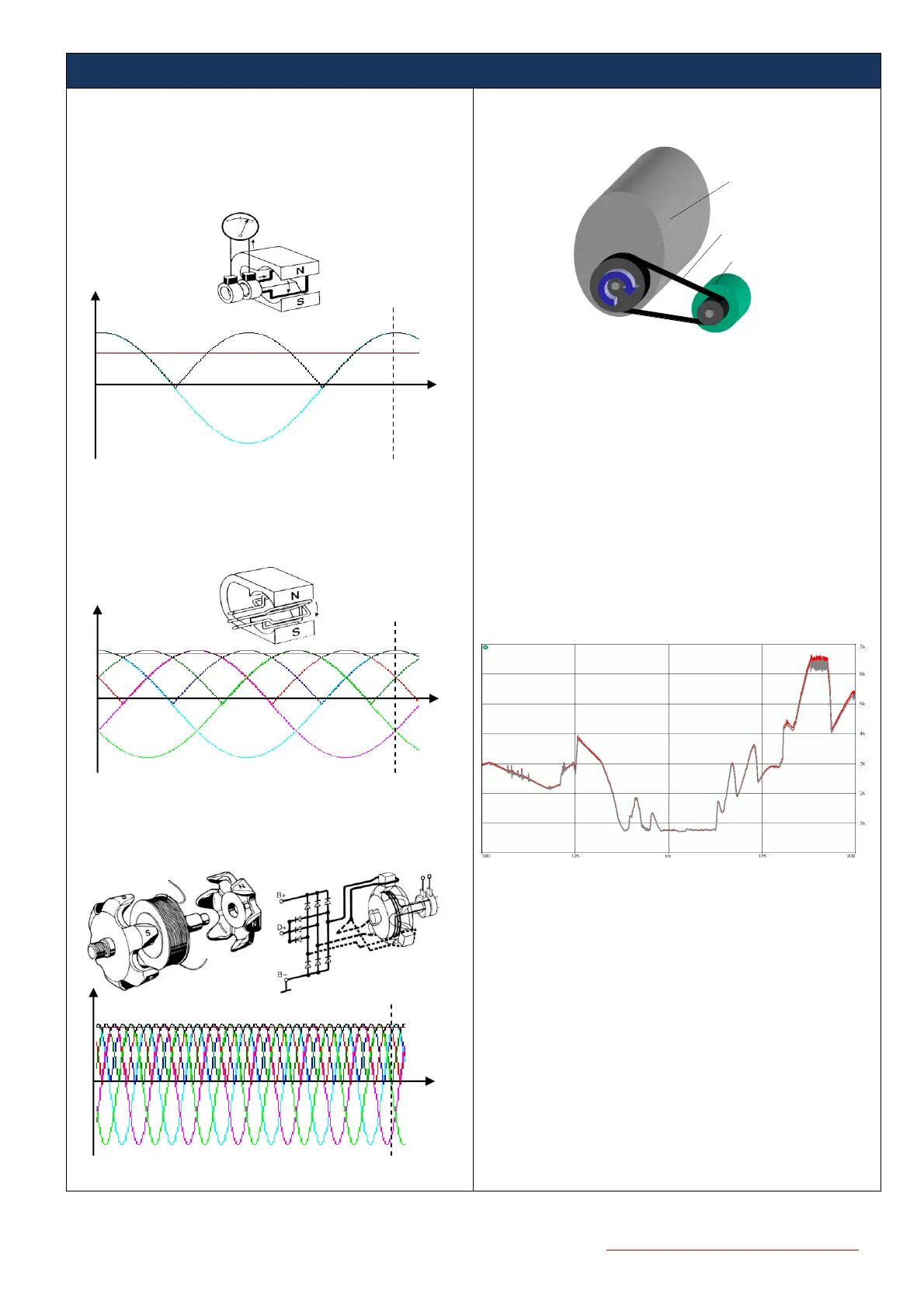

Considering the simplest physical generator with a rotating

wire winding inside a magnetic field produced by two magnetic

poles (one pole pair = north and south) - the output voltage is a

sine wave (blue line) with one cycle per revolution. After

rectification with diodes we get an alternating DC voltage with

2 pulses per revolution (black line) and a resulting average

voltage (brown line).

To imagine a three-phase generator we add two independent

wire windings. Now we have 3 sine wave voltages which are

spaced about 120° out of phase. After three-way rectification

with six diodes the result is an alternating DC voltage with 6

pulses per revolution (black line) and an increased average

voltage against the generator with one winding.

In practice generators for automobiles have more than two

poles. In most cases here we find 12 poles (6 pole pairs) and

sometimes also 16 poles (8 pole pairs). For the first one we get

from every phase 6 cycles per revolution and after rectification

an alternating DC voltage with 36 pulses.

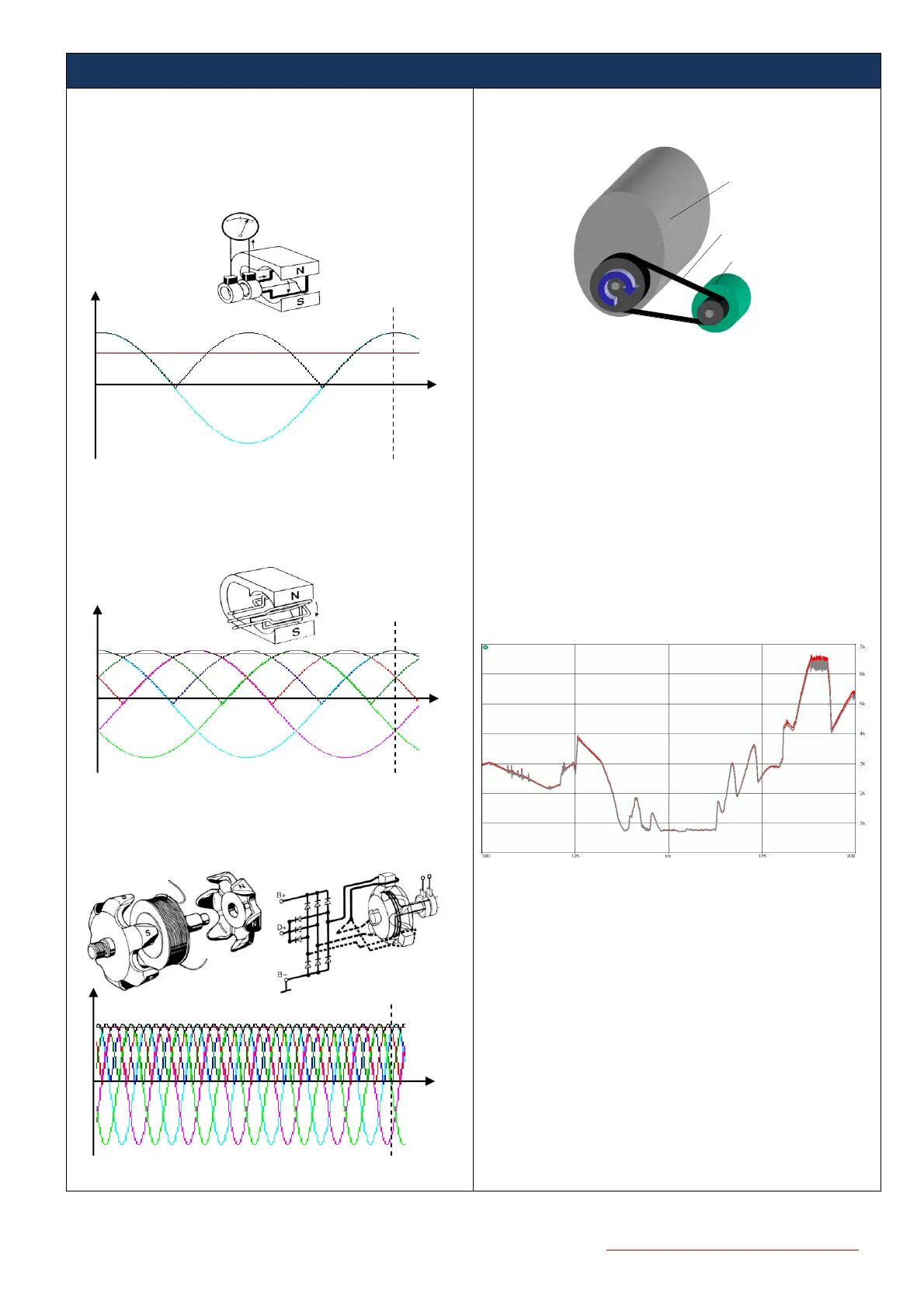

By connecting to an automotive cigarette lighter socket the

measurement unit RPM-8000 PRO senses the small AC ripple

of the vehicle board net DC supply voltage and generates on

its outputs both a TTL digital pulse train and an analog voltage

signal. These signals are “per design” linear to the alternator

RPM and by the linear drive belt relationship also to the engine

RPM. The scaling factor can determined by the relation

between the effective diameters of the engine and the

alternator pulleys.

Accuracy:

Next diagram shows a part of a test measurement of a famous

German automobile manufacturer. The RPM reference signal

was obtained from the car internal CAN bus, which will also

used for the electronically engine management. To verify the

dynamical performance, the RPM signal was provide with an

additional scaling factor of 1.02 - actually both curves are

congruent.

In practice the generated alternator ripple also includes

electrical noise and disturbances from other electrical devices

and loads connected to the vehicle supply. In petrol engine

vehicles this is mainly due to the ignition system and is

relatively straight-forward to eliminate. In Diesel engine

vehicles however the main noise source is from the electronic

injection system and, due to the spectral content of the

injection signals, is very difficult to decouple from the relatively

small signal of interest from the alternator. This technical

background helps to explain the different accuracies of the

RPM signal, which are achieved: approx. 0.5% for Petrol and

approx. 1.5% for Diesel engines. To improve the signal-to-

noise ratio, additional resistive loads such as rear window

heater and lights (not gas discharge lamps) should be

turned on. All inductive loads such as air conditioning

system, air blower, light dimmer, sliding roof and door

opener should remain off! This process increases the

accuracy of the output signal in every case

Loading...

Loading...