L

Kalmar Industries

Steering System

The steering system is

co

mpl

etely

hydraulic

and

is

ted

from hydraulic

pump

1 (see

th

e hydraulic system

diagram), via a priority valve.

Wh

en the

st

ee

ring

whee

l is

turned

,

th

e st

ee

ring

v

al

ve transmits a load signal to the

priority val

ve

which

ensures

that

the

st

ee

ring system always has sufficient

hydraulic

pr

ess

ur

e.

Th

e steering

ax

le

is

an

extremely

robust

co

nstruction with double-ac

ti

on

cylinder.

Th

e p endulum suspension

of

the

ax

le

over powerful,

spherica

l

rubber

bear

-

ings has a lo

ng

operative lif

espan

and

pro

vides good s

ho

ck-absorption .

The

minimal

numb

er of parts ensures

oper

-

ational reliability, a minimum

of

se

rvice

point

s and easy ma

int

enance. The

st

ee

ring

geometry

allows large

whe

el

displa

ce

me

nt

and

thereb

y,

a tig

ht

tmning

circle.

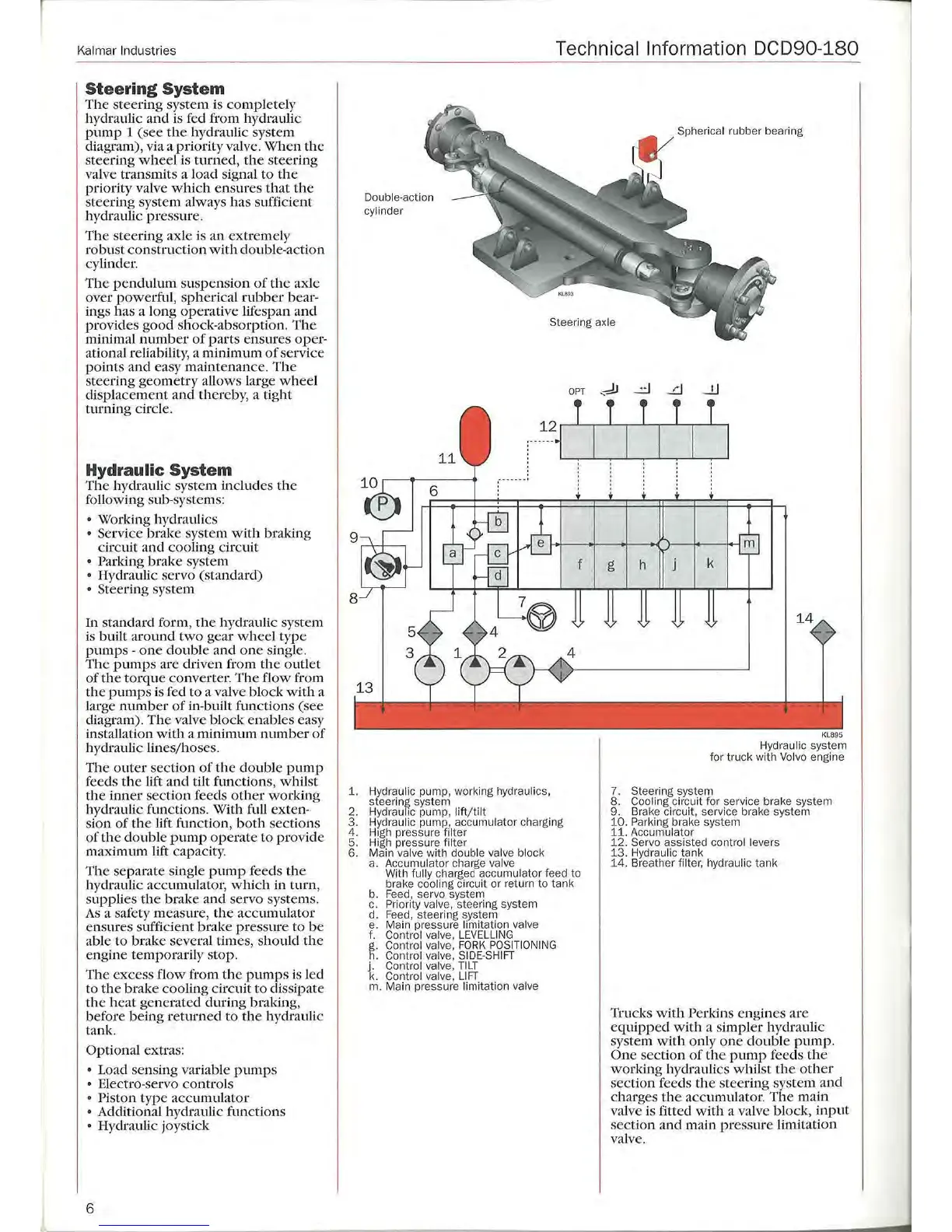

Hydraulic System

Th

e hydraulic system includ

es

th

e

following sub-systems:

• Working hydrauli

cs

• Service bral{e system

with

br

aking

circuit and cooling circuit

• Parking brake sys

tem

• Hydraulic servo (standard)

• St

ee

rin

g system

In standard form,

the

hydraulic system

is built a

round

two

gear

wheel

type

pump

s -

one

double and

one

single.

Th

e

pumps

are driven from

th

e o utlet

of

the

to

rque

converter.

The

fl

ow

from

th

e

pumps

is

feel

to a

va

lve block

with

a

large

number

of

in-built fun

ct

ions (see

diagram). The valve block enabl

es

easy

installation

with

a minimum

number

of

hydraulic lin

es/

ho

ses.

The

oute

r section

of

th

e

do

uble

pump

feeds

the

lift

and

tilt functions,

wh

il

st

the

inner

sect

i

on

feeds

other

working

hydraulic function

s.

With fu

ll

exten-

sion

of

th

e lift function, both

sec

tions

of

the

double

pump

operate

to

pr

ovide

maximum

lift

ca

pa

city.

The

separate single

pump

f

ee

ds

the

hydraulic accumulator,

which

in

turn

,

suppli

es

th

e brake

and

servo systems.

As

a safety meas

ur

e,

the

accumu

lator

ensures suffici

ent

brake pressure

to

be

able to

br

ake several times, should

th

e

engine temporarily stop.

Th

e excess

flow

from

the

pump

s is l

ed

to

th

e brake cooling circ uit to dissipate

the he

at

generated during braking,

befo

re

being re

turned

to

the

hydraulic

tank.

Optional extras:

• Load sensing variable

pump

s

• Electro-servo

co

ntrols

• Piston

type

accumul

ator

• Additional hydraulic functions

• Hydraulic joystick

6

Technical Information DCD90-180

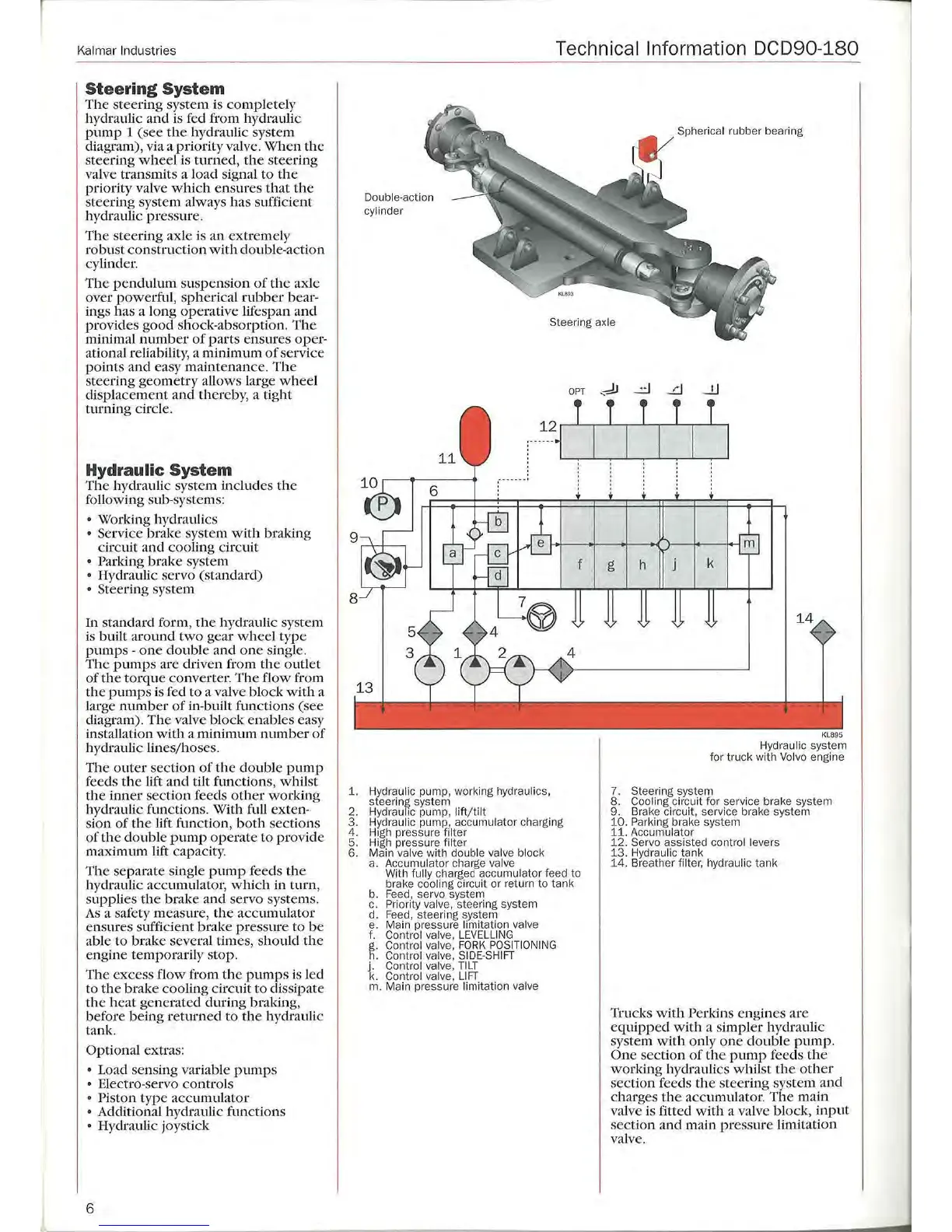

Double-action

cyl

in

de

r

Spherical

rubber bearing

Steering

axle

1. Hydraulic

pu

mp, working

hyd

raulics,

steering system

2.

H

yd

raulic pump,

lift/t

ilt

3. Hydraulic pump, accumulator charging

4.

H1

gh

pressure filter

5. High press

ur

e fil

te

r

6. Main valve wi

th

double

va

l

ve

block

a.

Accumulator

cha

r

ge

valve

With fully charged accumulator feed to

brake

cooling circuit or return to tank

b.

Feed,

servo system

c.

Priority valve, steering syst

em

d.

Feed,

steering system

e.

Main pressure limitation

va

l

ve

f. Contr

ol

valve,

LEVELLING

g .. Contr

ol

valve,

FORK

POSITIONING

h

Co

ntr

ol

valve,

SIDE

-

SHIFT

j.

Control valve,

TILT

k. Contr

ol

valve,

Ll

FT

m. Main pressure limitation valve

KL695

Hydra

ulic system

fo

r tru

ck

with

Vo

l

vo

engine

7. Steering system

8.

Cooling

ci

rc

uit for

se

rvi

ce

brake system

9. Brake

ci

rcuit, service brake system

10

.

Pa

rking brake system

11

. Accumulator

12.

Se

r

vo

assisted control levers

13.

Hyd

raulic tank

14.

Breather filter, hydraulic tank

Trucks

with

Perkins engines

are

equipped

with a simpl

er

hydr

aulic

system

with

on

ly

one

double

pump.

One

section

of

th

e

pump

feeds

the

working hydrauli

cs

whi

l

st

the

other

sect

ion

f

ee

ds

the

steer

ing system a

nd

charges

the

accumulator.

The

main

va

lve is fitted

with

a valve block,

input

section and main

pr

ess

ur

e limitation

va

lve.

--

Loading...

Loading...