6-1September 2004 90-FM200M-000

FM-200

®

ECS Series Engineered Fire Suppression Systems

CHAPTER 6

POST-DISCHARGE MAINTENANCE

6-1 INTRODUCTION

Follow these procedures after the system has been acti-

vated and FM-200

®

has been discharged.

6-2 POST FIRE MAINTENANCE

6-2.1 FM-200 Valve Inspection and Service

Inspect and service the FM-200 valve as follows:

Note: ImportantBecause FM-200 tends to dissolve and

wash out lubricant, certain components in the

FM-200 valve assembly will have to be inspected

and serviced before recharging the cylinder/valve

assembly. Part numbers for items which may re-

quire replacement are listed in Table 6-1.

6-2.2 Valve Disassembly (1½", 2" and 2½")

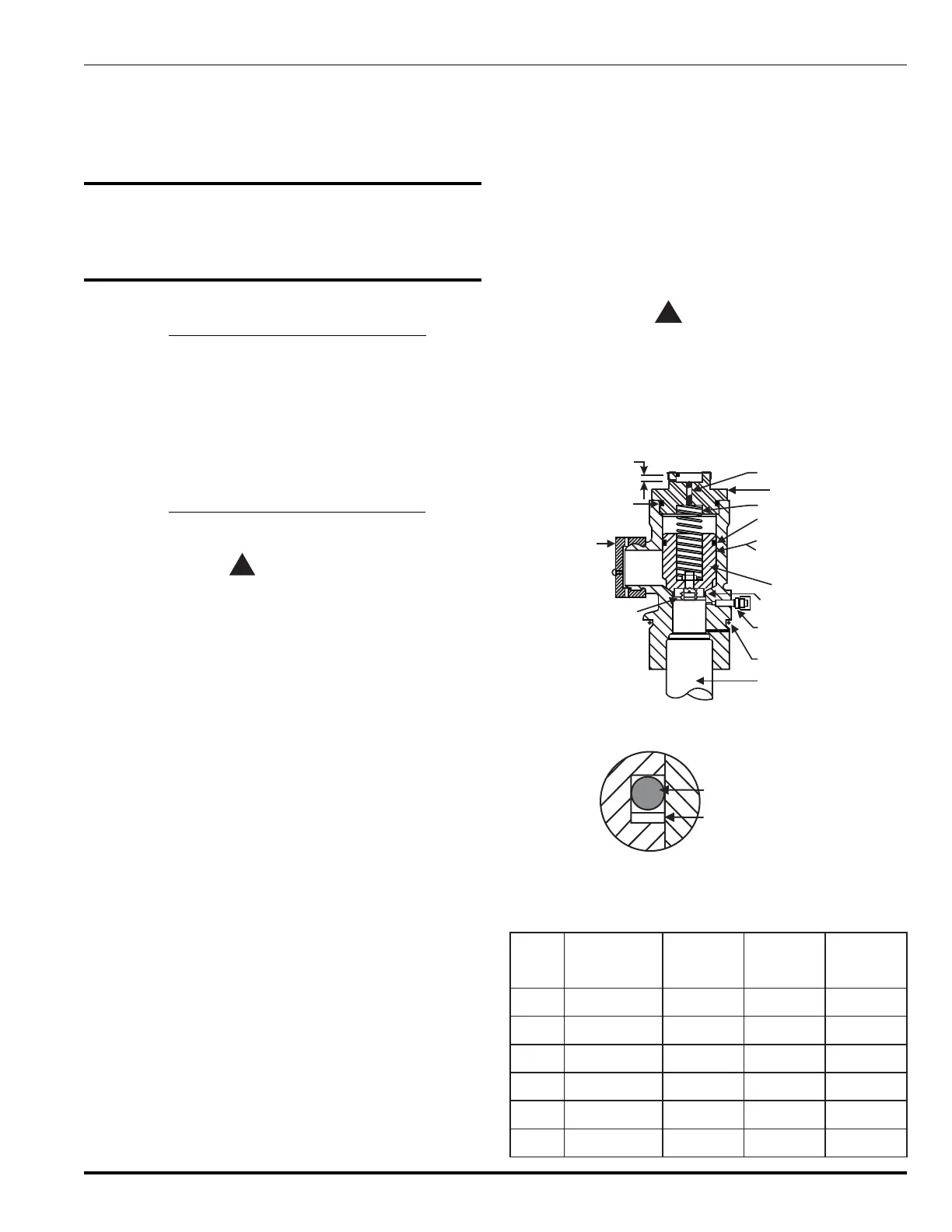

Refer to Figures 6-1 and 6-2 and Table 6-1.

WARNING

!

Before removing the valve, make sure that all

pressure has been relieved from the cylinder.

To relieve any remaining pressure, depress the

pressure switch Schraeder valve until all

pressure is relieved.

1. Remove the valve with the siphon tube from the cylinder.

2. Remove the O-ring. Examine the O-ring for cuts or nicks

and replace if necessary. Before reinstalling the O-ring,

apply a lubricant.

3. Remove the valve cap, spring and piston assembly.

Note: All internal components of FM-200 valves are re-

moved from the top of the assembly. However, if

there is excessive piston O-ring friction, the siphon

tube may have to be removed and the piston as-

sembly pressed out from the bottom.

4. Remove the O-rings and examine for cuts or nicks;

replace if necessary. Examine the O-ring grooves for

foreign matter. Before reinstalling the O-rings, apply

a lubricant.

5. Examine the exposed surface of the O-ring for nicks

and cuts. Also, ensure that the O-ring protrudes a mini-

mum or 0.020 in. (0.5 mm) above the conical seating

surface of the piston assembly. Replace this O-ring if

necessary by removing the seat retainer. Before reas-

sembly, apply a lubricant to the O-ring.

6. Examine the valve core pin for any evidence of bend-

ing or other damage. Depress the pin and make cer-

tain it snaps back freely. Replace the valve core if

necessary using a standard Schraeder core wrench.

When reinstalling a new Schraeder core element,

torque to 1½ to 3 in. lb. (0.17 to .37 N-m).

CAUTION

!

After reinstalling a Schraeder core, the distance

from the top of the core pin to the control head

seating surface must fall between the

dimensions of 0.515 in. to 0.565 in. (13 mm to

14 mm) when in the shut or non-actuated

position (see Figure 6-1).

SPRING

VALVE CAP

VALVE CORE

BACK-UP RING

O-RING, PISTON,

BACK-UP RING

(See enlarged view

in Figure 6-2.)

PISTON

O-RING SEAT

¬

¯

SIPHON TUBE

SAFETY

CAP

GAGING DIMENSIONS

.515/.565

O-RING CAP

SEAT RETAINER

O-RING, NECK

SUPERVISORY PRESSURE

SWITCH CONNECTION

°

±

®

Figure 6-1. Valve Assembly (1½", 2" and 2½")

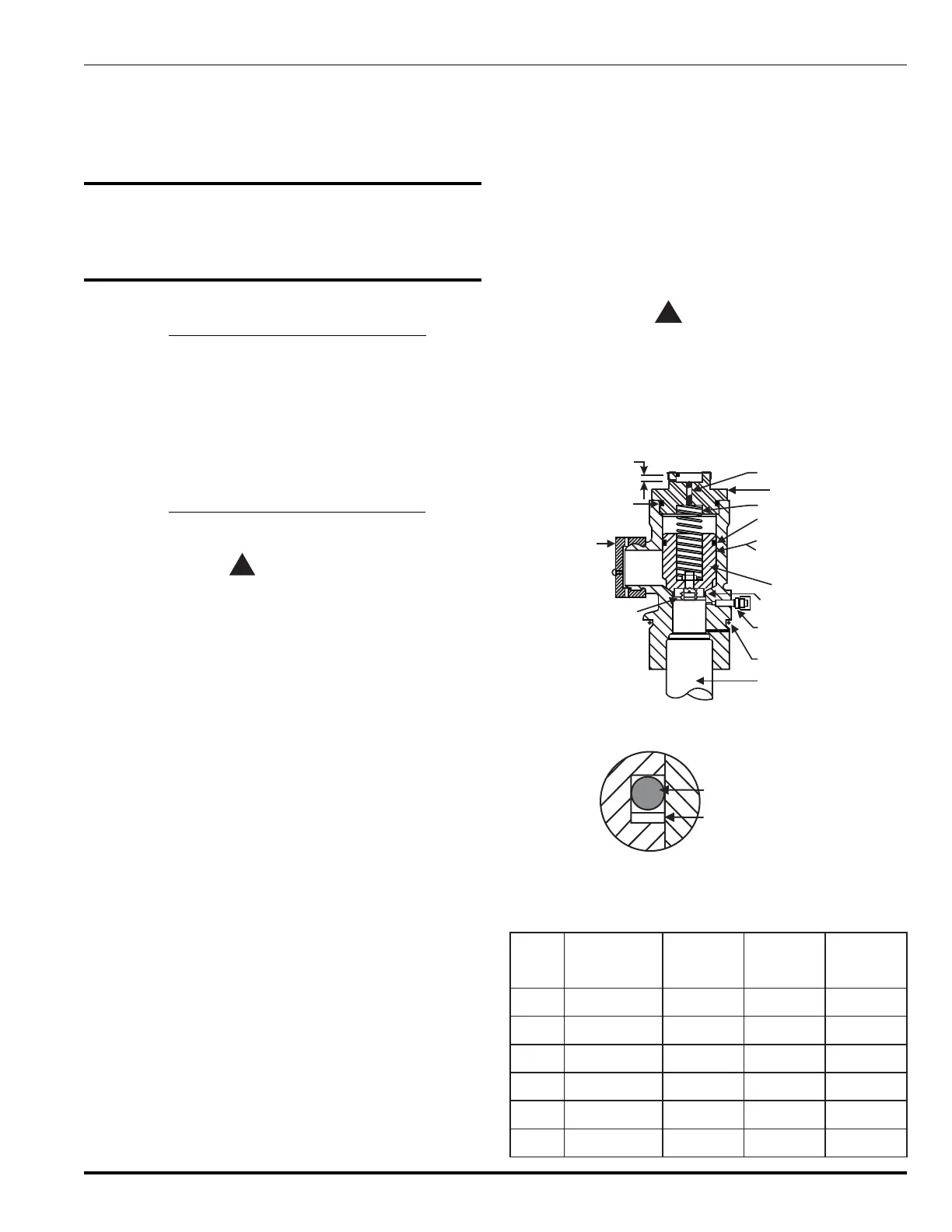

O-RING, PISTON

TEFLON BACK-UP

RING

Figure 6-2. Piston O-Ring

Table 6-1. Valve Components

erugiF

metI

.oN

noitpircseD

.bl521-01

srednilyc

.bl053-002

srednilyc

.bl006

srednilyc

1pac,gnir-O5220-16650320-166

54320-1665

2notsip,gnir-O5230-16650330-16654330-1665

3taes,gnir-O5120-16656230-16651330-1665

4kcen,gnir-O2390-166553

30-16659330-1665

5erocredearhcS872022872022872022

6gnirpu-kcaB052-300455003-300455043-300455

Loading...

Loading...