3-13September 2004 90-FM200M-000

FM-200

®

ECS Series Engineered Fire Suppression Systems

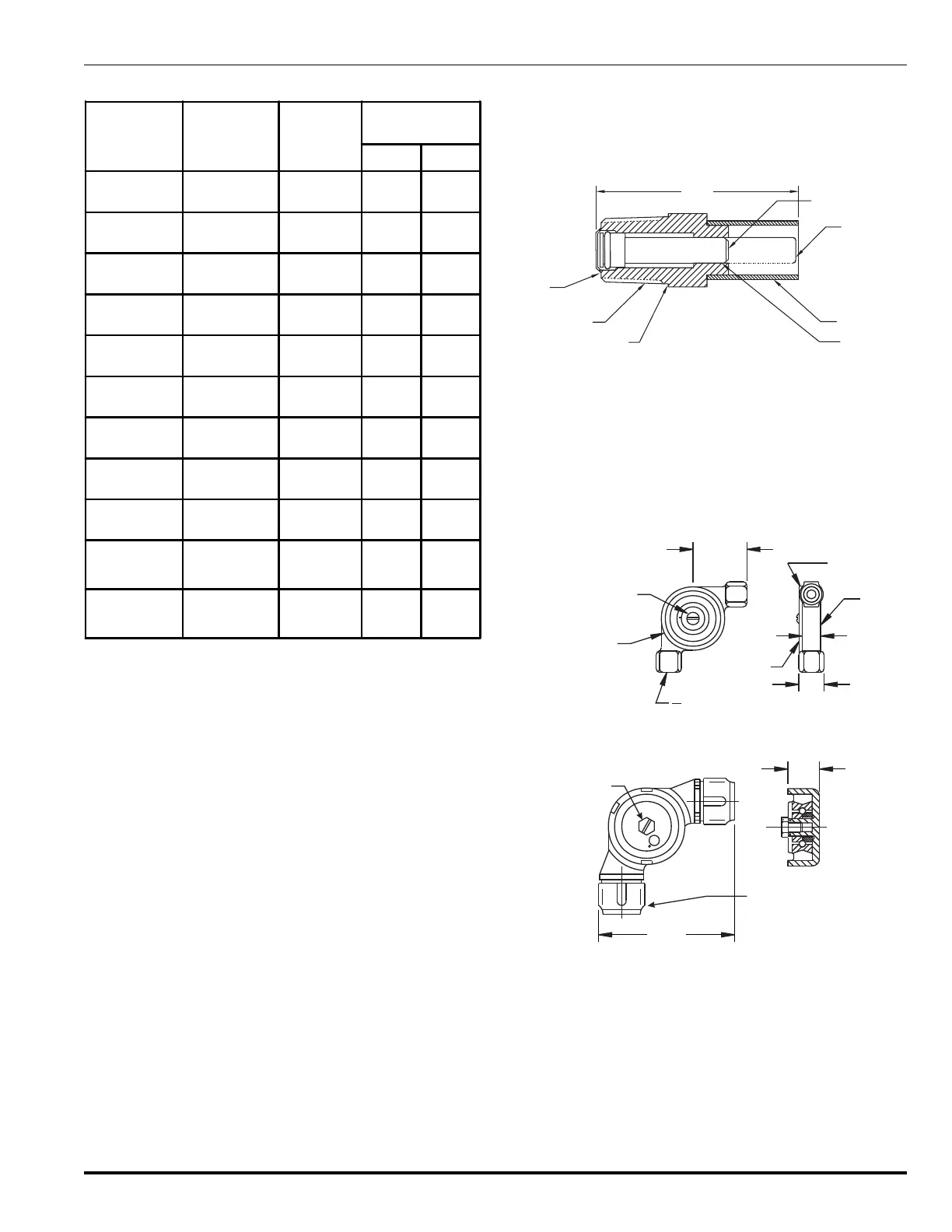

Table 3-16. Check Valves, Equivalent Lengths

Part Number Nomenclature Pipe Type

Equivalent

Length

ft. m

800327

Check Valve,

1/2" NPT

40 T & 40 W 7.0 2.13

800266

Check Valve,

3/4" NPT

40 T & 40 W 17.0 5.18

800443

Check Valve,

1" NPT

40 T & 40 W 12.0 3.66

800444

Check Valve,

1¼" NPT

40 T & 40 W 51.0 15.54

870152

Check Valve,

1½" NPT

40 T & 40 W 57.0 17.37

870151

Check Valve,

2" NPT

40 T & 40 W 165.0 50.29

870100

Check Valve,

3" NPT

40 T & 40 W 795.0 242.31

06-118213-001

Swing Check,

2"

40T & 40 W 13.4 4.06

06-118058-001

Swing Check,

3"

40 T & 40 W 13.0 3.96

877690 and

283899

2" EI check

and Flex Hose

40 T & 40 W 16.0 4.88

878743 and

283900

2½" EI check

and Flex Hose

40 T & 40 W 17.5 5.33

3-3.7.5 PRESSURE OPERATED SWITCHES,

P/N 486536 AND P/N 981332

Pressure Switches operate from system pressure upon dis-

charge to energize or de-energize electrically operated

equipment. Pressure switches may be used to shut down

machinery and ventilation or to annunciate system dis-

charge (see Figures 3-31 and 3-32).

3-3.7.6 PRESSURE OPERATED TRIP,

P/N 874290

Pressure Operated Trips are used to close off the hazard

space upon system discharge. The trips, operated by sys-

tem pressure, are designed to release self-closing units for

doors, windows and dampers. The maximum load to be

attached to a pressure trip is 100 lb. (45.36 kg). This is

based on a minimum pressure of 75 PSIG (50.7 bar gauge)

at the pressure trip.

3-3.7.7 DISCHARGE INDICATOR, P/N 875553

The Discharge Indicator may be installed in the discharge

piping to visually indicate a system discharge. When in the

SET position, the discharge indicator acts as a vent (see

Figure 3-28).

2.62"

(67 mm)

BODY

NPT MALE

0.93"(24 mm) HEX

ACROSS FLATS

½”

POSITION

INDICATION

POSITION

DISCHARGE

NORMAL

STEM-RED

CAP

Figure 3-28. Discharge Indicator

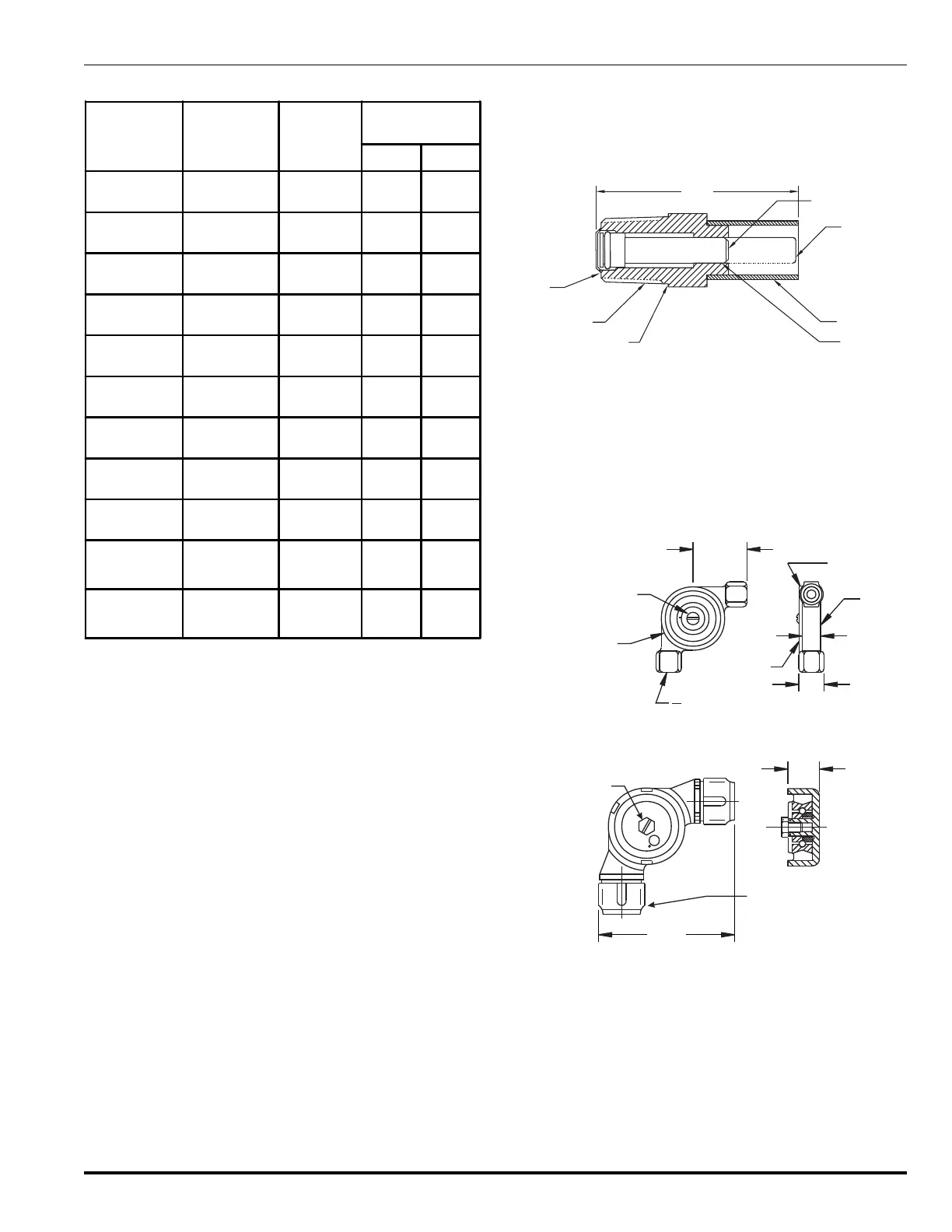

3-3.7.8 CORNER PULLEYS, P/N 803808

AND P/N 844648

Corner Pulleys change the direction of cable lines without

binding to ensure smooth operation. P/N 803808 is used

for all watertight applications; P/N 844648 is used for all

industrial applications (see Figures 3-29 and 3-30).

GASKET

BODY

COVER

0.62"

(16 mm)

0.81"

(21 mm)

1.75"

(45 mm)

COVER SCREW

2.13" (54 mm) DIA

-18 NPS FEMALE

3"

8

Figure 3-29. Corner Pulleys, Watertight Applications

U

L

COVER SCREW

2 - ½” E.M.T. CONNECTIONS

COMPRESSION TYPE

0.62"

(16 mm)

2.75"

(70 mm)

approx.

Figure 3-30. 1/2-Inch E.M.T. Corner Pulley,

General Applications

Loading...

Loading...