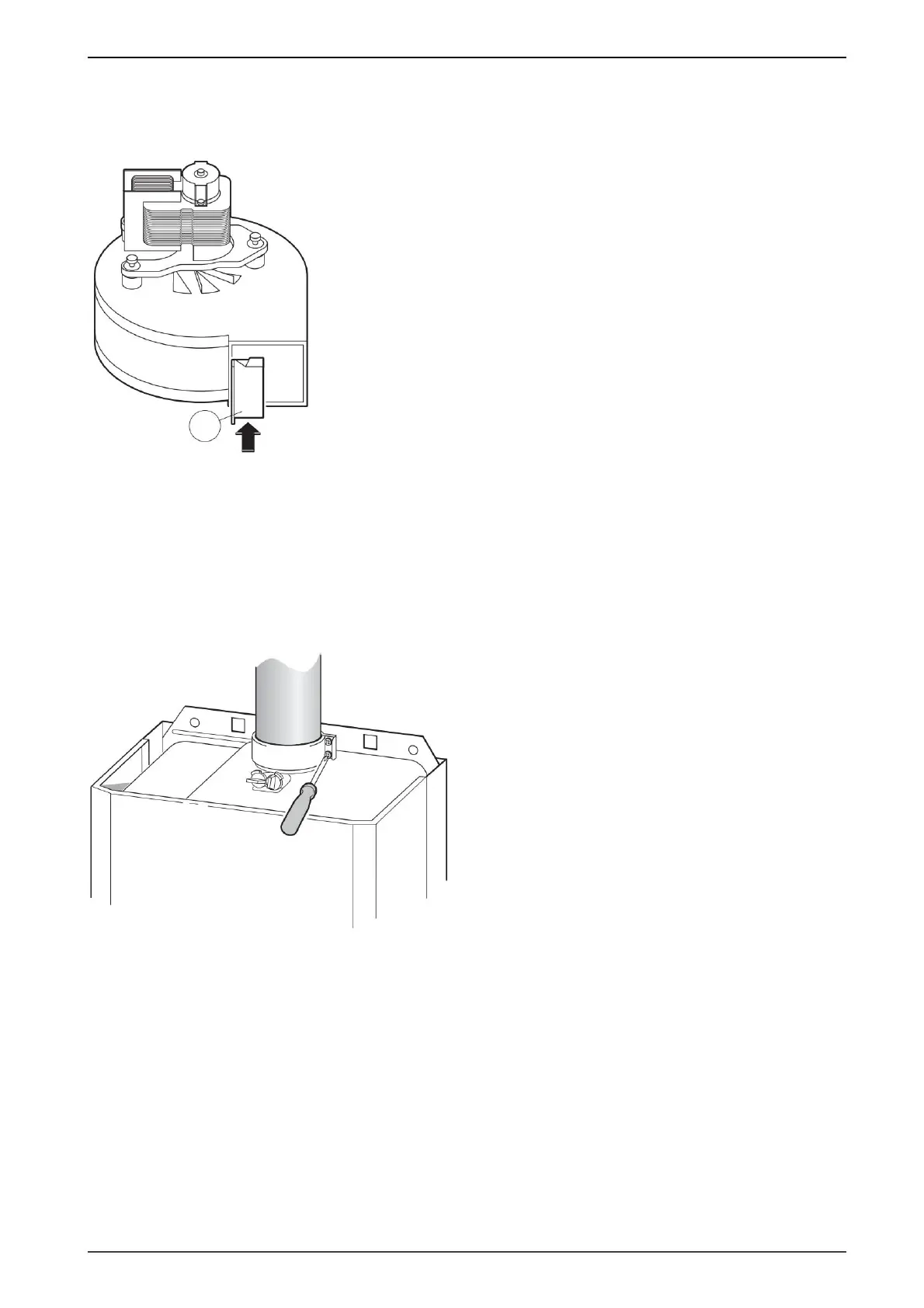

B Fit the corresponding reduction plate (1.7) to the

fan (226).

B Tighten the combustion chamber cover with the

screws.

Fig. 8

B Close the gas valve to protect the gas valve from

damage due to overpressure (maximum pressure

150 mbar).

B Depressurization is performed.

B Ventilate the appliance with the deaerator

B Refill the heating system to a pressure of 1 to

2 bar.

B Flow valves open and

B Open the cold water tap and fill

B Fill the heating system to a pressure of 1 to 2 bar.

B The flue gas accessory is provided.

Fig. 9

B Mount the housing and secure it with screws.

Ventilation of the heating system

Flue gas evacuation

B Check the gas system.

manual.

Installing

Gas pipeline

B Install the fan (226) in the boiler.

return the connection plate and fill the heating

system.

1.7

4873-30.1J

6 720 610 828 RO (02.01)

3.6 Checking the connections

Machine Translated by Google

Loading...

Loading...