27

CARE AND MAINTENANCE

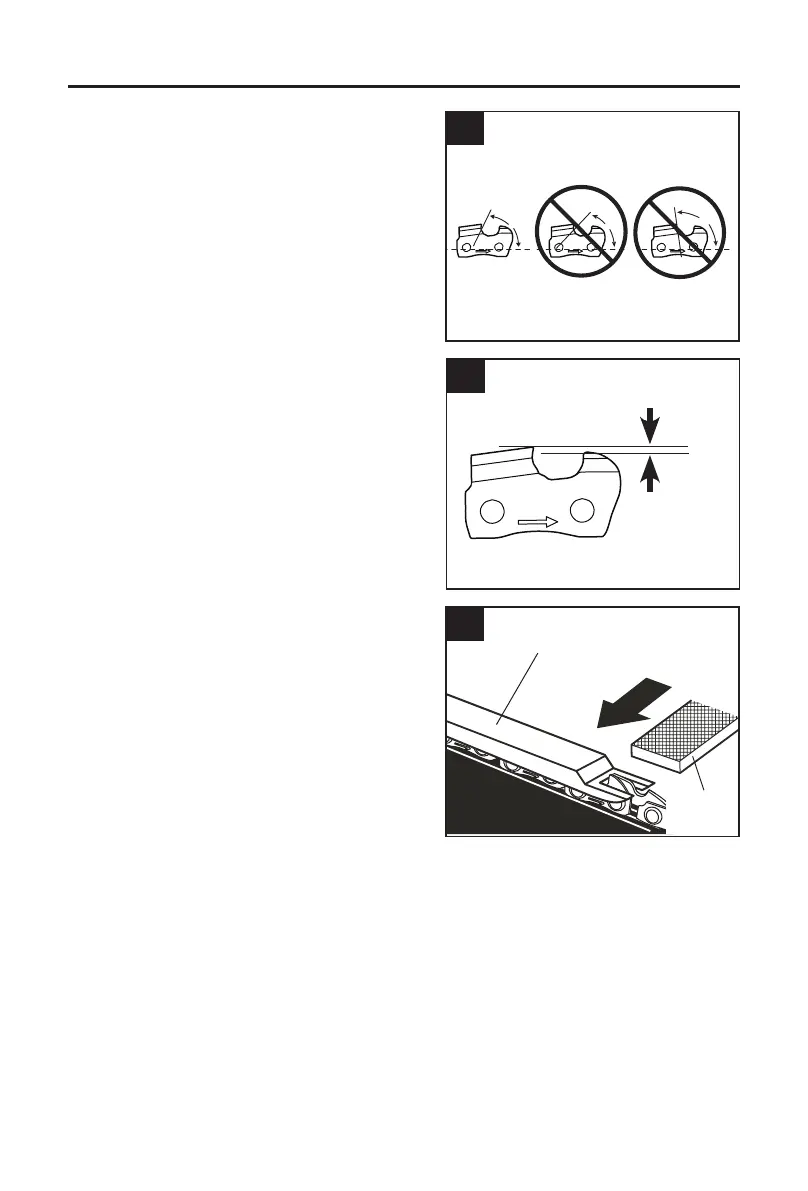

Side Plate Angle (Fig. 13f)

CORRECT 55° - The optimal angle can be

produced automatically if the correct diameter le is

used in the le holder.

HOOK - “Grabs” and dulls quickly. Increases

potential of KICKBACK. Results from using a le

with a diameter that is too small, or a le held too

low.

BACKWARD SLOPE - Needs too much feed

pressure, causes excessive wear to bar and chain.

Results from using a le with a diameter too large,

or a le held too high.

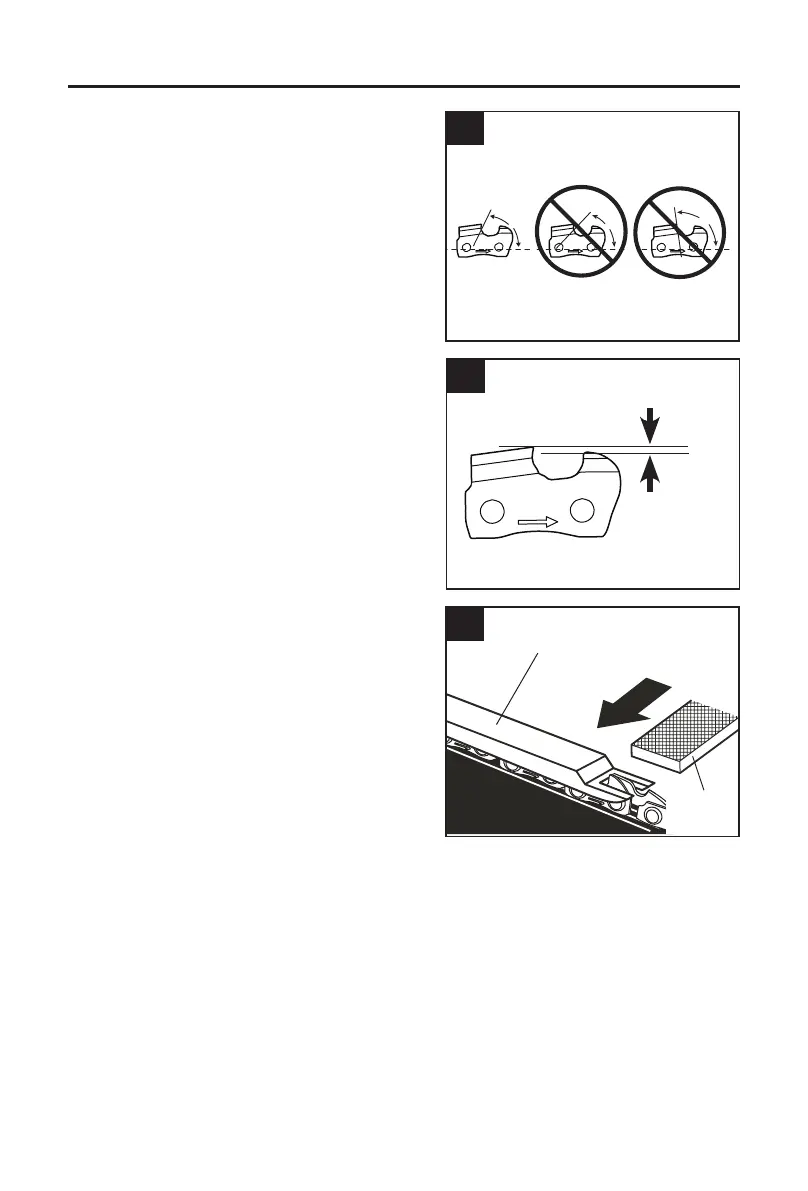

Depth-Gauge Clearance

a. The depth gauge should be maintained at a

clearance of 0.025 in. (0.6 mm), as shown in

Fig. 13g. Use a depth gauge tool (available

separately) to check the depth gauge

clearances.

b. Check the depth-gauge clearance every time

the chain is led. Use a flat le and a depth-

gauge jointer (both available separately) to

lower all gauges uniformly (Fig. 13h). Use a

0.025 in. (0.6 mm) depth-gauge jointer.

Depth-gauges must be adjusted with the flat le

in the same direction the adjoining cutter was led

with the round le. Use care not to contact the

cutter face with the flat le when adjusting depth

gauges.

13g

0.025" (0.6 mm)

Depth gauge clearance

55°

13f

CORRECT INCORRECT INCORRECT

Hook

Backward

Slope

Side plate angle

13h

Depth gauge jointer

Flat le

Loading...

Loading...