29

CARE AND MAINTENANCE

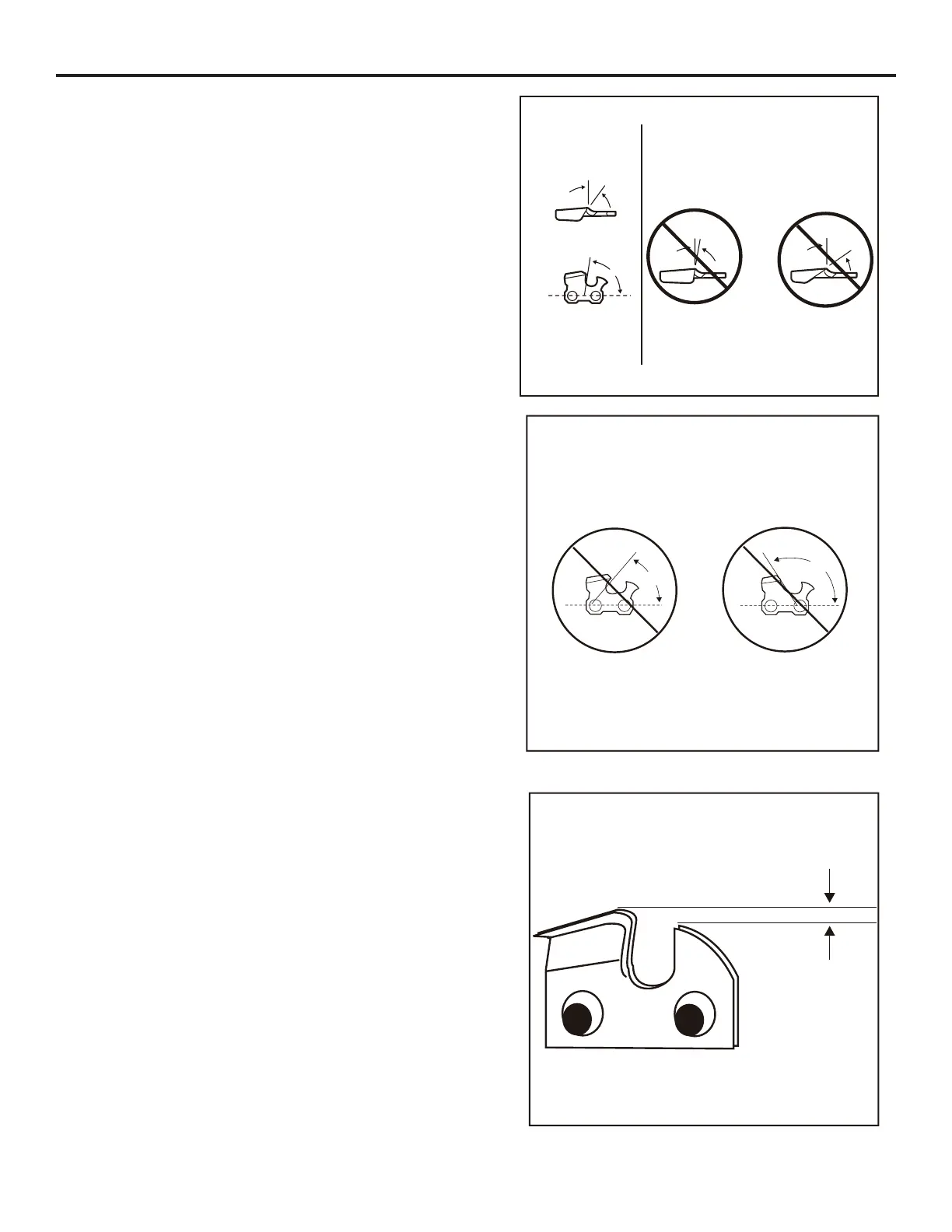

Top plate ling angle

• CORRECT 30° – le holders are marked with guide

marks to align le properly to produce correct top

plate angle.

• LESS THAN 30° – for cross cutting.

• MORE THAN 30° – feathered edge dulls quickly.

Side plate angle

• Correct 80° – Produced automatically if you use the

correct diameter le in the le holder.

• Hook – “Grabs” and dulls quickly; increases the

potential of kickback. Results from using a le with a

diameter too small or a le held too low.

• Backward Slope – Needs too much feed pressure;

causes excessive wear to the bar and chain. Results

from using a le with a diameter too large or le held

too high.

Side plate angle

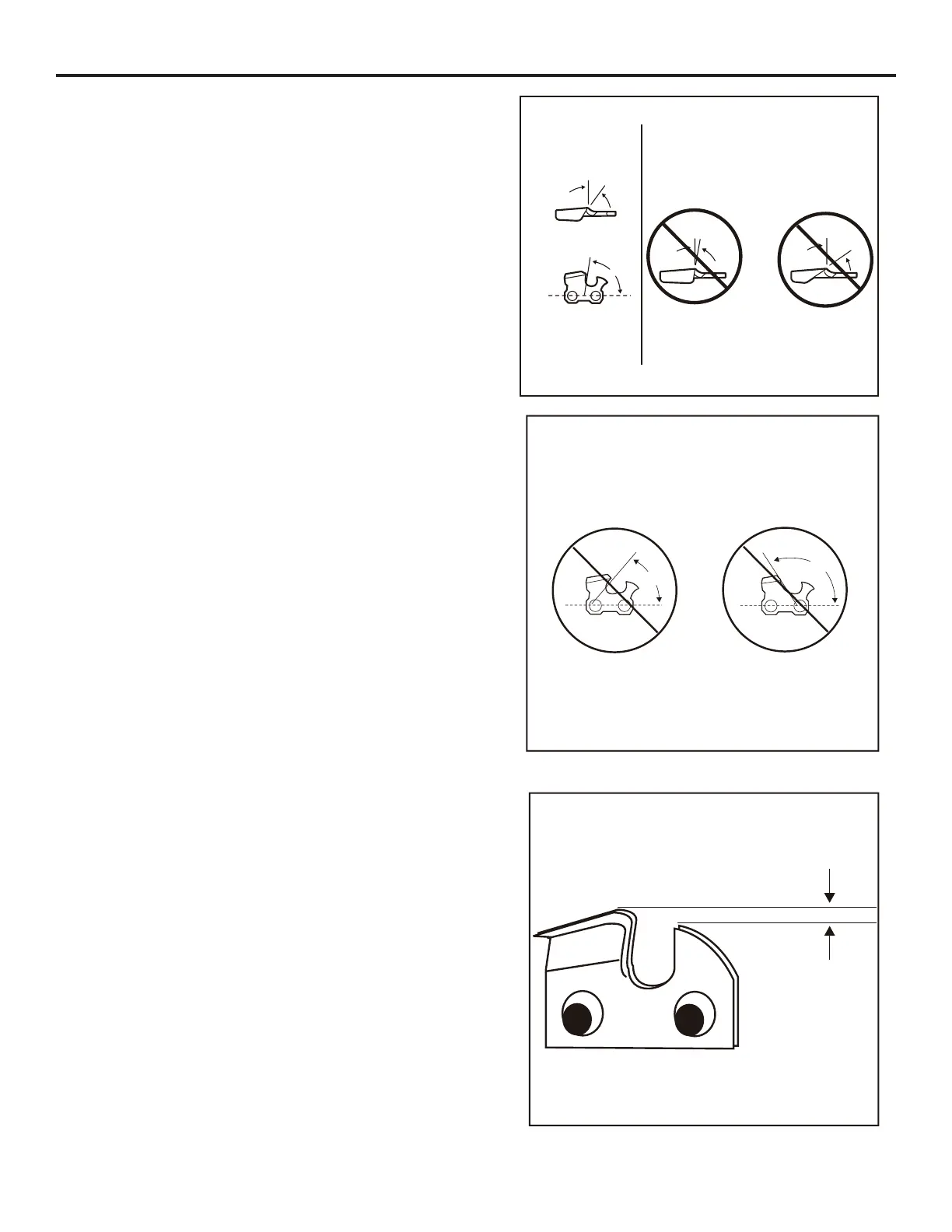

• Maintain the depth gauge at a clearance of 1/32 in.

(0.6 mm). Use a depth gauge tool for checking the

depth gauge clearances.

• Every time the chain is led, check the depth gauge

clearance.

30˚

80˚

TOP PLACE

FILLING ANGLE

SIDE PLATE

FILLING ANGLE

CORRECT INCORRECT

LESS THAN 30° MORE THAN 30°

Hook

Incorrect

Backward Slope

Raker (Depth Gauge) Clearance

1/32”

(0.6 mm)

Loading...

Loading...