Technical Information DCD90-180

Electrical System

The

el

ect

rical system is logically struc-

tured, easily serviced a

nd

comp

letely

coordi

nat

ed

wit

h the

other

trucks

in

the

Kalmar range.

The

system

is

suppli

ed

by

two

12V batteries

connected

in

ser

ies charged by

an

a

lt

er-

nator,

with

re

lated electronics for recti-

ficati

on

and

current

stab

ilization.

The

system

provides

high

power

levels

even

at

low

engine revs. Th e electrical

fuses, relays and

connectors

are

l

ocated

in

an

eas

il

y accessible

position

withi

n a

centra

l electrical unit inside

the

cab,

behind

the

operator

's seat.

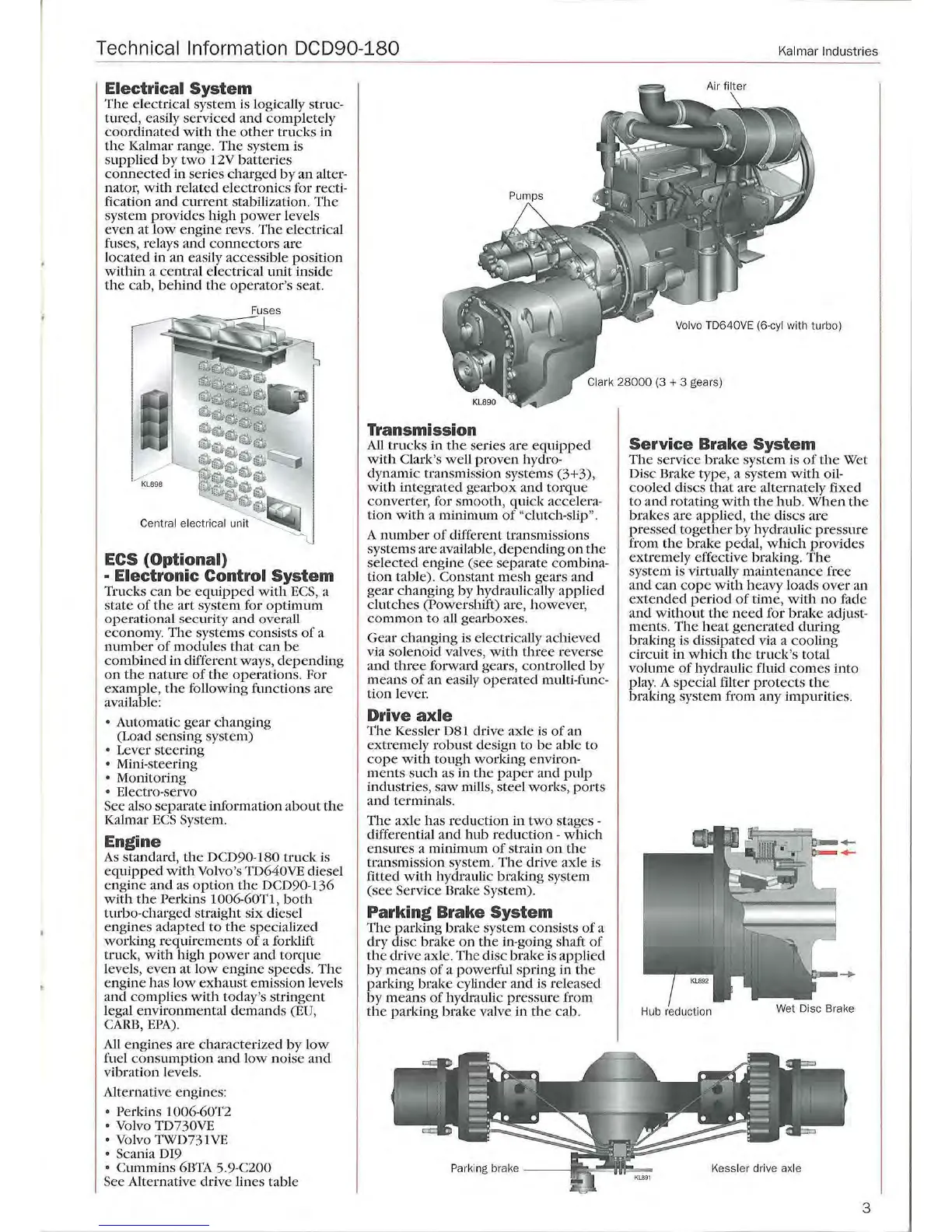

KL898

Central electrical unit

ECS (Optional)

· Electronic Control

System

Trucks can

be

equ

ipp

ed

w

ith

ECS,

a

sta

te

of

the

art

system for

optimum

operational security

and

overa

ll

eco

nomy.

The

systems consists

of

a

numb

er

of

modules that

can

be

comb

in

ed

in different ways,

depending

on

the

nature

of

the

operations.

Fo

r

examp

le,

the

foll

owing

functions are

ava

il

able:

• Automatic

gear

changing

(Load sensing system)

• Lever

steer

in

g

• Mini-steering

• Monitoring

• El

ec

tr

o-se

rv

o

See also

sepa

r

ate

in

form

at

i

on

about

the

Kalmar

ECS

System.

Engine

As

standard,

the

DCD90-180

truck

is

eq

ui

pped

with

Volvo 's TD640VE diesel

eng

in

e and as

opt

i

on

the

DCD90-136

with

the

Perkins 1006-60T1,

both

turbo-charged straig

ht

six diesel

eng

in

es

adapted

to

the

specia

li

zed

working requirements

of

a forkl ift

truck

, wi

th

high

power

and

torque

level

s,

even

at l

ow

engine

speeds

.

The

eng

ine has l

ow

exha

u

st

emission l

eve

ls

and

comp

lies

wit

h today's stringent

legal

env

ir

o

nment

al

demands

(EU,

CARB,

EPA).

Al

l

eng

in

es

are characterized by l

ow

fuel

co

nsumpti

on

and l

ow

noise and

vibration levels.

Alternative engines:

• Perkins l 006-60T2

•

Volvo TD730VE

• Volvo TWD731VE

• Scania DI9

• C

ummin

s

6BTA

5.9-C200

See

Alternative drive lin

es

table

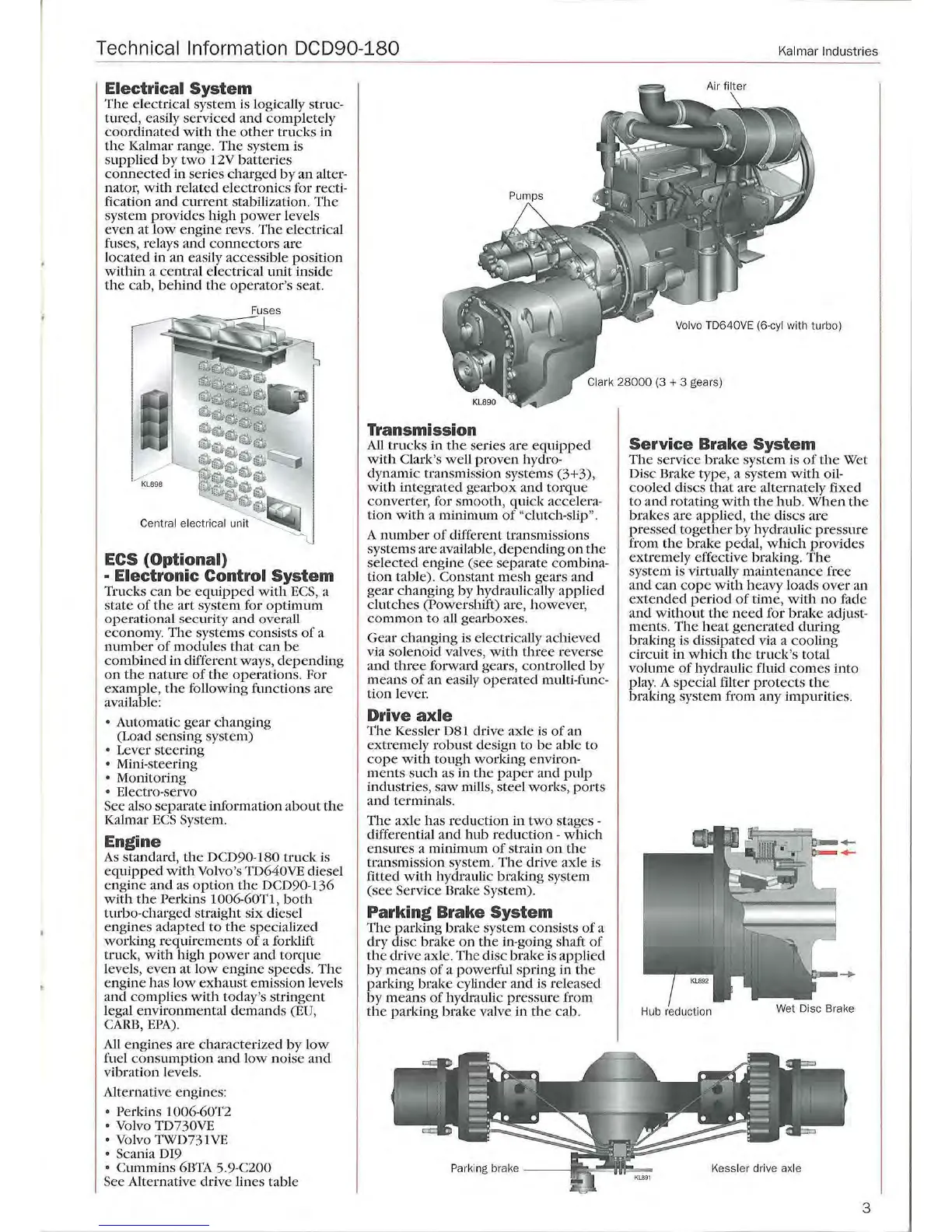

Transmission

Al

l t

ru

cks in

the

ser

i

es

are

equ

ip

ped

wit

h Clark's

we

ll

proven

hydro-

dynamic transmission systems

(3+3)

,

with integrated gea

rb

ox

and

torque

co

n

verter

, for

smooth

,

quick

acce

lera-

tion w

ith

a minimum

of

"clutch-slip".

A

number

of

different transmissi

ons

systems are available,

depending

on

the

sel

ected

engine

(see separate combin

a-

tion

table). Constant

mesh

gears and

gear

cha

nging by hydraulically

app

li

ed

clutches

(Powers

hift) are, h

owever

,

common

to all gearboxes.

Gear changing is el

ect

ri

ca

ll

y achieved

via sol

enoid

valves,

with

three

reverse

and

three

forward gears,

cont

ro

ll

ed

by

means

of

an

easily

ope

rated multi-func-

tion lever.

Drive

axle

The

Kessler

D81

drive axle is

of

an

extreme

ly robust design to

be

able to

cope

w

ith

tough

wo

rking environ-

ments

such

as

in

the

paper

and

pulp

indu

st

ries, saw mills,

stee

l

wo

rks,

ports

and

t

ermina

l

s.

The

axle has reduction in

two

stages -

diff

ere

ntial and

hub

reduction

-

which

ensures

a minimum

of

strain

on

the

transmission system.

The

drive axle is

fitted w

ith

hydraulic braking system

(see

Servi

ce

Brake System).

Parking Brake System

The

parking brake system consists

of

a

dry

disc

brake

on

the

in-going shaft

of

the

drive axle. The disc brake

is

applied

by

means

of

a powerful

sp

ring in

the

parking

brake

cylind

er

and

is released

by

means

of

hydraulic

pressure

from

the

parking brake valve

in

the

cab.

Kalmar Industries

Vo

l

vo

TD640VE (6-cyl with turbo)

Service Brake System

The

service brake system

is

of

the

Wet

Disc Brake type, a system w

ith

o

il

-

coo

led discs

that

are a

lt

ernate

ly

fixed

to

and rotating

with

the

hub.

When

the

brakes

are

app

li.

ed

,

the

discs are

pressed

together

by

hydraulic

pressure

from

the

brake pedal,

whic

h

provides

extremely effective braking.

The

system is v

irtu

a

ll

y

maintenance

free

and

can

cope

wit

h heavy l

oads

over

an

extended

period

of

time,

with

no fade

and

w i

thout

the

need

for

brake

adjust-

ments. The

heat

generated

durin

g

braking is dissipated via a

coo

ling

circ

uit

in w hi

ch

the

truck

's total

volume

of

hydraulic fluid

comes

int

o

play. A

spec

ial filter

protects

the

braking system from any impmities.

Hub reduction

Kessler drive

axle

3

Loading...

Loading...