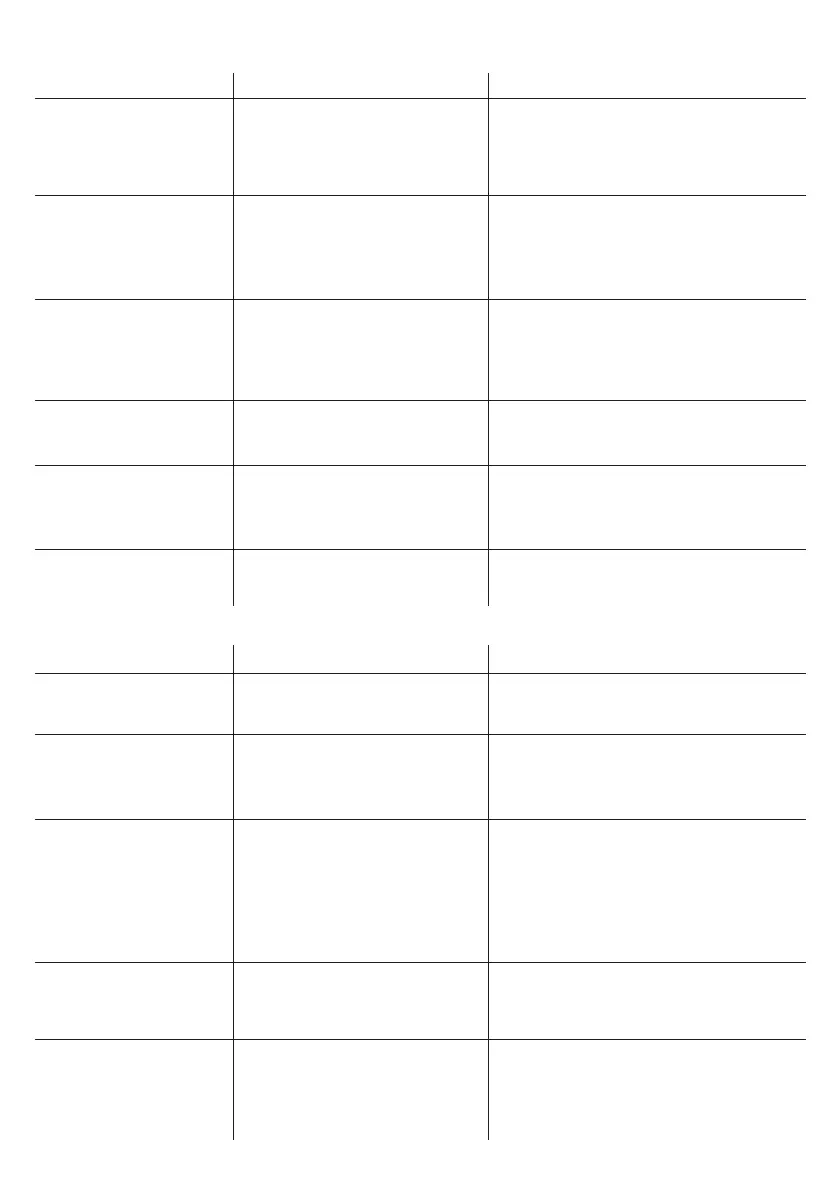

Motor component

Motor does not work

Motor protection

switch always turns

itself off

Motor heats up

Motor runs

very slowly

Motor vibrates

Motor makes very loud

running noises

- No current

- Cable defective

- Switches or motor defective

- Motor protection switch off

- Rotor or pole ring defective

- Blades blocked

- Motor protection switch

defective

- Air filters clogged

- Supply air covers clogged

- Shear blade tension too high

- Rotor or pole ring defective

- Carbon brush used up

- Rotor runs untrue

- Bearings are worn out

- Fan wheel broken

- Bearing defective

Check socket and fuse

* Have replaced by specialised workshop

* Have replaced by specialised workshop

Turn motor protection switch on

* Have replaced by specialised workshop

Repair blockage

* Have replaced by specialised workshop

Clean air filters

Clean or replace supply air covers

Tighten tension screw less. Replace the

blades, if they then don’t cut anymore

* Have replaced by specialised workshop

* Have replaced by specialised workshop

* Have replaced by specialised workshop

* Have replaced by specialised workshop

* Have replaced by specialised workshop

* Have replaced by specialised workshop

Cause Troubleshooting

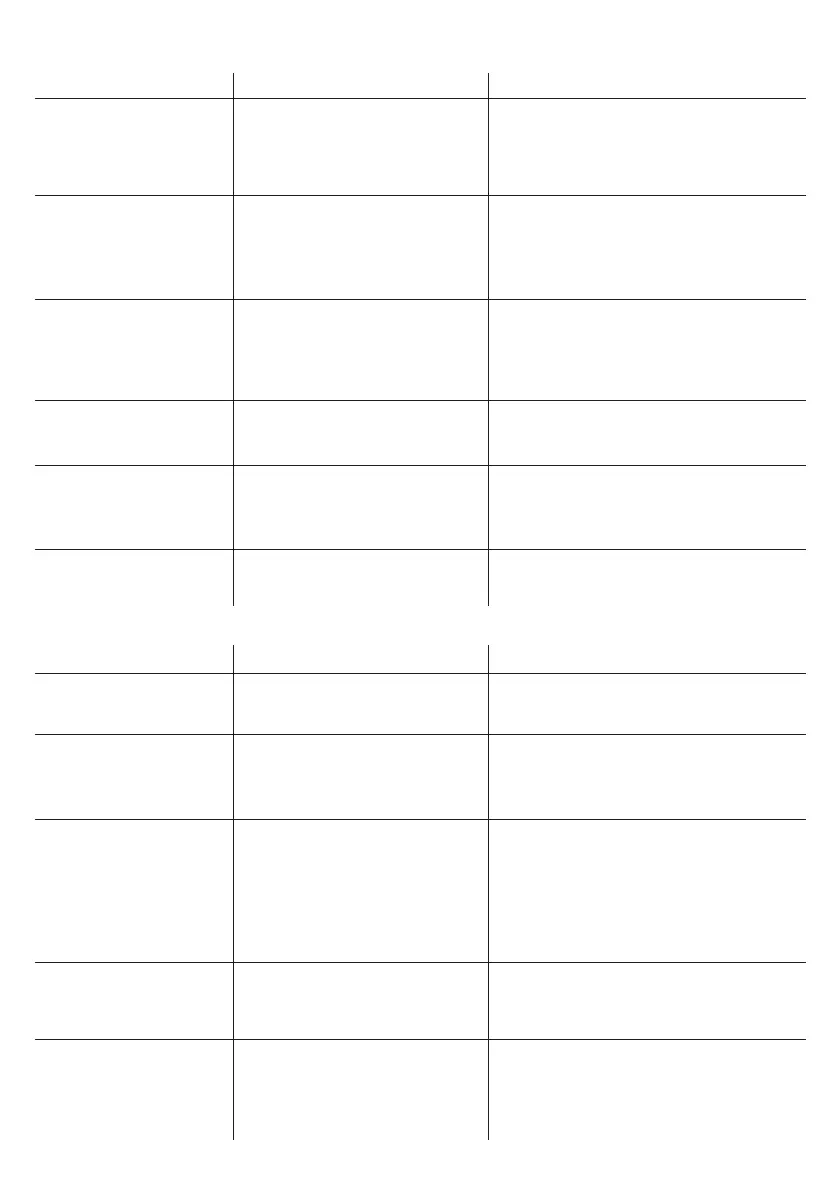

Clipper head

Upper plate does not

move

Upper plate does not

move over the entire

contact surface

Blades cut badly

Blades do not cut

Clipper head

gets very hot

- Transmission defective

- Eccentric worn

- Eccentric shaft defective

- Upper blade or lower blade are

blunt

- Blades haven’t been sharpened

well

- Shear blade tension too low

- Eccentric defective

- Transmission defective

- Clipper head worn out

- Shear blade tension too high

- Shear blade and/or eccentric

without lubricating film

* Have replaced by specialised workshop

* Have replaced by specialised workshop

* Have replaced by specialised workshop

* Have specialised workshop resharpen

blades

* Have specialised workshop resharpen

blades

Increase tension with tension screw

* Have replaced by specialised workshop

* Have replaced by specialised workshop

* Have replaced by specialised workshop

Reduce shear blade tension, poss.

resharpen blades and relubricate

with SAE 30 HD oil

Cause Troubleshooting

25

5.2 Malfunction list

C3_BA_19-27_Rind/Pferd_EN 23.07.2007 15:22 Uhr Seite 25

Loading...

Loading...