24

5. Repairs

5.1 Introduction

You can read up on troubleshooting measures on the next page. Only authorised technical personnel may carry out troubleshooting measu-

res marked with an *.

5.2 Malfunction lists

Contact an authorised service department to repair not listed malfunctions.

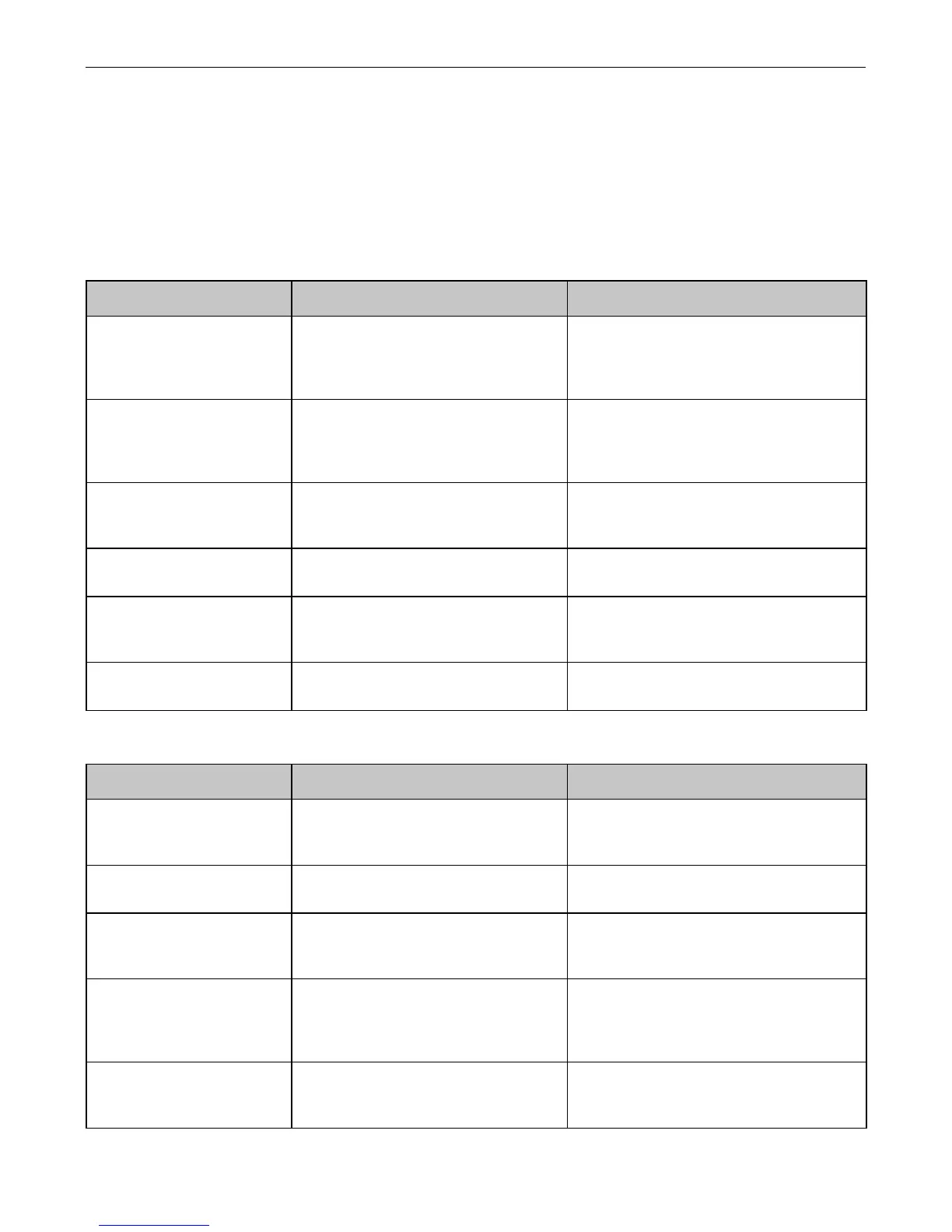

Motor component Cause Troubleshooting

Motor does not work - No current

- Cable defective

- Switches or motor defective

- Motor protection switch off

Check socket and fuse

* Have replaced by specialised workshop

* Have replaced by specialised workshop

Turn motor protection switch on

Motor protection switch always

turns itself off

- Rotor or pole ring defective

- Blades blocked

- Motor protection switch defective

- Air filters clogged

* Have replaced by specialised workshop

Repair blockage

* Have replaced by specialised workshop

Clean air filters

Motor heats up - Supply air covers clogged

- Shear blade tension too high

Clean or replace supply air covers

Tighten tension screw less. Replace the

blades, if they then don’t cut anymore

Motor runs very slowly - Rotor or pole ring defective

- Carbon brush used up

* Have replaced by specialised workshop

* Have replaced by specialised workshop

Motor vibrates - Rotor runs untrue

- Bearings are worn out

- Fan wheel broken

* Have replaced by specialised workshop

* Have replaced by specialised workshop

* Have replaced by specialised workshop

Motor makes very loud running

noises

- Bearing defective * Have replaced by specialised workshop

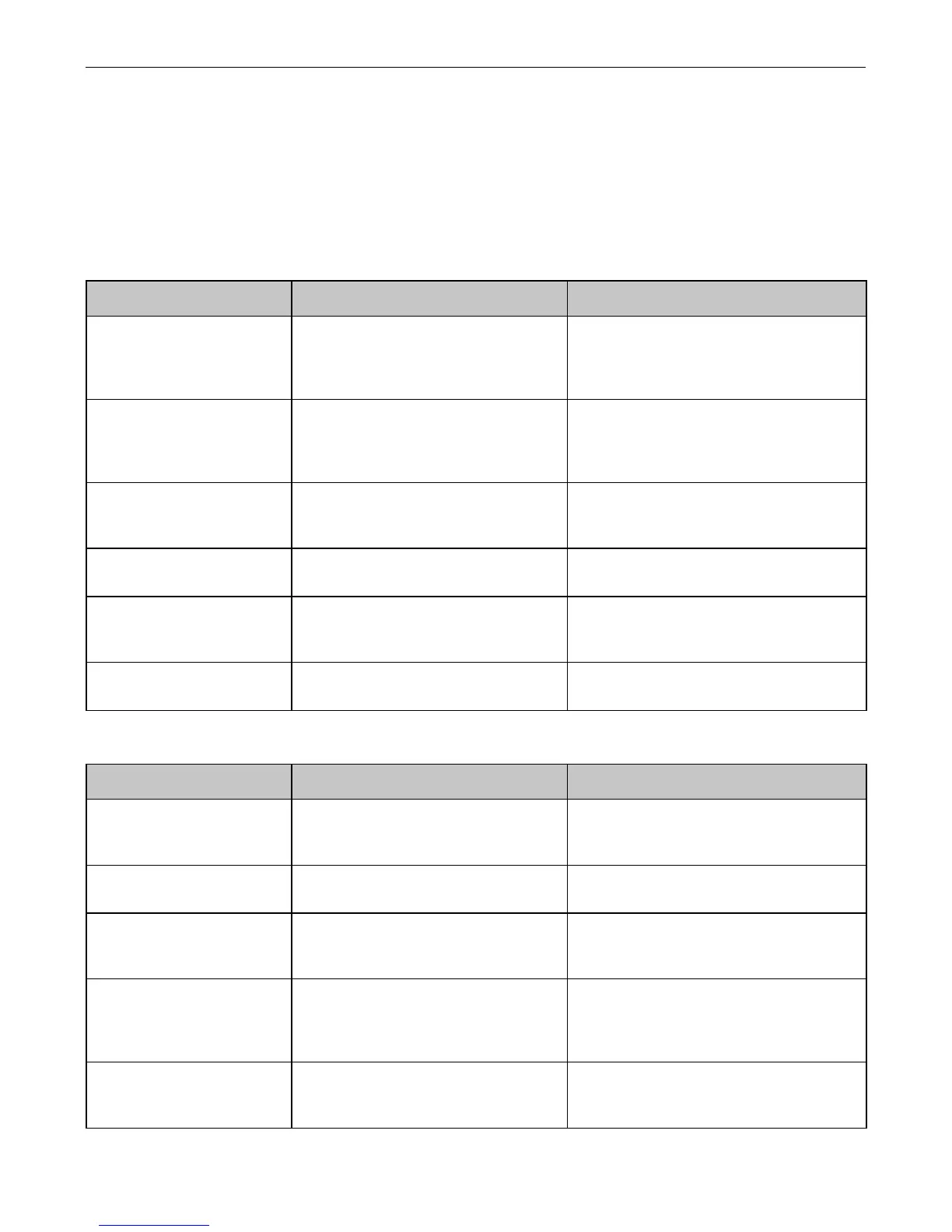

Clipper head Cause Troubleshooting

Upper plate does not move - Eccentric shaft defective

- Transmission defective

- Eccentric roller defective

*Have replaced by specialised workshop

Replace transmission

Replace eccentric roller & mounting bracket

Upper plate does not move over

the entire contact surface

- Eccentric shaft defective

- Eccentric roller defective

*Have replaced by specialised workshop

Replace eccentric roller & mounting bracket

Blades cut badly - Upper blade and/or lower blade are blunt

- Blades haven’t been sharpened well

- Shear blade tension too low

* Have specialised workshop resharpen blades

* Have specialised workshop resharpen blades

Increase tension with tension screw

Blades do not cut - Size cylinder defective

- Push rod defective

- Clipper head worn out

- Blades are blunt

Replace size cylinder

Replace push rod

*Replace clipper head

* Have specialised workshop resharpen blades

Clipper head gets very hot - Shear blade tension too high

- Shear blade and/or eccentric without lubri-

cating film

Reduce shear blade tension, poss.

resharpen blades and relubricate

with SAE 30 HD oil

Loading...

Loading...