6-7September 2004 90-FM200M-000

FM-200

®

ECS Series Engineered Fire Suppression Systems

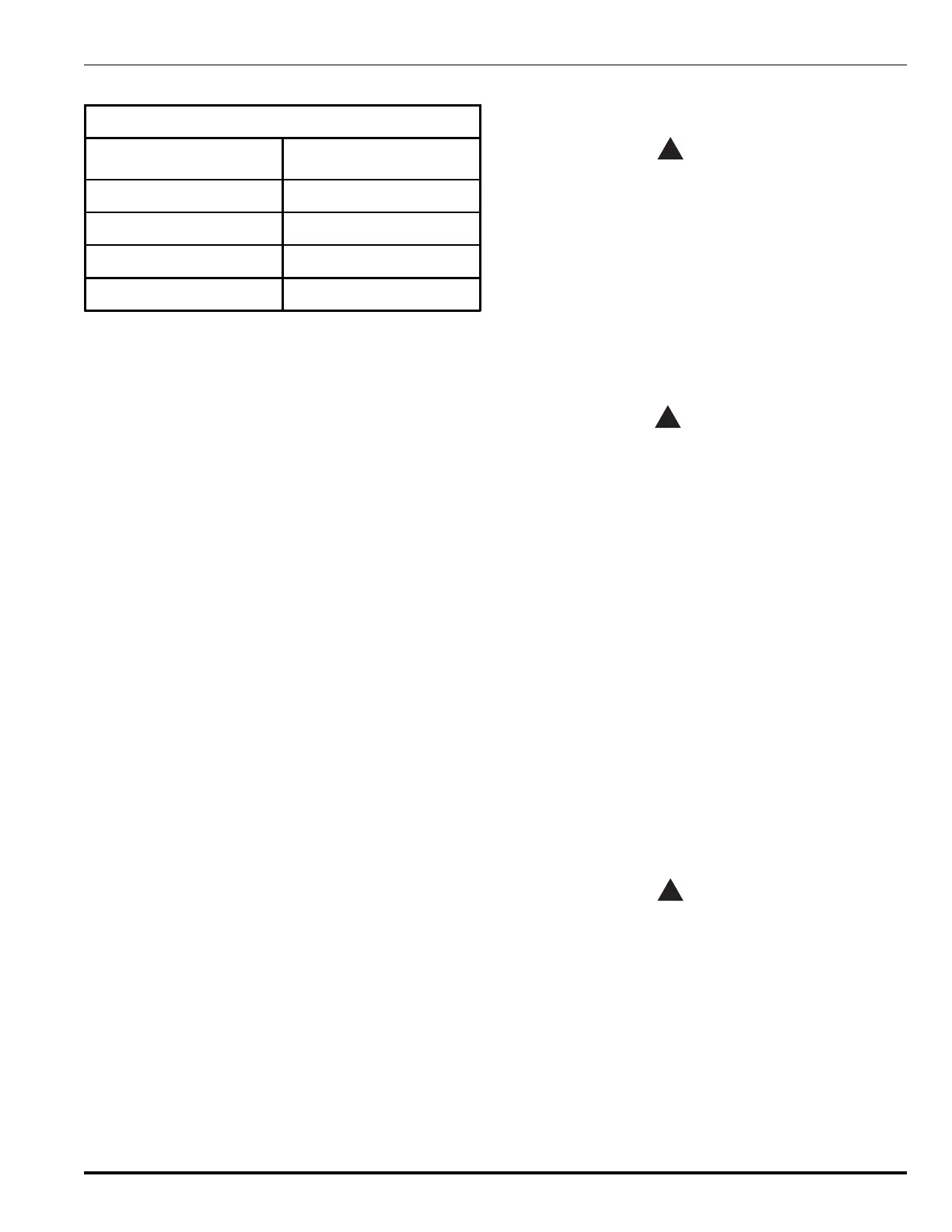

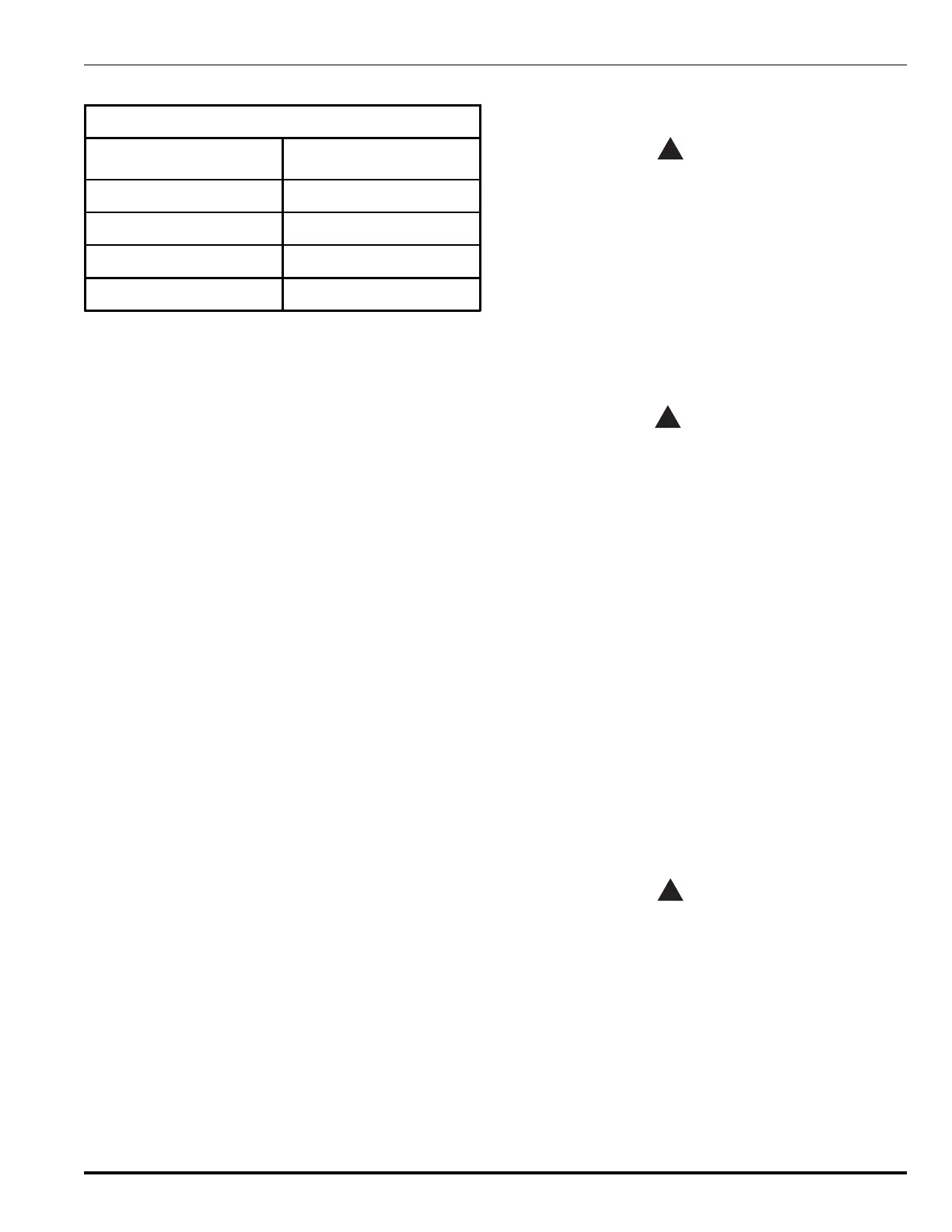

Table 6-7. Pressure vs. Temperature

Pressure versus Temperature

Temperature

o

F (

o

C)

Pressure

PSIG (bar gauge)

60 (15.6) 340 (23.5)

70 (21.1) 360 (24.8)

80 (26.7) 381 (26.3)

90 (32.2) 402 (27.7)

360 PSIG + 25, - 0 PSIG, at 70°F (25 bar gauge +1.7, -0

bar gauge at 21°C) is the final pressure required after the

charged container has had sufficient time to stabilize. Ni-

trogen topping may be required to attain the 360 PSIG (25

bar gauge) after the stabilization period has elapsed.

Nitrogen charge weight for Kidde FM-200 ECS Series En-

gineered Fire Suppression cylinders at 70 lb./ft.

3

(1121 kg/m

3

) fill density is based on 1.88 lb. (0.85 kg) of

nitrogen per 100 lb. (45.3 kg) of FM-200.

11. If nitrogen is required, open the handwheel valve on

the nitrogen supply valve (Item 16) and nitrogen valve

(Item 7). Adjust the regulator (Item 17) until the master

gauge shows a pressure indication of 360 PSIG + 25, -

0 PSIG (25 bar gauge + 1.7, -0 bar gauge).

12. Open the hose control valve (Item 29) and let the

nitrogen flow into the cylinder until the master gauge

indicates 360 PSIG (25 bar gauge). Cylinder agita-

tion will assist with the equilibrium of nitrogen and

FM-200. Additional nitrogen may be necessary as the

cylinder equilibrates.

13. Close the hose control valve (Item 29). Remove the pilot

actuation port protection cap and assemble the seating

adapter (Item 2) with the flexible hose to the cylinder valve

actuation port. Open valve (Item 6), then adjust the regu-

lator to momentarily apply 450 to 600 PSIG (31 to 41 bar

gauge) nitrogen pressure to the actuation port to firmly

seat the cylinder valve piston .

14. While momentarily maintaining pressure on the actua-

tion port, open vent valve (Item 4) on the recharge

adapter (Item 1) to rapidly vent FM-200 from the valve

assembly outlet port. The sudden pressure decrease

at the valve outlet will ensure the valve seat stays in

the closed position.

15. Leave vent valve (Item 4) open. Close valve (Item 6)

and open valve (Item 5) to vent nitrogen from the seat-

ing adapter.

CAUTION

!

Any hissing or discharge coming from vent

valve (Item 4) indicates that the piston is not

seated properly or has opened. If this occurs,

repeat Step 16. Verify that the cylinder valve

piston remains closed.

16. Keep vent valve (Item 4) open. Close valve (Item 5),

and once again open valve (Item 6) to reapply nitrogen

pressure to the actuation port. While momentarily main-

taining pressure on the actuation port, remove the re-

charge adapter (Item 1) from the cylinder valve outlet

port and immediately install the safety cap. Close the

vent valve (Item 4).

WARNING

!

Nitrogen pressure must be maintained on the

actuation port while removing the charging

adapter and installing the safety cap to ensure

that the cylinder valve does not inadvertently

actuate while the valve outlet port is wide open.

Failure to follow this could result in injury and

damage to property.

17. Close the nitrogen supply valve (Item 16) and

open vent valve (Item 5) to vent nitrogen from the

supply line.

18. Remove the seating adapter (Item 2) from the cylinder

valve and reinstall the actuation port protection cap.

Close valves (Items 5 and 6).

19. Weigh the fully charged cylinder. The weight must

agree with the weight stamped on the cylinder valve

nameplate. Record the date of recharge on the cyl-

inder record tag.

20. Monitor the cylinder valve gauge. The gauge indicator

must read 360 PSIG + 25 -0PSIG at 70°F (25 bar +1.7,

-0 bar gauge at 21°C) after the stabilization period.

21. The cylinder is now ready for the leak test (refer to Para-

graph 6-3.3).

CAUTION

!

The Kidde FM-200 series agent containers have

been designed for a maximum fill density of

70 lb./cu. ft. (1121 kg/m

3

) and super pressurized

with nitrogen to 360 PSIG + 25 PSIG at 70°F

(25 bar gauge +1.7, -0 bar gauge at 21°C). It is

important that these values not be exceeded.

Loading...

Loading...