OPERATOR’S MANUAL

9

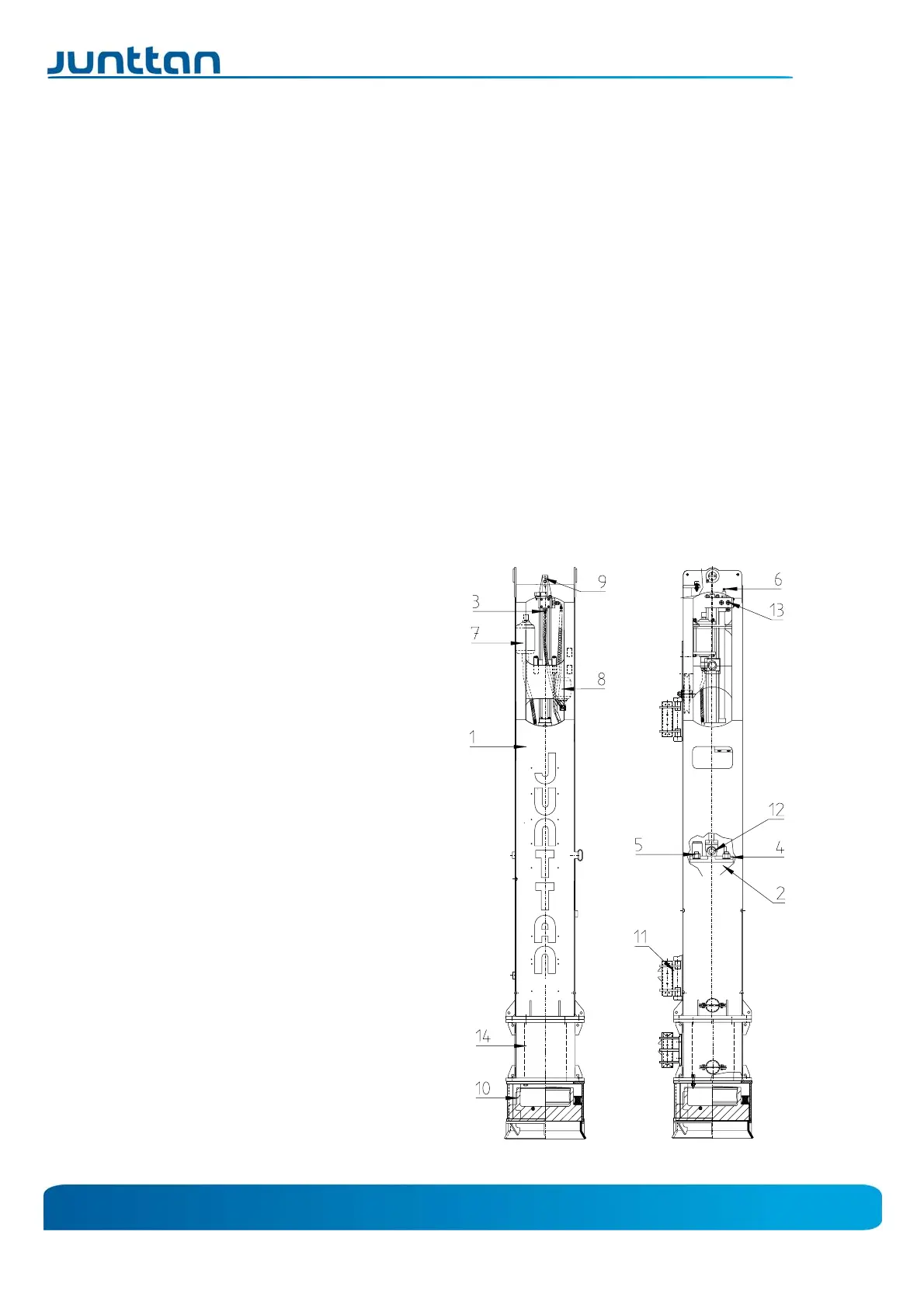

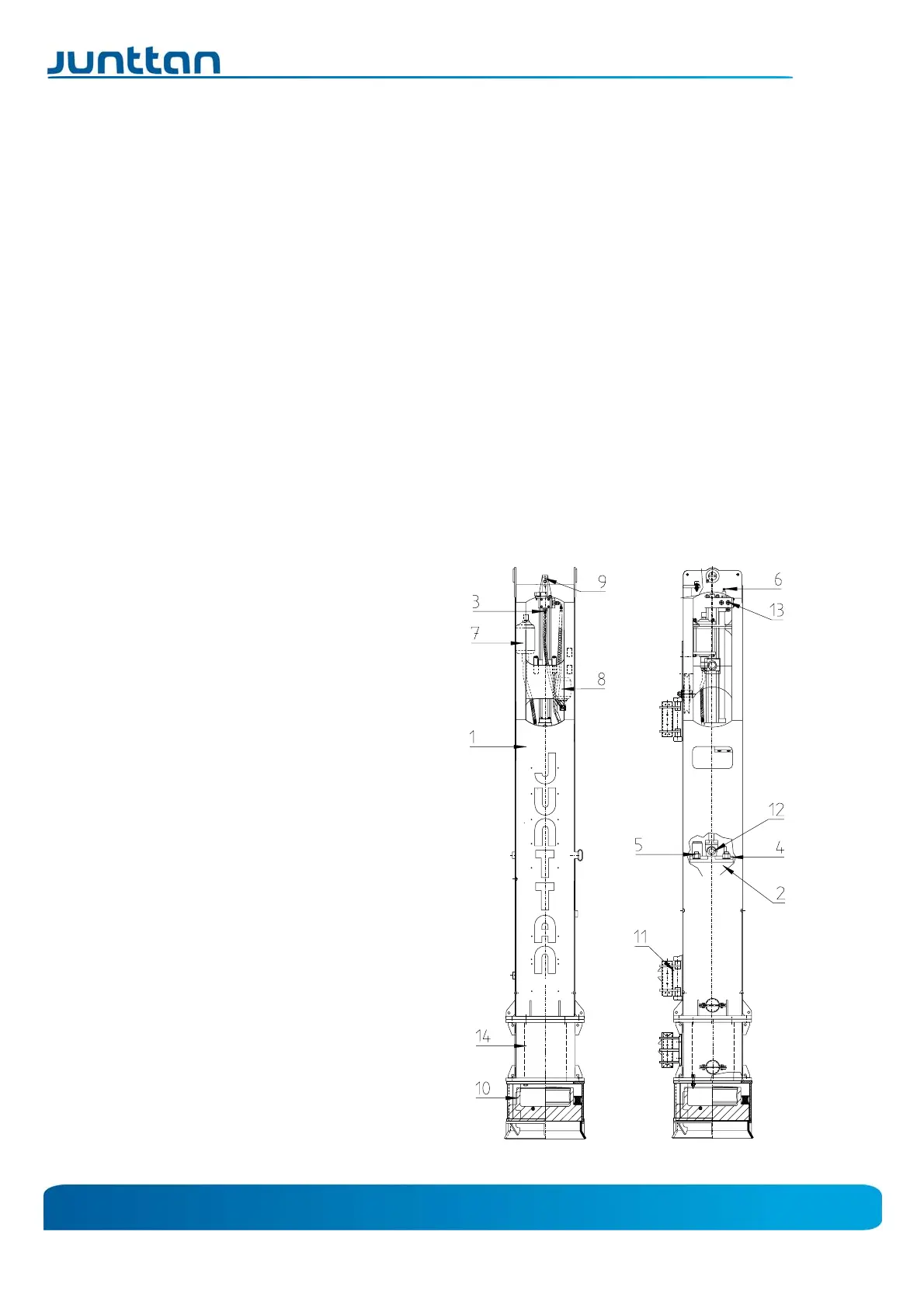

3. TECHNICAL DESCRIPTION JUNTTAN HAMMER

JUNTTAN hammer is a hydraulically-powered drop hammer for impact driving.

The cage frame houses the components of the hammer. There are bolted wear

pads on each corner of the ram block which slide along inside the frame

uprights. There is a hole inside the ram block. The ram block is bolted together

with a top plate. There is a rubber plate between the top plate and the ram block

to reduce the effect of the return stress wave during driving. A shaft connects

the top plate to the piston rod of the lifting cylinder through the lifting eye. The

spool valve which controls the lifting cylinder is built into the top end of the

cylinder. The spool valve is operated by a solenoid pilot valve. The position of

the piston rod is sensed with an inductive proximity switch. The lift buffer on the

top plate limits the stroke of the lifting ram during lift. For pile driving the

hammer is placed on the top of the pile. The hammer frame goes down until the

drive cap inside the drive cap housing moves against the rebound ring. In that

position the drive cap is at the end of its stroke and the ram block rests on

cushion.

The main components of the hammer are:

1. frame

2. modular ram block

3. lifting cylinder

4. top plate

5. ram block bolts

6. solenoid valve

7. hydraulic accumulator on the

pressure side for storing energy

8. hydraulic accumulator on the return

side to even pressure surges

9. proximity switch

10. drive cap housing incl. drive cap,

cushion and rebound ring

11. leader guides

12. ram block lifting eye

13. spool valve

14. frame extension

Loading...

Loading...