Put frame halves into boathull:

Always look for a favorable level place, such as grass or a wooden dock. Lay out boathull all the way (about 17 feet long). Hull

is larger than woodwork, thus no forcing is needed. Rear end of hull has a metal rudderbracket.

Lift up front half (about 15 lbs.) and slide gently into front half of

hull, watching that sponson pockets rest evenly along the gunwales.

Lift up rear half (about 14 lbs) and slide gently through large cock-

pit opening towards the rear of boathull, again, watch sponsons. In

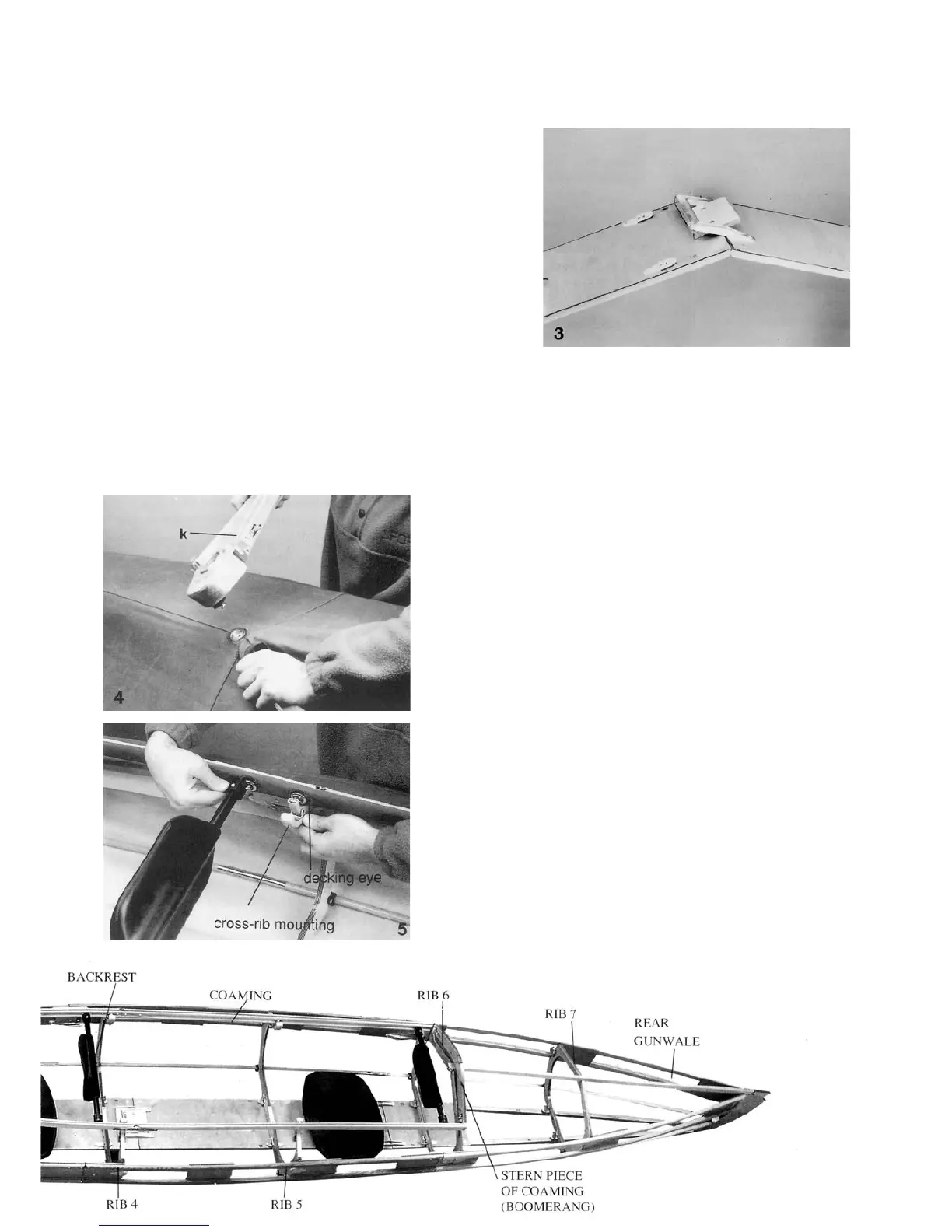

center of cockpit, woodparts will overlap. Lift up sections of keel-

board (fig. 3), and connect wooden tongue with metal horseshoe.

NOTE XXL model:You must connect an additional keelboard, gun-

wale (2) and rod extensions to the rear frame half. By pushing down

the extended keelboard, be sure both parts are pushed down simul-

taneously. Place your flat hand on the joint, and press down with

feeling - then hold down to avoid popping up. Gunwales are hinging

inward, connect wood tongue to horseshoe, press outward with

flat hand; pull filler tubes of sponsons through wood

structure to avoid squeeze. Now find the last two rods (51 in.), on

one end slide female over male sleeve, in the center pull sliding slee-

ve over short male, and locate head of screw to be visible to avoid damage at the hull.Take care at AE Tramp: Slide th rear

frame half into the hull this way, that the rear stern piece fits exactely into the notch of the hull. Make sure that the pushing

down of the two keelboards goes easily and the fitting for the rudder (outside) should not be pushed up or down.

Now put in the last three open crossribs # 3, 4 and 5. Begin with number 4 and connect the crossrib with the two snappers

at the keelboard at the same time. (numbers must face each other) Then click them into the gunwales and, after that, connect

the rods into the rod holders. Continue with crossrib # (4M, 5, 3)

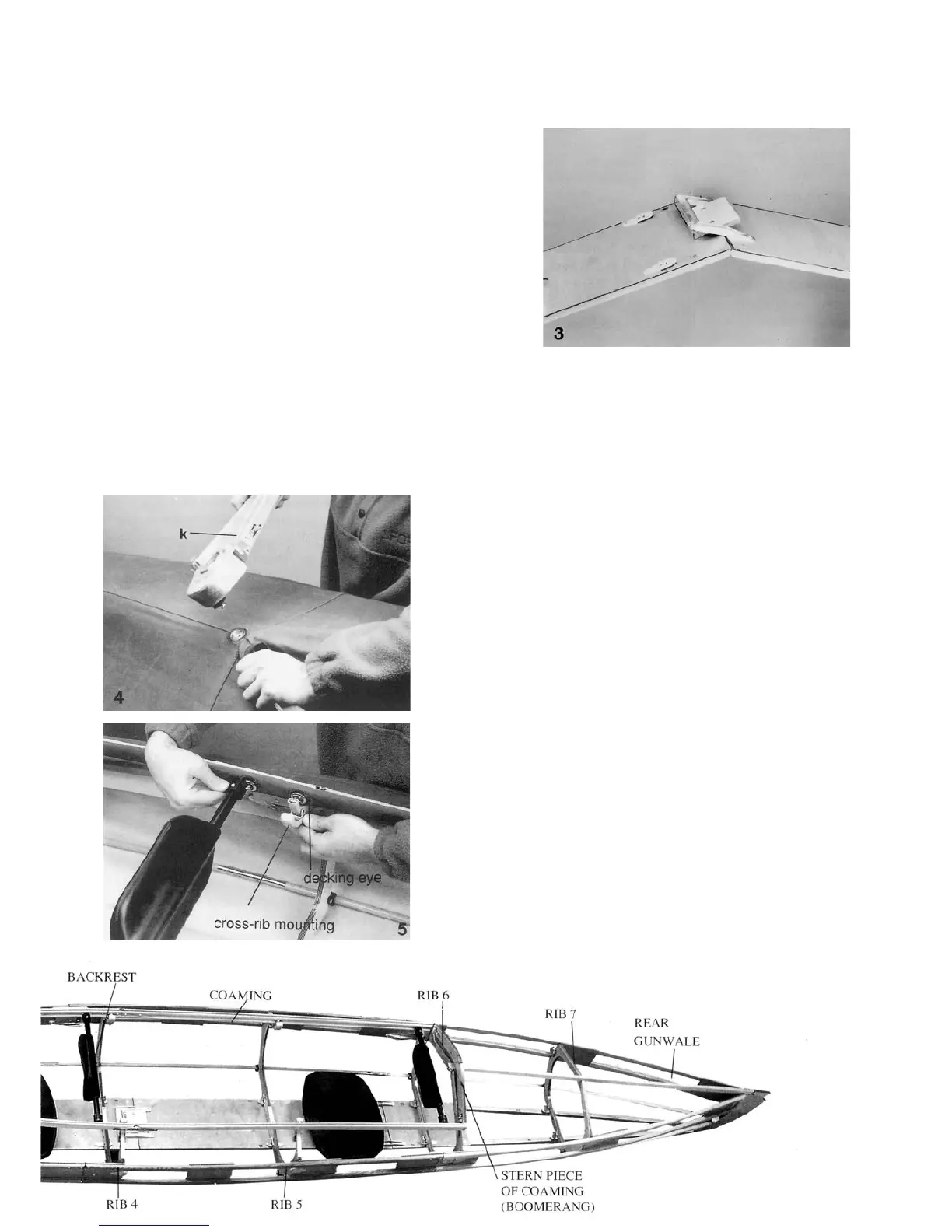

Placement of cockpit coaming:

Coaming consists of folded wood parts (k, fig. 4) and a

metal mast bracket with mast hole. Look under mast bracket, see T-

fitting. On deck is a grommet, through the grommet you should see

a rectangular hole, with a little pulling. - Hold coaming at a 90

degree angle to the boat axis, and insert T-fitting into hole.

With feeling, swing coaming (horizontally!) to settle over

cockpit of boat. Spread coaming apart. At location of ribs 3 and 4

(4M), T-fittings now are pushed through grommets, to rest exactly

in top of center levers (fig. 5)

Swing rear sections of coaming towards cockpit, attach

T-fittings to top of rib 5, and join rear - end fitting to hook on top

of rib 6. When all T-fittings stick through all grommets, then push

(press) thick edge of deck into groove of coaming, from above, it is

best to start in center.

Sternpiece of coaming (boomerang):

Side with 4 screwheads has to face cockpit. Push one end

downward into track, until screwhead there settles into notch.

Hook up 4 grommets over 4

screwheads, then press other end into track, settle screwhead into

notch (fig. 6).

Loading...

Loading...