GL0014K Owners Handbook BioDisc BD, BE, BF, BG, ND, NE, NF, NG

Page 9

(4) BIODISC

Check that the BioDisc is in order, with no obvious damage or misalignment of parts. If any

possible problems are discovered, contact Klargester.

Check that all electrical components: Drive Motor, Sludge Return Pump and LOR Alarm

sensor, (where applicable) are connected to the Control Panel.

Units with FST Sludge Return System only: Check that the Sludge Return Timer in the

BioDisc Control Panel is set correctly, as indicated on the wiring diagram.

(5) AUTOMATIC GREASE CARTRIDGES

Where pressurised grease cartridges are fitted (to chain drives and/or roller bearings)

these must be activated before the unit

is started.

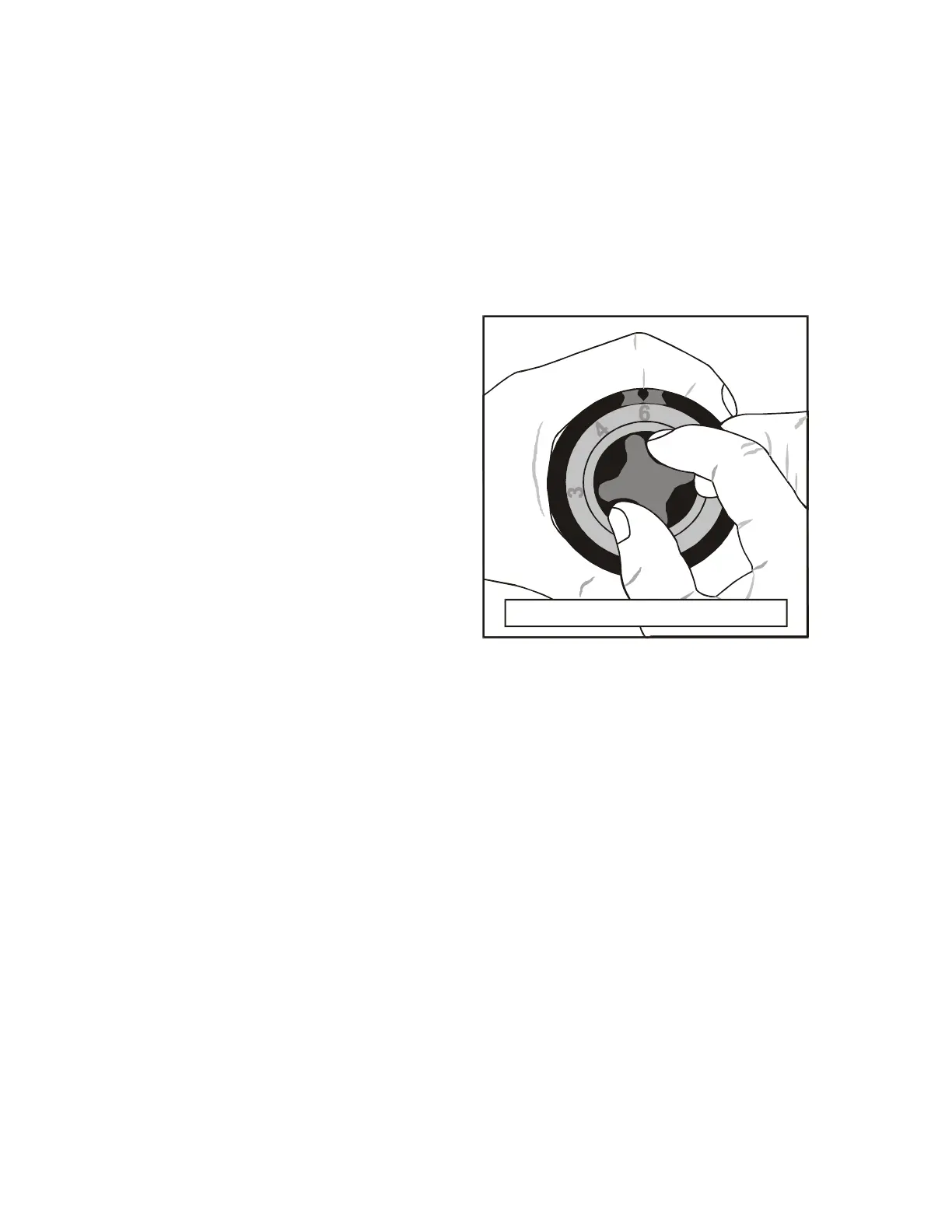

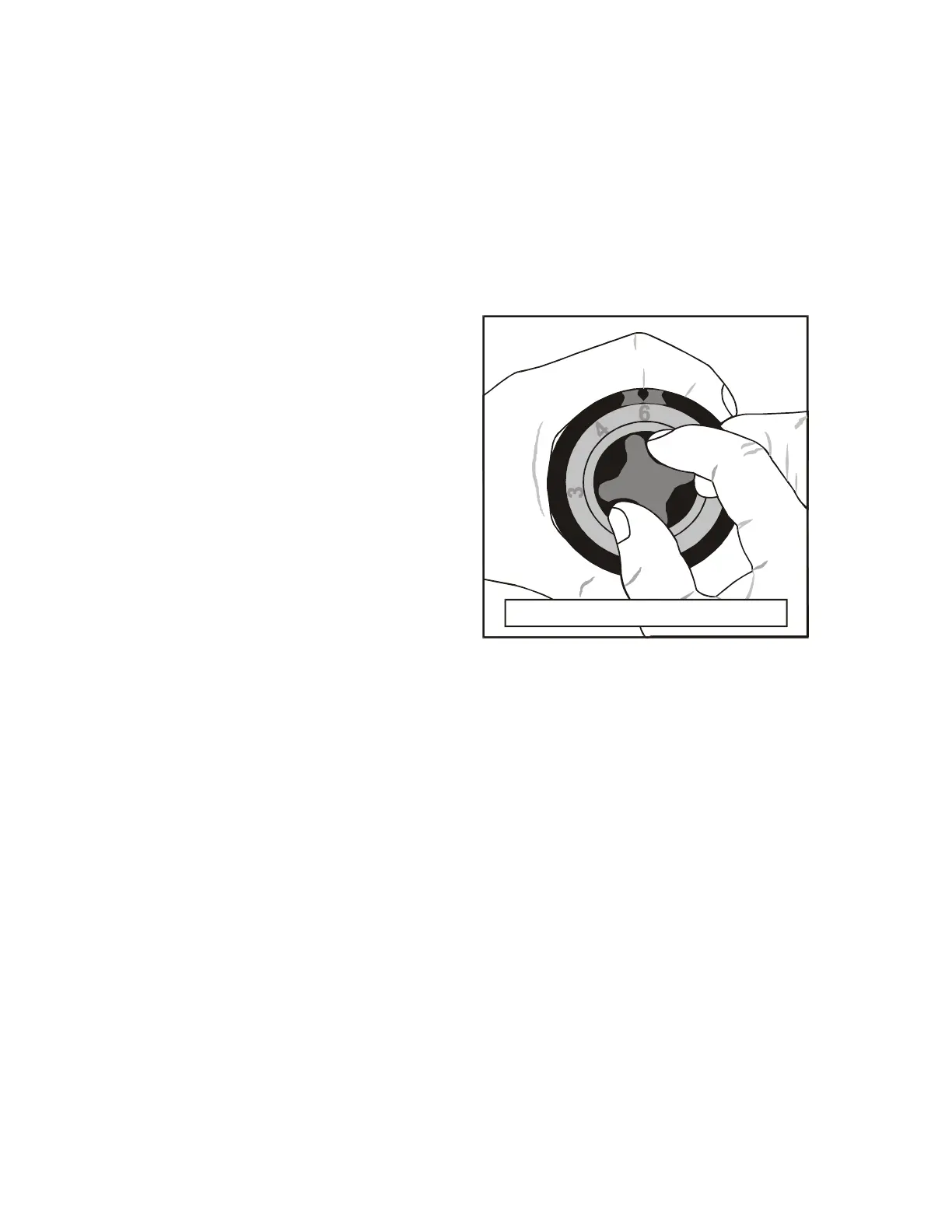

a) Turn the control knob and its linked dial

until the figure 6 is against the arrow on

the casing, as in Figure 3 (this should

give a lubrication period of 12 months at

the temperature in the BioDisc).

b) Depress the red button. This secures the

setting and releases the control knob

from dial.

Rotate the knob clockwise to activate the

unit.

(6) SWITCH ON

Open the Panel. Put the isolating switch and/or circuit breaker(s) into the “on” position.

Close the panel and lock it, if applicable. Note: If the unit is fitted with a the sludge return

pump, this should start and run for the set time when the unit is switched on.

(7) RUNNING CHECKS

Check that the rotor is running smoothly in the correct direction of rotation and is not

contacting any part of the fixed structure.

Check that the forward feed buckets are discharging correctly from the first to second stage

Biozone.

(8) OPTIONAL LOSS OF ROTATION ALARM

Where fitted, check operation of the Loss of Rotation (LOR) Alarm as follows:

a) Open the Control Panel and isolate the drive motor whilst maintaining power supply to

the alarm circuit. For units with a combined Alarm Control Panel this can be done either

by removing the motor fuse or by operating the motor overload trip (refer to wiring

diagram). Where a remote independent alarm is fitted, simply isolate power supply at

the BioDisc control panel. After a delay of 2-3 minutes the alarm should activate.

b) Push the reset button on the front of the Panel. The alarm beacon or sounder should

cease and the red indicator light on the panel front should remain illuminated.

c) Re-connect power to the drive motor and close the Control Panel. The alarm should

cease after approximately one minute.

d) Depress and release the “Beacon Off” button to reset it.

Malfunctioning of the LOR Alarm does not prevent operation of the BioDisc System, but it

should be reported to your maintenance engineer for early rectification.

Setting a discharge duration of 12 months

Fig. 3

Loading...

Loading...