6-890-FM200M-000 September 2004

FM-200

®

ECS Series Engineered Fire Suppression Systems

The pressure in the agent container is significantly affected

by fill density and temperature. At elevated temperatures,

the rate of increase in pressure is very sensitive to fill den-

sity (see Figure 1-1). If the maximum fill density is exceeded,

the pressure will increase rapidly with temperature increase

so as to present a hazard to personnel and property. Ad-

herence to the limits on fill density and pressurization lev-

els will prevent excessively high pressures from occurring

if the agent container is exposed to elevated temperature,

minimizing the possibility of an inadvertent discharge of

agent through the pressure relief device.

Note: When charging more than one FM-200 cylinder, it

may be advantageous to leave the pump (Item 14)

running. In this case, when a cylinder is full, rotate

the 3-way valve (Item 9) to direct the flow back to

the supply tank through the FM-200 return line. To

resume charging operations, return the 3-way valve

(Item 9) back to the Filling position.

To change the FM-200 shipping container (Item 25)

close cylinder valves (Items 19 and 22) close valves

(Items 21 and 24). Carefully open vent valves

(Items 20 and 23) to bleed pressure. Disconnect

charging lines from FM-200 supply cylinder. Posi-

tion new FM-200 supply cylinder in place. Connect

charging lines to new FM-200 supply cylinder, en-

suring vapor and liquid lines are connected to

proper valves. Close vent valves (Items 20 and 23).

Open valves (Items 21 and 24).

6-3.3 FM-200 Cylinder Leak Test

WARNING

!

Clamp FM-200 cylinder securely in place. The

clamping device and supports must be capable

of withstanding a thrust force of 1800 lb.

(816.5 kg). This approximates the thrust force

generated out of the FM-200 cylinder valve

outlet on a full, wide open discharge.

CAUTION

!

FM-200 cylinder leak tests must be conducted

in a well-ventilated area, away from the

charging station so as not to be influenced by

extraneous FM-200 vapors released during the

filling operations. Kidde recommends the

Yokogawa Type H25C leak detector for FM-200,

with the Yokogawa Type LS-20 leak standard

for FM-200 for calibrating the leak detector.

1. Warm up the leak detector for 30 minutes before pro-

ceeding with Step 2.

2. Calibrate the detector against the LS-20 leak standard

by holding the probe about 1/8 in. (3 mm) away, and

noting the meter deflection for the leakage allowance

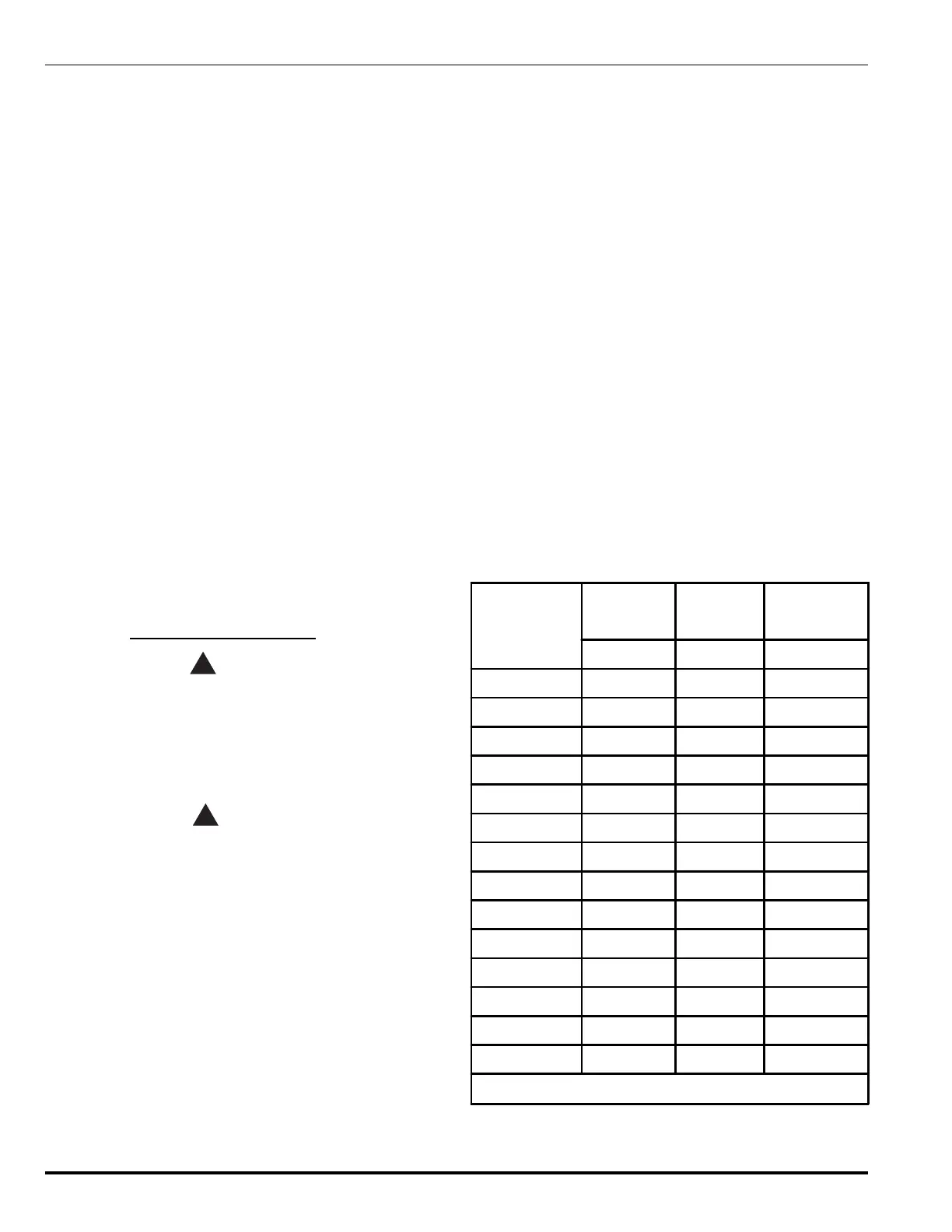

of the standard. Maximum allowable leak rates are

shown in Table 6-8.

3. Remove the safety cap from the discharge outlet. Blow

nitrogen on the surface where the plug was removed.

4. Move the probe back and forth slowly about 1/8 in.

(3 mm) away from all potential leak points (such as the

discharge outlet area, pilot check, valve bonnet, su-

pervisory pressure switch connection, safety outlet, liq-

uid level indicator, valve-to-cylinder connections, gauge

and container welds).

5. Meter deflections greater than indicated during cali-

bration are considered excessive and will be cause

for rejection.

6. Replace the safety cap immediately after the test.

7. If excess leakage is detected, salvage the FM-200

agent, perform the required maintenance on the con-

tainer and recharge.

8. After the leak test is complete, reassemble the protec-

tion cap to the actuation port of the valve assembly.

Unclamp the cylinder.

Table 6-8. Maximum Permitted Leakage Rates

Part Number

Cylinder Size

Cylinder Fill

Weight

Maximum

Allowable

Leakage

lb. lb. oz./yr.

90-100010-001 10 6-11 0.11

90-100020-001 20 9-23 0.20

90-100040-001 40 17 - 40 0.37

90-100070-001 70 30 - 70 0.67

90-100125-001 125 54 - 125 1.20

90-100200-001 200 86 - 200 1.81

90-100201-001 * 200 86 - 200 1.81

90-100200-101 200 86 - 200 1.81

90-100201-101* 200 86 - 200 1.81

90-100350-001 350 150 - 350 3.34

90-100351-001* 350 150 - 350 3.34

90-100600-001 600 258 - 600 5.74

90-100601-001* 600 258 - 600 5.74

90-10090X-001 900 390-900 8.68

*Note: Includes liquid level indicator

Loading...

Loading...