6-490-FM200M-000 September 2004

FM-200

®

ECS Series Engineered Fire Suppression Systems

6-2.7 Safety Disc Replacement (3")

The safety disc for the 3" valve is located on the cylinder

head, not on the cylinder valve.

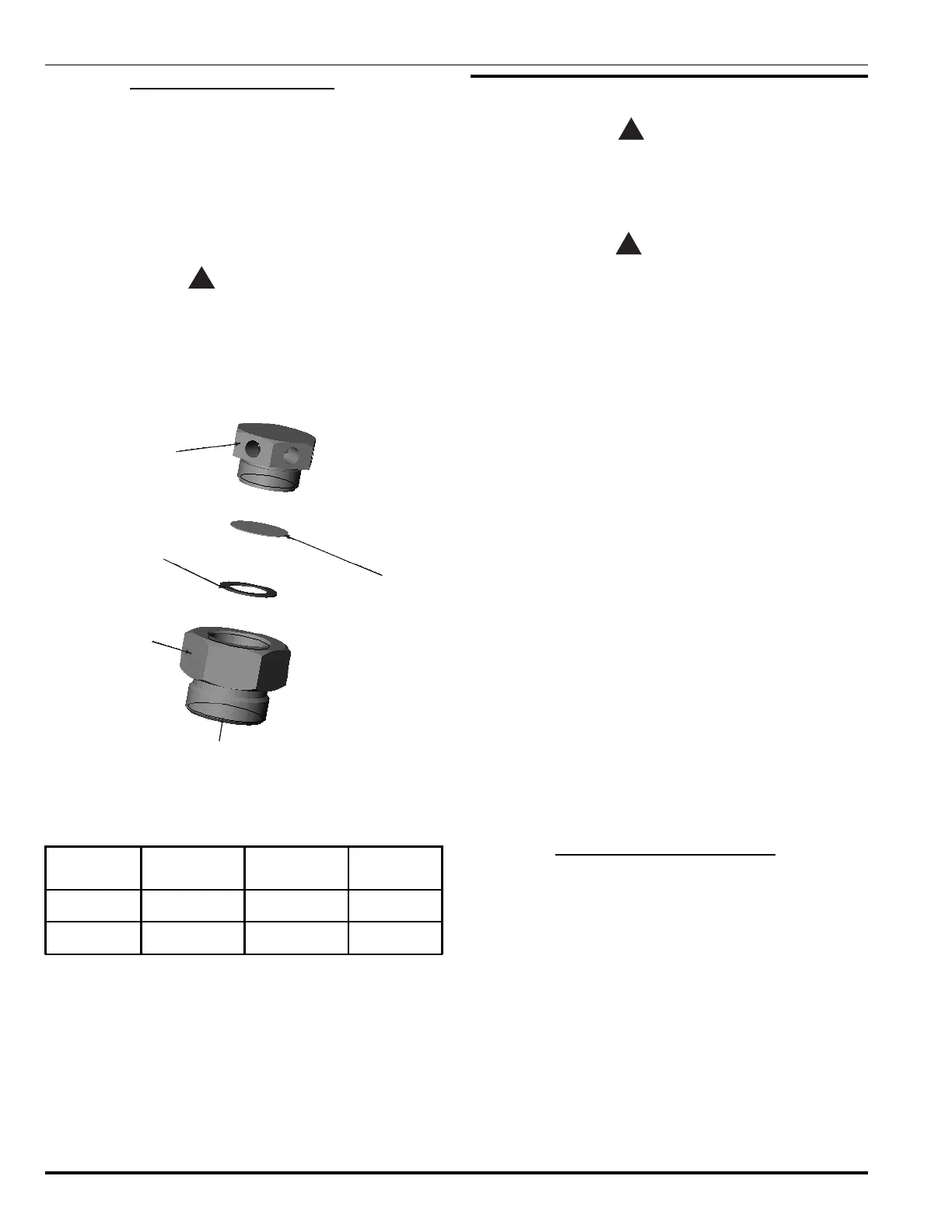

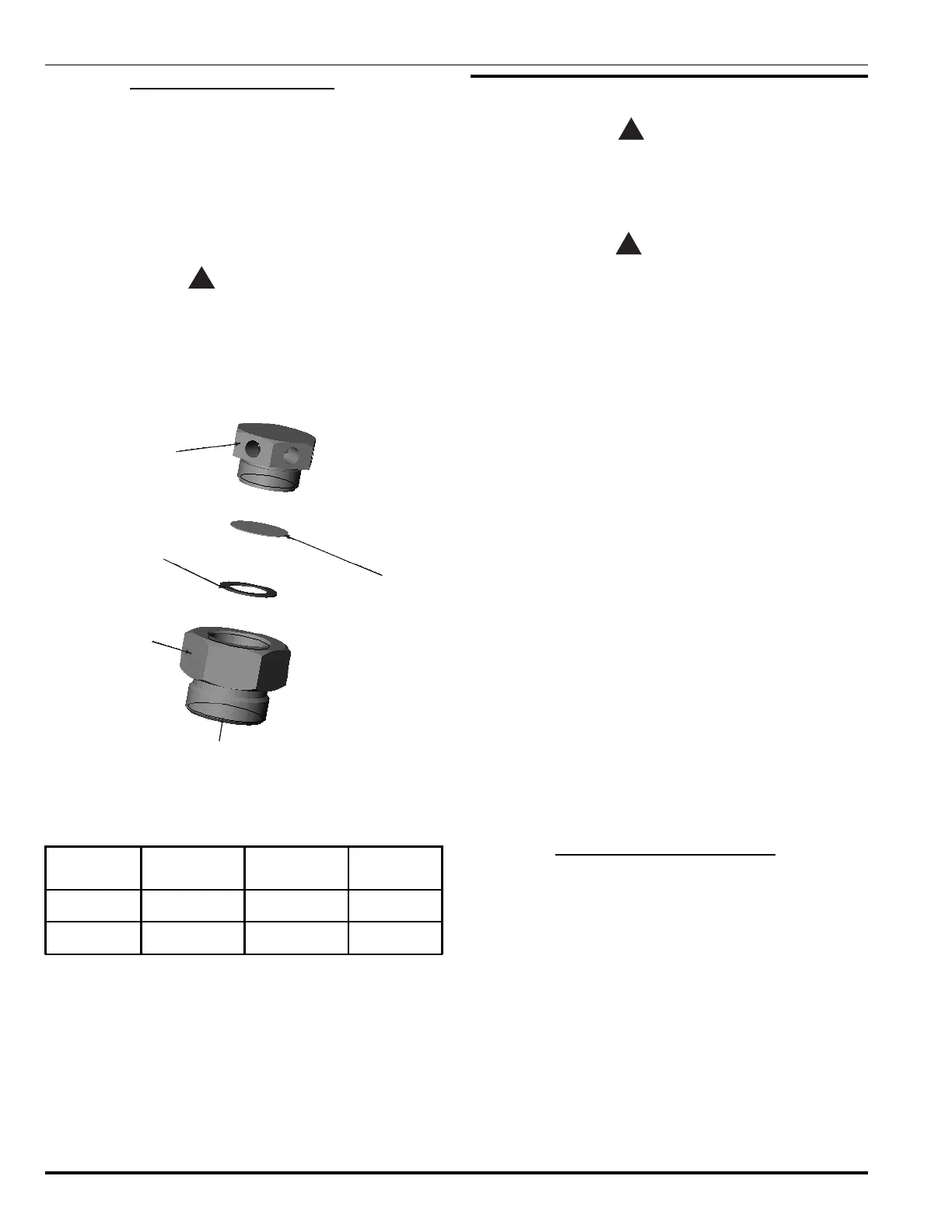

1. Remove the safety disc retainer (see Figure 6-5) in-

cluding safety disc and safety disc washer from the

cylinder body. Discard the safety disc and washer.

2. Reassemble the safety disc retainer with a new safety

disc and safety disc washer to the valve body. Torque

to the appropriate value listed in Table 6-5.

WARNING

!

Never install any type of disc other than

specified in Table 6-5 for the corresponding

cylinder. Installing the incorrect disc could

result in a violent rupture of the cylinder and

serious injury.

Safety Disk Retainer

06-235926-001

Safety Disk Washer

06-118185-001

Burst Disk

06-235926-001

Safety Disk

06-118184-001

Burst Disk Holder

06-236063-001

Figure 6-5. Burst Disc

Table 6-5. Safety Disc Replacement Table (3")

Cylinder Size Safety Disc P/N Torque Value PSIG @ 70° F

600 lb. 06-118184-001 90 ft. lb. 800-975

900 lb. 06-118184-001 90 ft. lb. 800-975

6-3 RECHARGING FM-200 CYLINDERS

CAUTION

!

FM-200 cylinders may require retest before

recharging (see Paragraph 5-5 for details on

cylinder retest). FM Approval is based upon the

usage of factory filled FM-200 cylinders.

WARNING

!

Under no circumstances while performing

either cylinder recharge or leak test, should a

charged cylinder be allowed to stand freely

without either the charging apparatus attached

or the safety cap installed. Whenever these

devices are not installed, a charged cylinder

must be securely clamped to a rigid structure

capable of sustaining the full thrust that would

result should the valve inadvertently open. The

clamping device and supports must be capable

of withstanding a thrust force of 1800 lb. (816.5

kg). This approximates the thrust force

generated out of the FM-200 cylinder valve

outlet on a full, wide-open discharge.

FM-200 charging equipment consists of an FM-200 stor-

age container, piping adapter, control valves, strainer, pres-

sure gauge, flexible hoses, seating adapter, recharge

adapter, pump, regulated nitrogen supply, scale and inter-

connecting plumbing. Recharge equipment must be suit-

able for the purpose intended and must be compatible with

FM-200. A typical FM-200 charging system schematic is

shown in Figure 6-6.

Note: During recharge, cylinder pressure gauge is not to

be used to determine charging pressure.

Locate the charging equipment in a clean,

well-ventilated area near the FM-200 supply and

cylinder storage. There should be sufficient

room for moving the cylinders to and from the

charging equipment.

6-3.1 Charging Equipment Installation

Before assembling the charging equipment, apply Permacel

No. 412D Teflon

®

tape to all pipe threads.

Loading...

Loading...