-2-

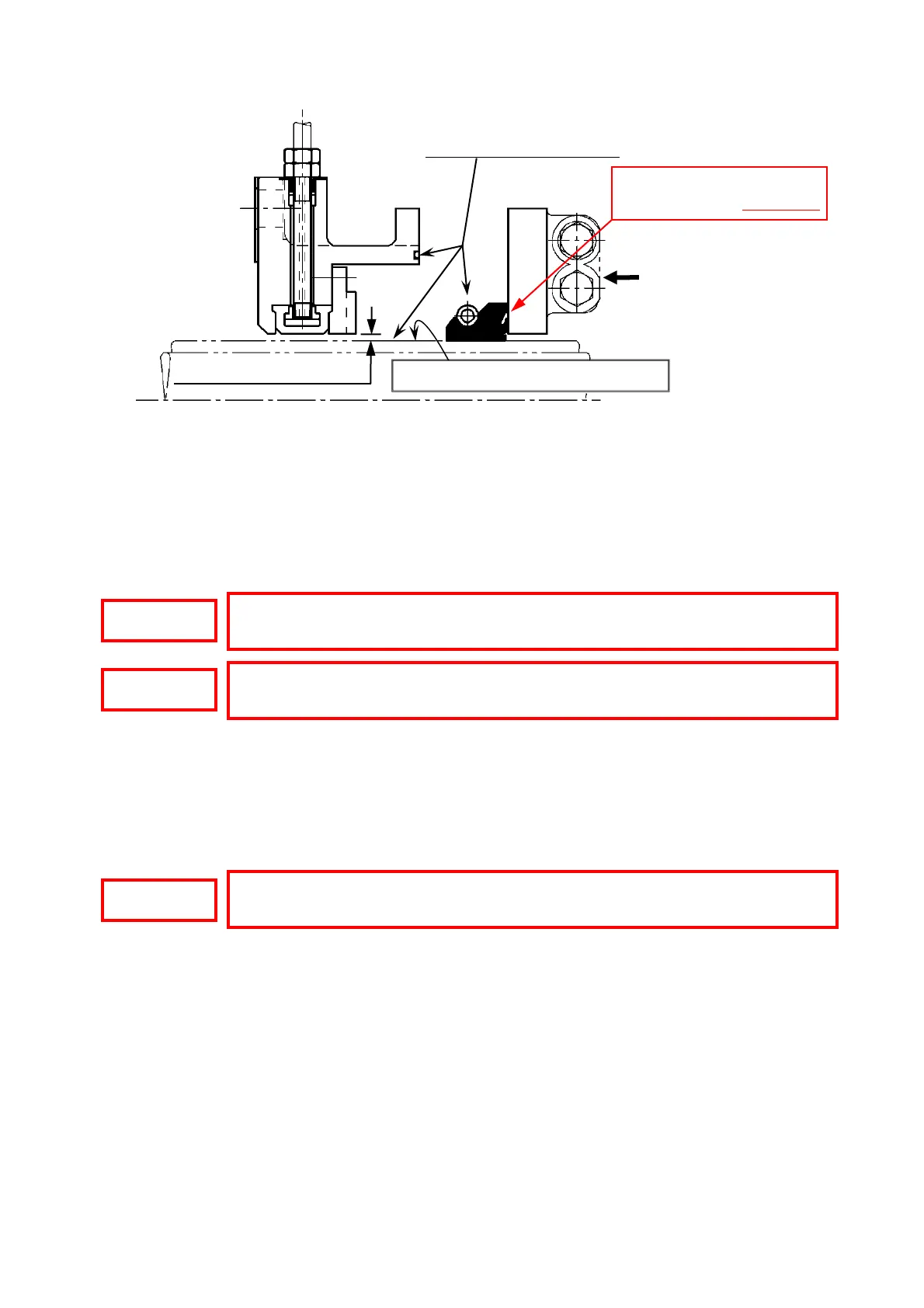

Fig.-1

[B] Piping

1 Piping for water supply

Confirm that the supply water pressure is the draft pressure plus 0.01~0.03 MPa

in close vicinity to the seal.

2 Piping for air supply

(1)The air piping from the 0.6~1.0MPa (reduced) air source should be provided with

an escape valve.

(2)Being careful not to twist the anchor pin when connecting or disconnecting tube

fitting for air pipe.

[C] Inspection

1 Before launching

Supply an air pressure of 0.3~0.6 MPa to the inflatable ring, and apply twice

as great a water pressure as the draft pressure from the water supply line to verify

that water is continuously no leaking from the seal ring, and that the air pressure

drop is within 10 % per hour.

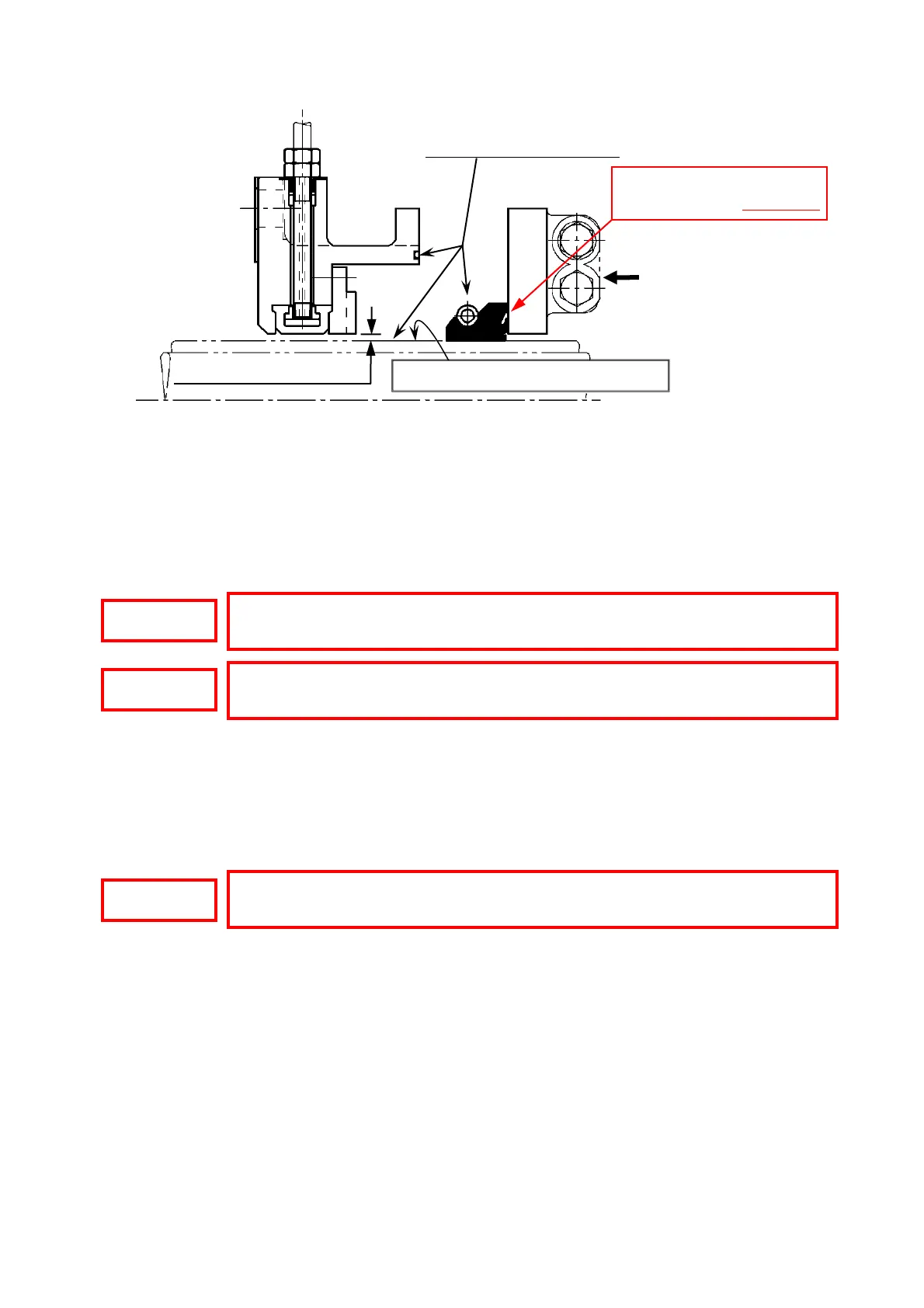

2 After launching

Check to see that water is continuously no leaking from the seal ring.

Stop the propeller shaft. Close all water supply line fully. Supply an air pressure

to the inflatable ring. Then open the plug ③ and check to verify that water is

continuously no leaking. (See Fig.-2)

Disconnect the air supply line normally in order to prevent a

inflatable ring from breaking.

BE CAREFUL OVER APPLYING GREASE.

Remove grease from the

sliding surface COMPLETELY

Apply a thin coat of grease

Must not too bend rubber hose.(In the case of rubber hose connection)

Supply water during rigging or long time anchorage for protecting

the inside of piping from marine organism growing.

Loading...

Loading...