4.1. Checking upon receipt

• When the goods are delivered, make sure that all parts listed on

the delivery note are in perfect condition and have suffered no damage

during shipping.

• Make sure the vacuum pump has its identification plate affixed on

the front cover. Pumps without such identification are to be considered

anonymous and potentially dangerous: in such an event, they must not

be used, otherwise the manufacturer will be deemed free from any

liability whatsoever.

4.2. Storing in the warehouse

• If the pump will not be installed inside a short time after delivery:

− Remove the guards from the ports and spray a film of protective oil

over the inner surfaces of the body, rotors and sides. Then attach

again the guards;

− Store in a closed and dry place. Renew the preserving oil

periodically.

• To temporarily store a used pump, follow the instructions below:

− Thoroughly clean the pump.

− Equip the pump with suitable anti-corrosion protection.

4.3. Handling and installation

• Before each movement, verify that the lifting equipment has a

suitable capacity (check the weight of the decompressor, possibly

showed in this manual, in the paragraph 2.1).

• Do not lift the packaging or the machine when moving more than

50 cm from the ground. Proceed with the final lifting only near the

installation point.

• Harness the machine with suitable straps / chains near the main

body, paying attention to the position of the mass centre of gravity to

ensure the load stability.

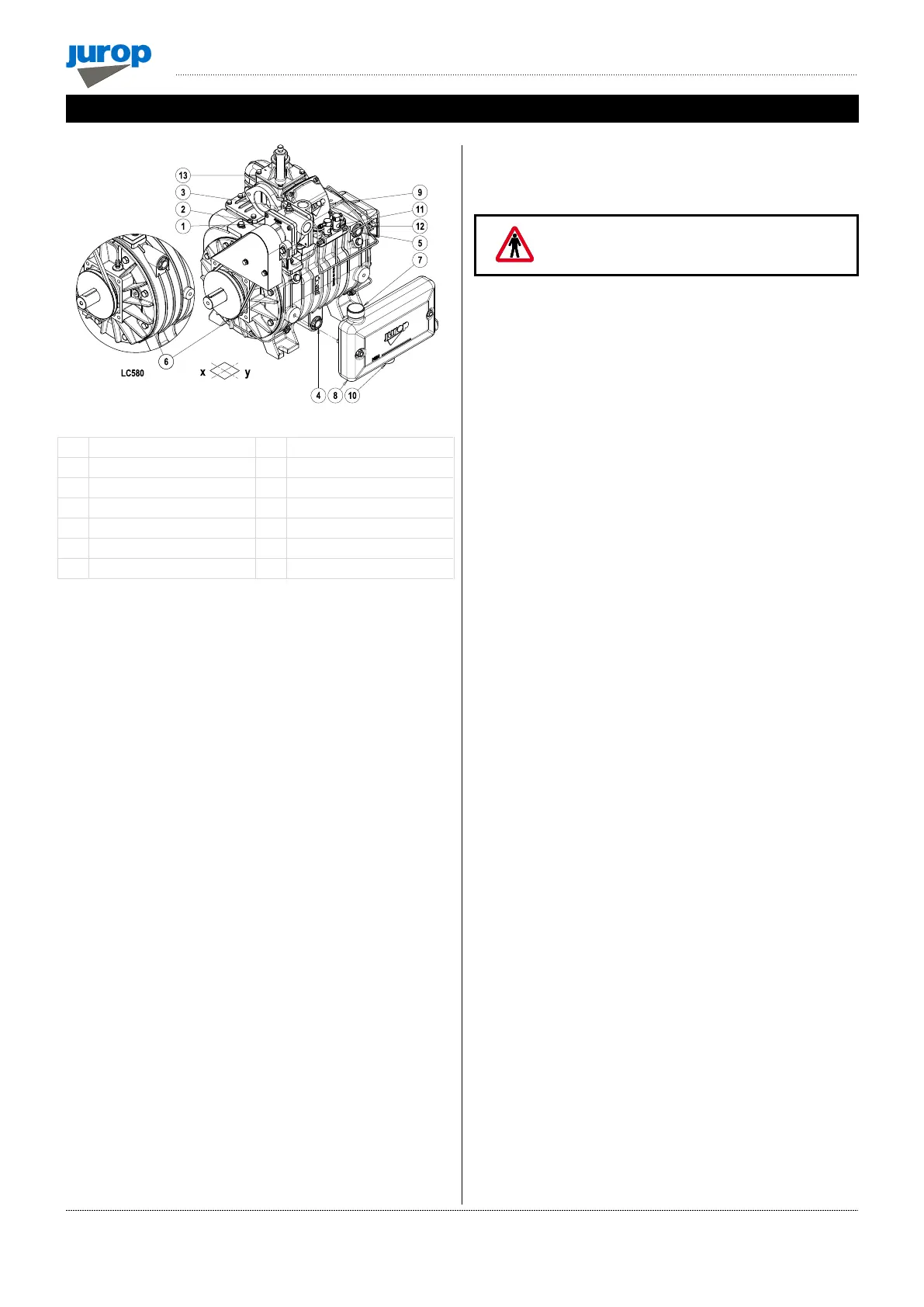

4.4. Mounting

• The pump must be assembled for an easy access for maintenance

operations and secured rigidly to a frame or levelled base (max. 3°

slant to the horizontal plane. See Fig. 4.1). The base must be such as

to avoid vibrations, bending or deformation.

• Where possible, we recommend the use of vibration dampers

between the support points of the machine and the base housing it.

• Leave enough space around the pump to allow the free circulation

of air for cooling; avoid exposure to dirt and debris.

• Prepare the necessary space for an easy access to the lubrication

check-points (tank level and gear box, oilers) and to the oil tank filling

port, the four-way manifold handle, and the vane wear inspection ports.

• Provide for suitable manoeuvring spaces of the inverter lever. The

control lever has two possible switching positions well defined by the

latches and numbers reported on the fusion. It is directly connected to

the internal diverter tang of the inverter, making it very intuitive: 90° of

the lever switching corresponds to 90° of the inverter switching.

• Based on the functionality of the system which will house the

decompressor, the designer of the end machine, must:

− Properly signal the functionality of the inverter according to the

position of the manual operating lever or of the pneumatic actuator

or of the hydraulic one.

− Install suitable pressure and / or vacuum restrainer valves near the

inlet and outlet points of the machine.

• In case of LC with hydraulic motor, provide the necessary space to

disassemble the motor itself and proceed with joint lubrication.

• In the event that the decompressor is electrically isolated, connect

it to the ground or make it equipotential with the housing machine.

Check that the paint does not prevent its passage.

• The machine expels gas during delivery at temperatures that can

reach the maximum permitted values for operation, with its lubricating

oil in suspension. Oil consumption is stated in paragraph 2.3, the

quantity of consumed oil corresponds to the quantity of oil emitted at

delivery.

• The installer will have to provide an appropriate delivery oil

separator (such as the JUROP cyclone silencer-oil separator supplied

on request) and/or direct the flow to the drain in an area that is not at

risk.

• The belt transmission guard of the coolant recirculation pump

supplied by Jurop is partial and must be completed/integrated with the

guard of the main transmission provided by the installer. If the

transmissions are accessible by the operator, protect them with a fixed

or interlocked guard and signal them with appropriate pictograms.

Loading...

Loading...