Chapter 4: Application guidelines

26 Alarmline II Digital Linear Heat Sensor Cable Technical Manual

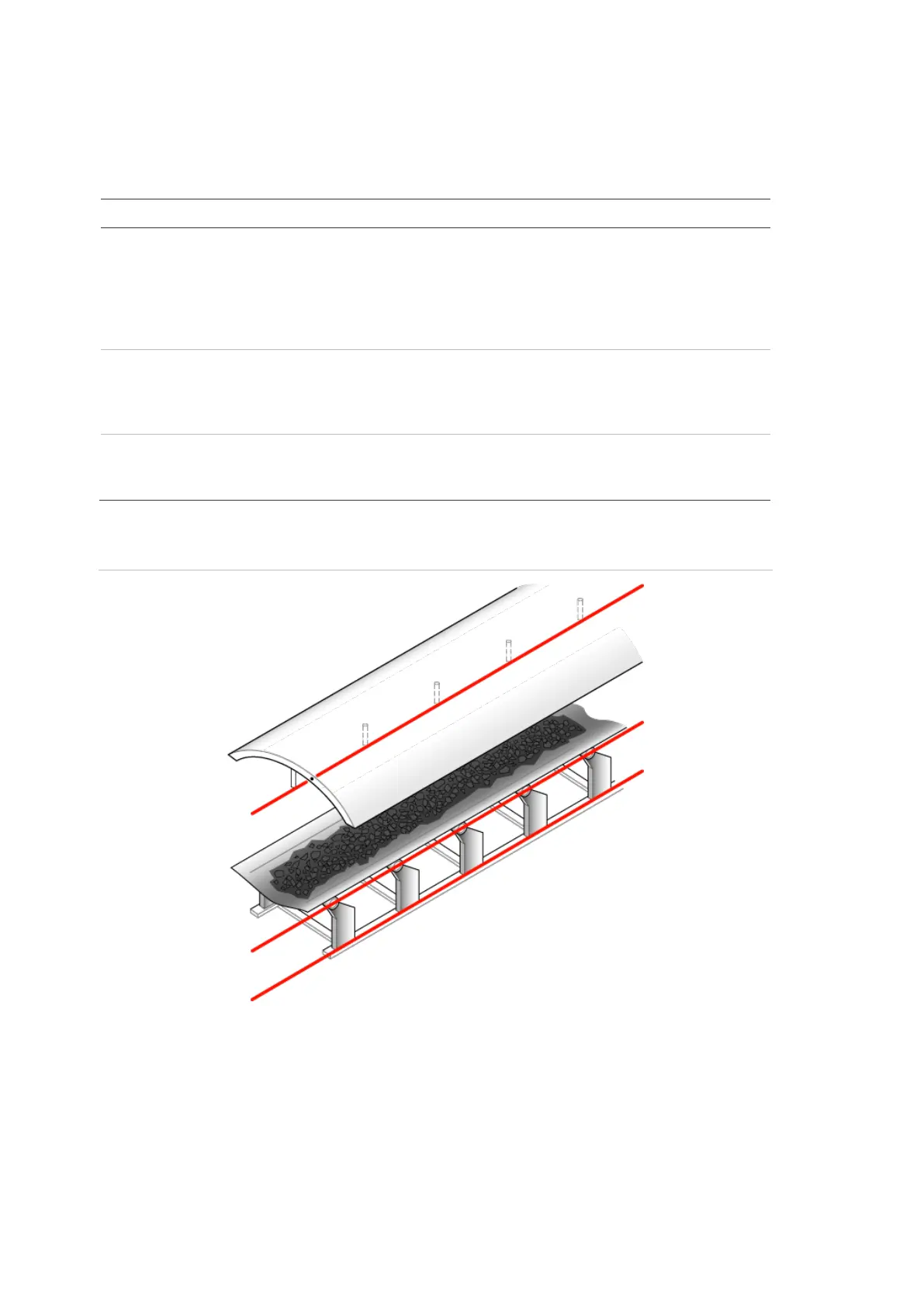

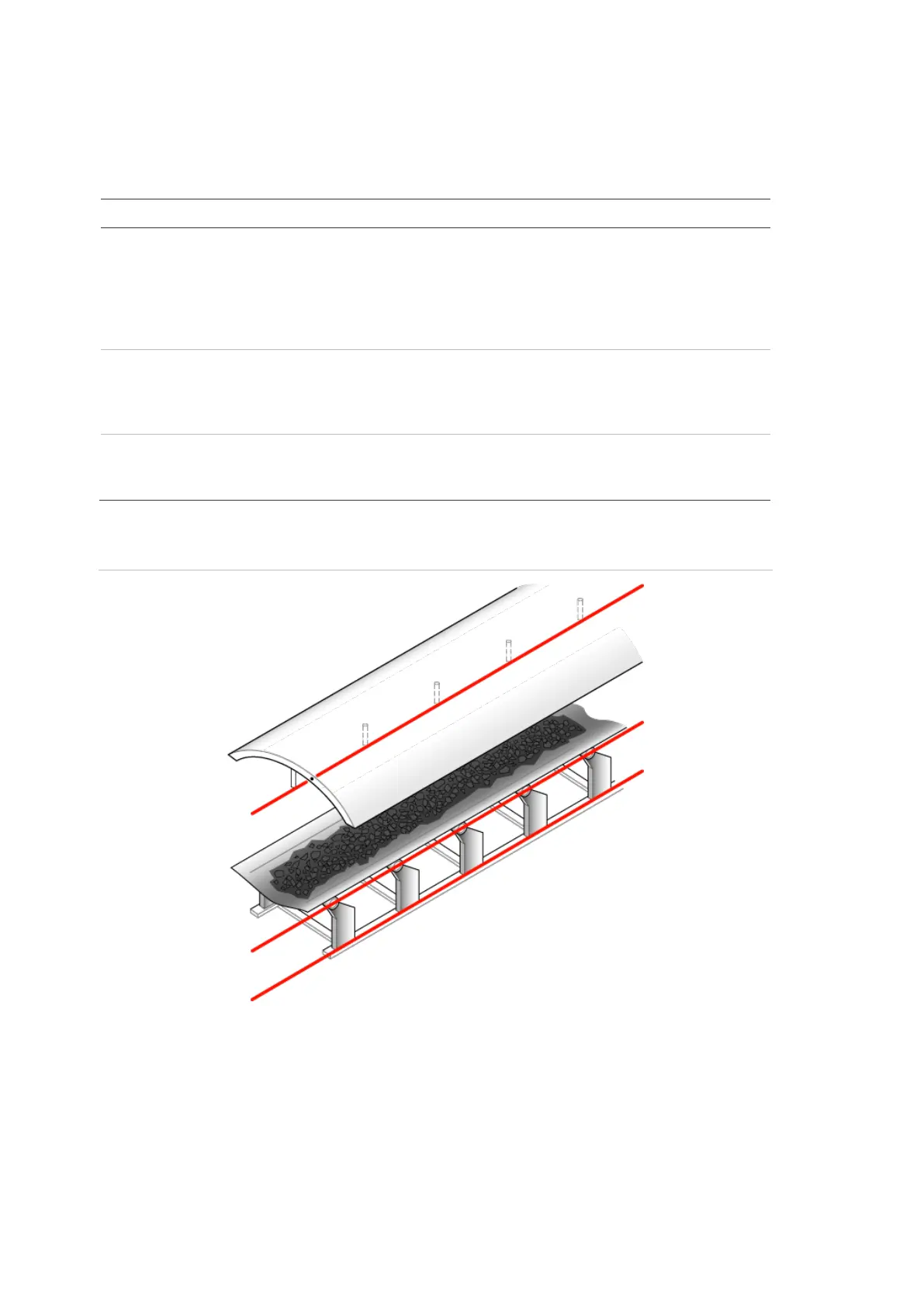

Three locations are recommended for the sensor cable to provide complete

detection on the conveyor belt.

Table 13: Recommended locations

Problems with friction from a misaligned belt or a seized bearing will

cause an overheat – by placing the sensor cable as close as possible to

the roller bearings the earlier a potential incident can be detected. A

controlled shutdown can be implemented preventing a potential fire

incident. It is recommended that cable is run down both sides of the

conveyor.

If the conveyor is covered it is recommended that sensor cable is fixed to

the canopy above the conveyor belt to detect for any fires on the belt,

enabling a controlled shutdown preventing potential fire spread by the

moving escalator.

It is a recommendation that sensor cable can also be installed

the conveyor to detect any fires that may occur due to trash or

combustible fuel that may have fallen from the conveyor belt.

Figure 4: Sensor cable installation for covered conveyor

The sensor cable should be installed in such a way as to not interfere with

maintenance and to prevent mechanical damage. Fixing clips should be selected

based upon fixing location and available fixing surfaces (most commonly edge

clips have been used to fit to the metal framework of the conveyor).

Loading...

Loading...