l

Ka

lmar Industries

DCD90·180

The DCD90-180 w ith a lift

cap

acity

of

9-

18 to

nn

es

is the n

ew

genera

ti

on

of

fo

rklift t

ru

cks in

th

e medium segm

en

t

of

Kalmar's c

ompr

ehensive range

of

4-

90

to

n t

ru

cks - a

we

ll prov

en

range

of

tru

cks in

co

r

po

rating

th

e latest design

so

lutions for o

ptimum

pr

o

du

c

ti

vity and

overa

ll

eco

nom

y.

A

co

mpr

ehensi

ve

range of op tional

e

quipm

ent

pac

kages facilitat

es

ad

ap

t

a-

tion to special handling environme

nt

s

and

different typ es

of

goods.

Ty

pe d

es

ign

at

ion:

DCD100·

12

Co

unt

e

r_-b

alan

ce

tru

ck

Dk

sel eng ine

::"_J

I T

Generation

---

- -

Lift

capac

i

ty,

d

ec

ito

nn

es

Loa

d

ce

ntr

e, decime

tr

e

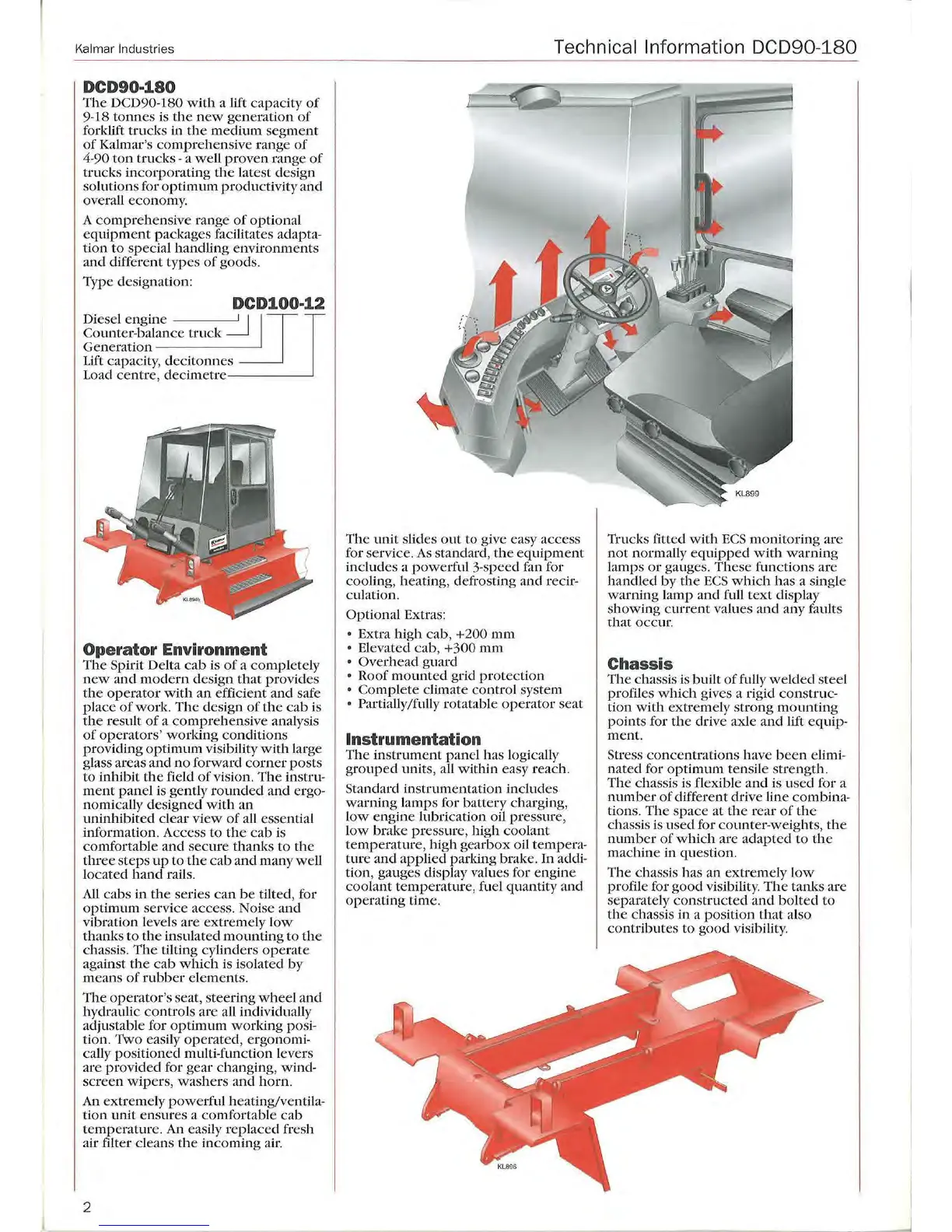

Op

er

a

tor

Environment

The S

pir

it Delta

ca

b is

of

a

co

mple

tely

n

ew

and mode

rn

d

es

ign

th

at provid

es

th

e op erator

with

an efficie

nt

a

nd

safe

place of work.

Th

e d

es

ign

of

the

ca

b is

th

e result

of

a

co

mpr

ehensi

ve

anal

ys

is

of

ope

rators '

wo

rking

co

nditions

providing o

ptimum

visibility w ith large

glass areas and n o forward

co

rn

er p osts

to inhibit

th

e field of vision .

Th

e ins

tru

-

ment

pa

nel is gently ro

und

ed and ergo-

no

mi

cally d

es

igned

with

an

uninhibited clear

vi

ew

of a

ll

essen

ti

al

inf

o

rm

a

ti

on. Access

to

the

ca

b is

co

mf

o

rt

able a

nd

sec

ur

e

th

anks to

th

e

thr

ee

steps

up

to th

e c

ab

and many

we

ll

located ha

nd

rails.

All

ca

bs in the

se

ri

es

ca

n be tilted, for

op

timum

ser

vi

ce

access. Noi

se

and

vibration l

ev

els are

ex

tr

eme ly l

ow

th

a

nk

s to

th

e insulated mounting to

th

e

chassis. The tilting cylinder s

ope

rate

against the

cab

whi

ch is isolated by

m

ea

ns

of

r ubb

er

elem

en

ts.

The

ope

rator's seat, st

ee

rin

g wheel and

hy

dr

aulic

co

ntr

ols are a

ll

individually

adjustable for

op

timum w orking

pos

i-

tion . Two

ea

sily op erated , erg

on

omi-

cally p ositioned multi

-f

unc

ti

on l

eve

rs

are p rovid

ed

fo

r gear changin

g,

wind-

sc

r

ee

n wipers, washers a

nd

ho

rn

.

An

ex

tr

emely

powe

rful h

eat

in

g/ve

ntila-

tion unit ens

ur

es a

co

m

fo

rt

able

ca

b

te

mp

erature. An easily r

ep

laced fre

sh

a

ir

filter cl

ea

ns the in

co

min

g a

ir.

2

Technical Information DCD90-

180

Th

e unit sli

des

out to give easy access

for

se

rvi

ce

.

As

standard, the equipment

includ

es

a p

owe

rful

3-s

p

ee

d fan for

coo

lin

g,

h

eat

ing, defrosting

an

d recir-

culation.

O

pti

onal

Ex

tra

s:

•

Ex

tr

a high

cab

, +200

mm

• Elevated

ca

b, +300

mm

• Ove

rh

ea

d guard

• Roof mo

un

ted grid p rot

ec

tio n

• Co

mpl

ete

climate co

ntr

ol system

• Pa

rt

ia

ll

y

/f

ully rotatable

oper

ator se

at

Ins

trum

en

ta

tion

Th

e in

st

rum

e

nt

pa

nel has logically

grou

pe

d units, a

ll

w ithin easy reach.

Sta

nd

ard ins

trum

e

nt

ation includes

wa

rnin

g la

mp

s for batte ry chargin

g,

l

ow

eng ine lubrication o

il

pressm e,

l

ow

br

ake

pr

ess

ur

e, high

coo

lant

te m

pe

rature, high gearb

ox

oil te mpera-

tur

e a

nd

applied p arking

br

ake.

In

addi-

tion , gau

ge

s display

va

lu

es

fo

r engine

coo

la

nt

tem

pe

rature , fuel quantity a

nd

op erating time.

Trucks fitted w ith

ECS

mo ni

to

rin

g are

not normally e

quipp

ed with w a

rnin

g

la

mp

s o r gauges. Th

ese

f

un

ct

ions are

handled by the

ECS

w hich has a s

in

gle

war

ning la

mp

a

nd

full t

ex

t display

sh

ow

ing current valu

es

a

nd

any faults

that

occ

ur.

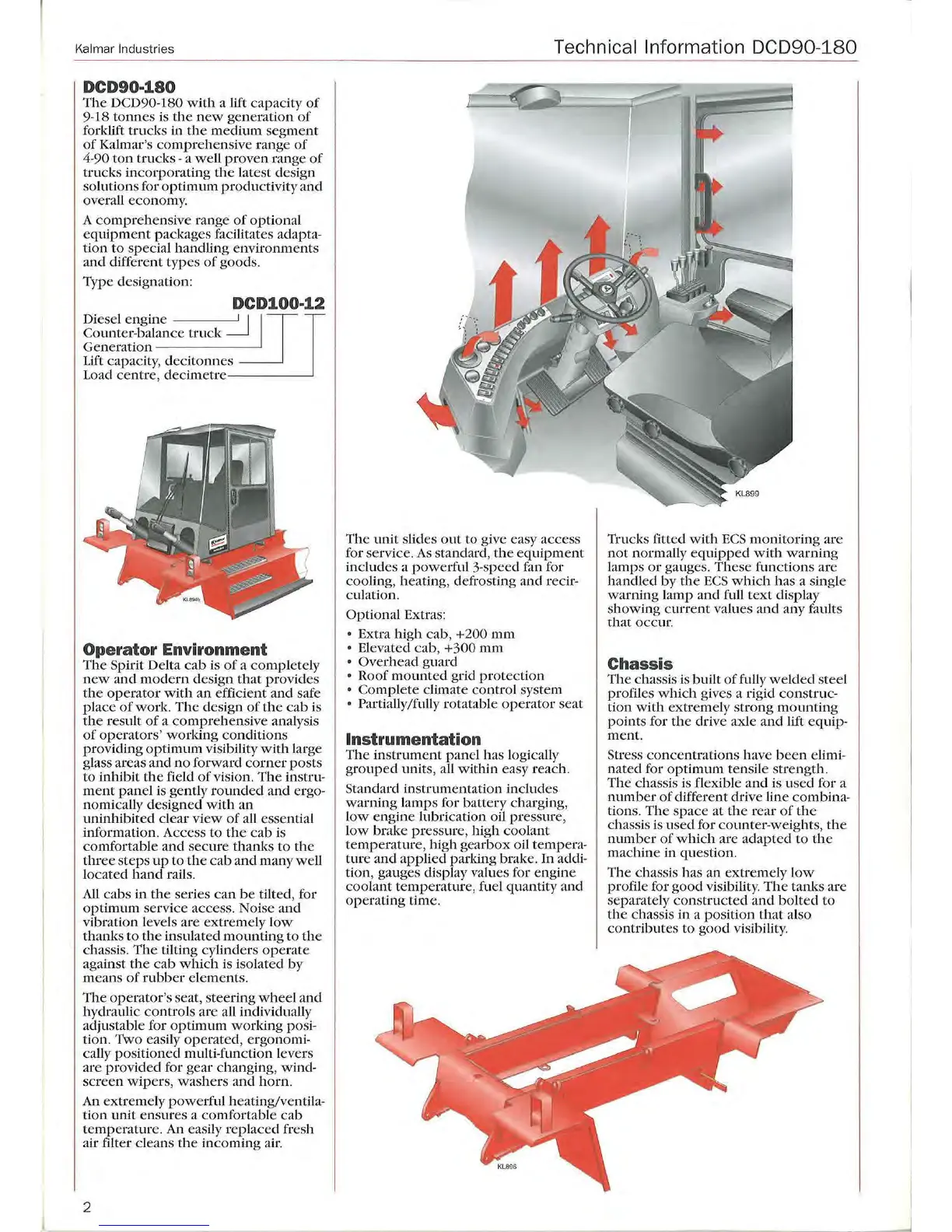

Chassis

The chassis is built

of

fully welded ste

el

p ro

fil

es w hich gives a rigid

co

n

str

u

c-

tion w

ith

ex

tr

emely s

tr

ong mounting

po

int

s for

th

e drive

ax

le a

nd

lift equip-

ment.

S

tr

ess

co

n

ce

ntrations have b

ee

n elimi-

Jut

ed for o

ptimum

tens

il

e

st

reng

th

.

The chassis is flexible and is used

fo

r a

numb

er

of

different drive

li

ne

co

mb

ina-

tions. The sp ace at the re

ar

of

th

e

c

ha

ssis is used for

co

unt

er-weig

ht

s,

th

e

numb

er

of

w hich are ada

pt

ed

to th

e

m

ac

hine in qu

es

tion.

The chassis

ha

s an

ext

remely l

ow

pr

o

fil

e for good vi

si

bilit

y.

The ta

nk

s are

sepa

ra

te

ly

co

n

str

ucted and bol

te

d to

th

e chassis in a p osition that al

so

co

ntribu

tes to good visibilit

y.

Loading...

Loading...