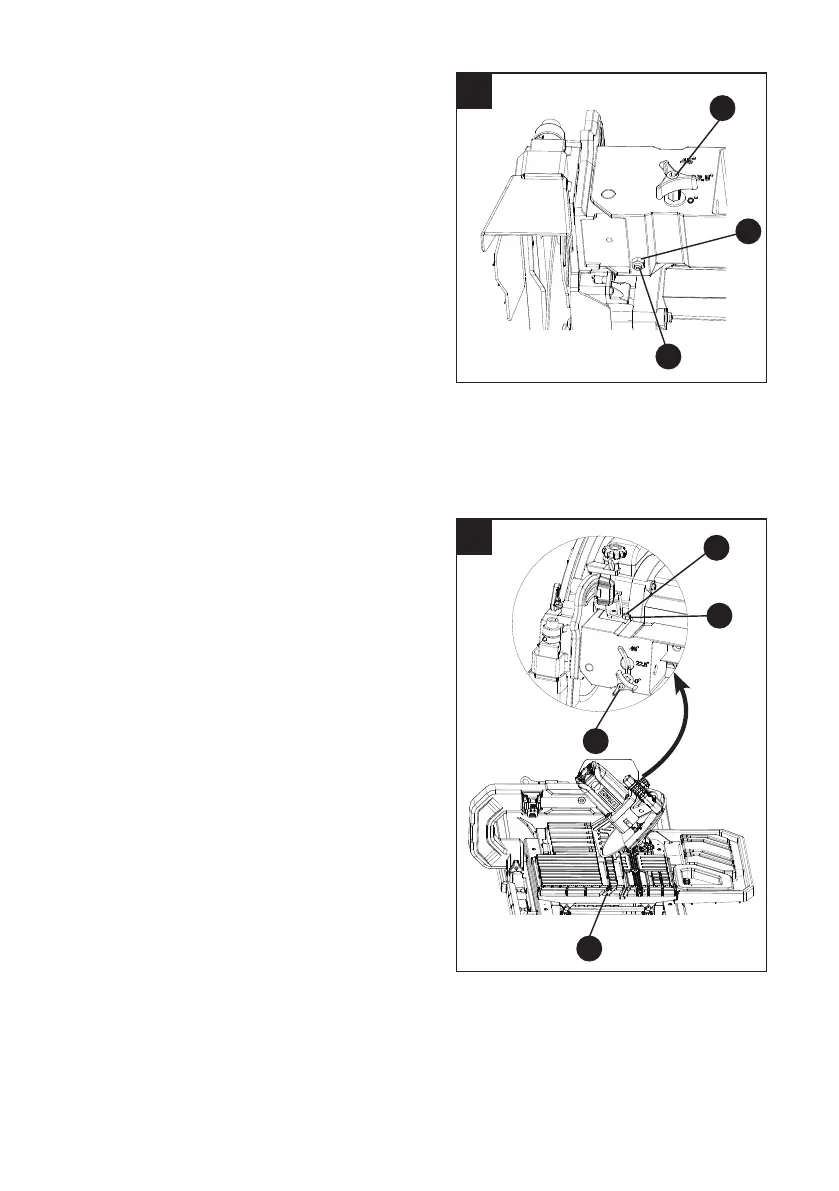

33

33

PP

4

BOTTOM VIEW

34

Adjusting the cutting wheel 90° to sliding

table (Fig. 32, 33)

● Disconnect the saw from the power source.

● Loosen the bevel lock knob (PP) and make

sure the cutting wheel is in the maximum

vertical position. Tighten the bevel lock

knob (PP).

● Place a 90° framing square on the sliding

table surface.

● If the cutting wheel is not 90° to the

groove (2-Fig. 32), loosen the lock

nut (3) with a adjustable wrench and turn

the hex bolt (4) (located under the cutting

arm assembly as shown in Fig. 33) in or

out accordingly with a 3 mm hex key until

the wheel is ush with the framing square

while moving down the center of the groove.

Tighten the lock nut (3).

● Make sure that the cutting wheel does not

touch either side of the groove (2-Fig. 32) in

the sliding table by pushing the table past

the cutting wheel.

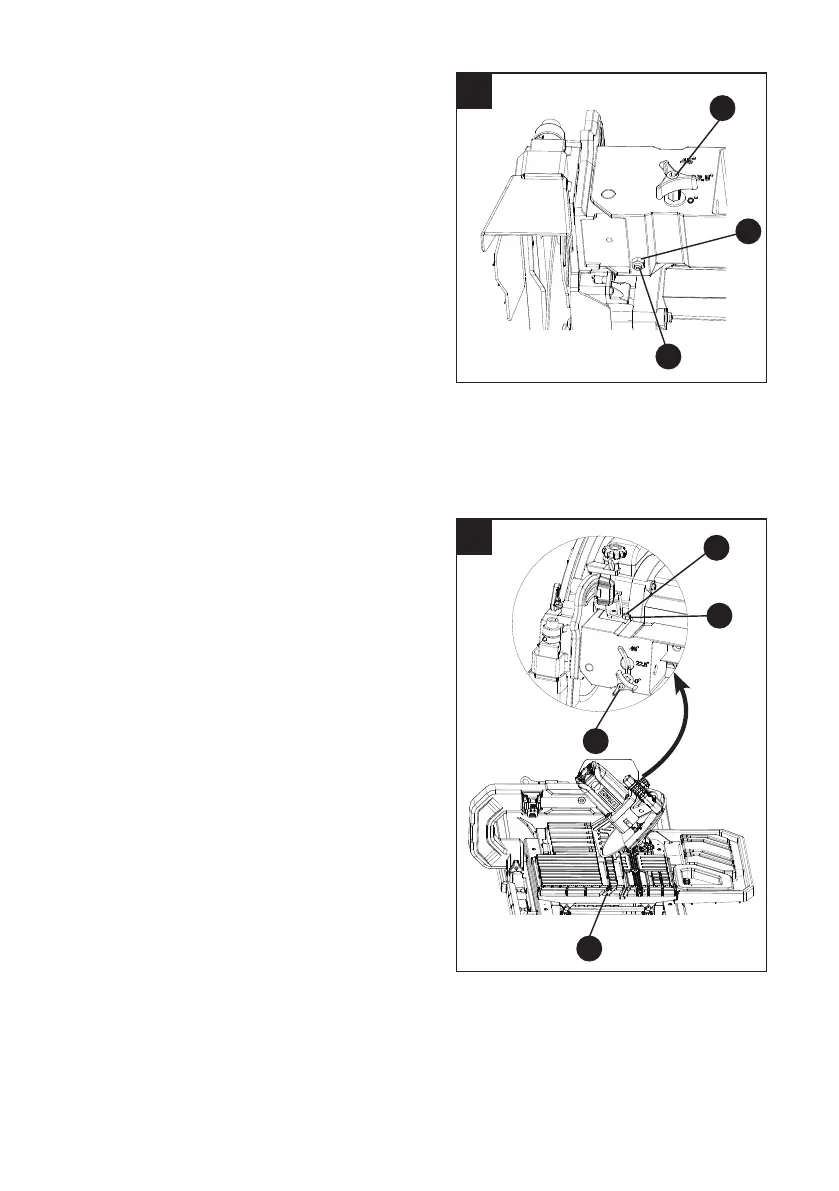

Adjusting the cutting wheel 45° to sliding

table (Fig. 34)

● Disconnect the saw from the power source.

● Loosen the bevel lock knob (PP) and move

the cutting wheel to the maximum bevel

position.

● Place the combination square to the sliding

table surface.

● If the cutting wheel is not 45° to the

groove (5), loosen the lock nut (6)

with a adjustable wrench and turn the

45° hex bolt (7) (located on top of the

cutting arm assembly as shown in

Fig. 34) in or out accordingly by using a

3 mm hex key until it is 45° to the sliding

table surface and tighten the bevel lock

knob (PP). Tighten the lock nut (6).

● Make sure that the cutting wheel does not

touch either side of the groove (5) in the

sliding table by pushing the table past the

cutting wheel.

7

6

PP

5

3

Loading...

Loading...