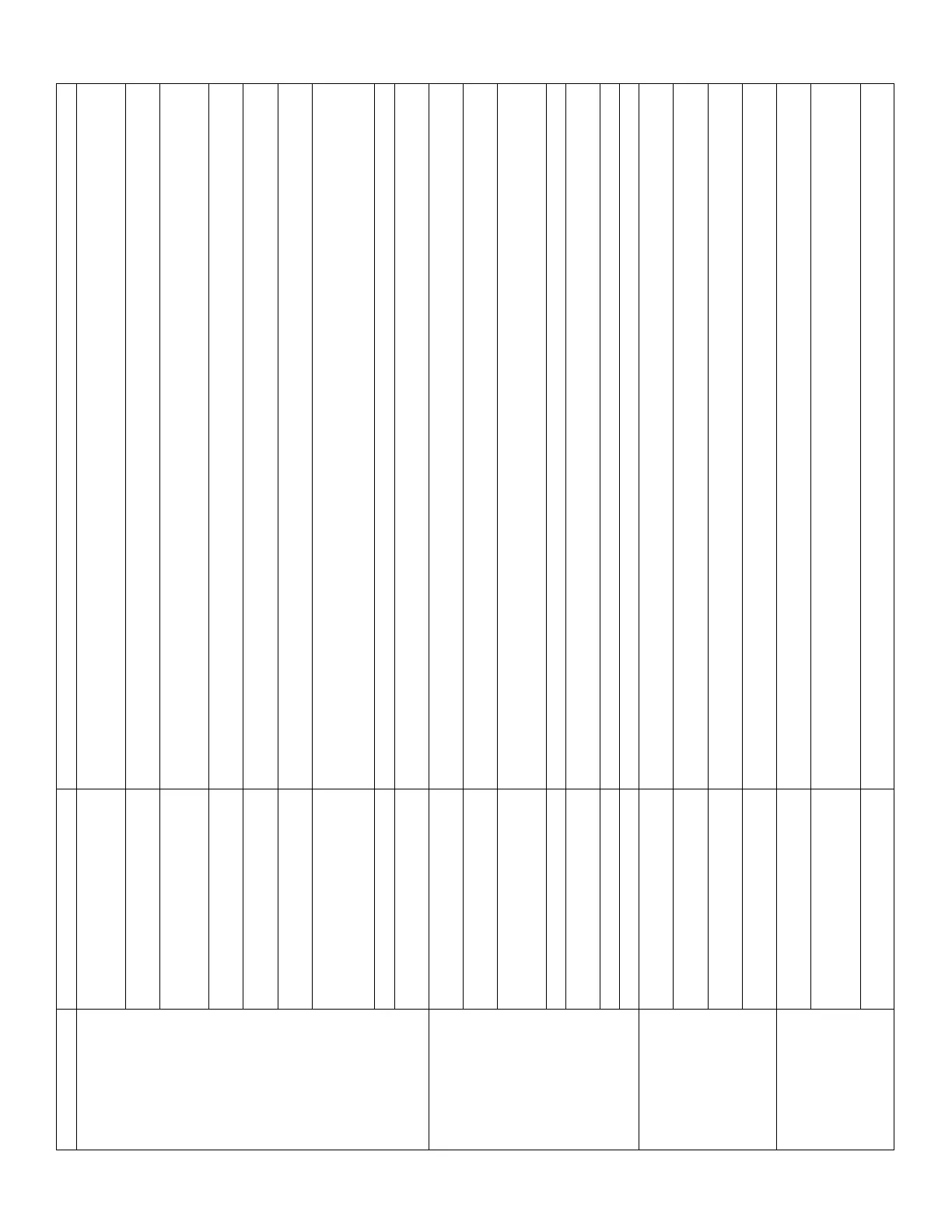

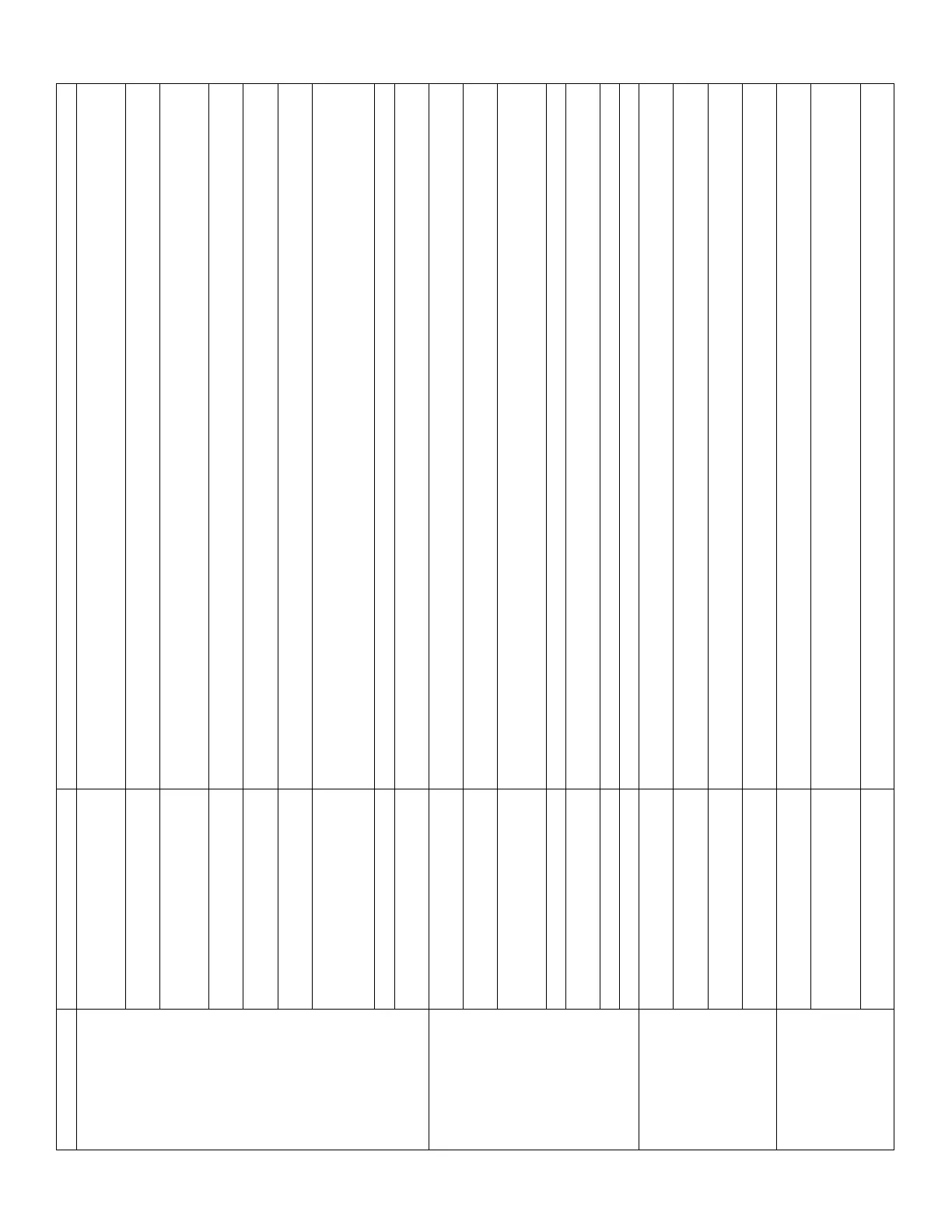

TP-6953 7/19140 Section 7 Troubleshooting

Symptom Potential Causes Troubleshooting

Start Relay Overload

Damaged or inoperative crank relay. Start Relay Overload means that the current on the Start Relay has exceeded 10A for 10ms. In systems where the 71 output

from the controller drives a pilot relay to operate the starter solenoid, the coil on the relay may be short-circuited, causing the

current draw on the 71 wire to exceed 10A.

Damaged or inoperative starter

solenoid.

In systems where the 71 wire from the controller directly drives the starter solenoid, an inoperative solenoid may draw more

than 10A. It may be sufficient to add a pilot relay to drive the starter solenoid.

Mag pickup wiring damaged. The controller requires a speed signal from a mag pickup in non-ECM applications. Without a signal from the mag pickup,

the controller does not know that the engine is turning. The w iring from the mag pickup may have been damaged to interrupt

the signal.

Mag pickup d amaged or

mal-adjusted.

If the mag pickup is damaged, misaligned or mal-adjusted, the controller will not be able to detect engine rotation and will

fault for a locked rotor condition.

Low battery charge, weak battery,

or corroded battery terminals.

If the crank relay is dropping out as soon as the starter engages, the engine will not turn, but the controller may remain

powered up throughout the event. The start relay and solenoid will make a chattering noise in this condition.

Missing, damaged, incorrect wiring

to the starter.

If the engine is not turning, Verify that the starter is receiving battery voltage to the large post on the solenoid. Verify that the

71 wire to the starter solenoid is activating when the engine is signaled to start.

Start Relay is damaged or

inoperative.

Most applications drive the starter s olenoid with a pilot relay. Verify that the pilot relay is supplied with battery voltage and

that it is activating when the 71 output from the controller turns on.

Note: The 71 wire will appear to be supplying battery voltage if all that is connected to it is a multimeter. The multimeter must

be connected across the coil of the relay while the relay is plugged in.

Starter is damaged or inoperative. If the starter is receiving the appropriate signals, but the engine is not rotating, the starter or solenoid may be inoperative.

Engine is unable to turn. In some cases, the engine may be experiencing mechanical interference or damage that will not let it turn. Verify that the

engine will turn with a breaker bar or ratchet on the bolt in the front pulley.

Over Crank

Loss of fuel prime. If the engine progresses through a full crank cycle without starting, it is entirely possible that it is not receiving fuel. Manual

priming may be required to get the engine to start.

Air in fuel. A pinhole in a fuel line or a trapped air pocket f rom assembly can inhibit an engine from starting. Manual priming and

bleeding the system may be required to clear the air pocket and start the engine.

Missing, damaged, incorrect wiring

to the fuel solenoid or ECM.

If the ECM or fuel solenoid is not powered up while cranking, the engine will not be able to start. The fuel solenoid power can

be verified with a multimeter and it should click when the engine is signaled to start. The ECM is powered if the controller is

able to sense engine speed while cranking.

ECM fault code. If the ECM has a fault, it may not permit the engine to start. Further troubleshooting will depend on the fault that is present.

Damaged or inoperative component

in the fuel system.

A fuel pump failure, pressure regulator failure, fuel solenoid failure, or electrical problem in a c ontrol system may prevent the

engine from starting. Refer to the engine service manual for expected fuel pressures and component checkout procedures.

Weak or damaged battery. A weak battery or battery with a shorted cell may result in a crank speed too slow for the engine to start.

Starter is damaged or inoperative. The engine may not be able to start if it turns too slowly. A weak starter may result in slow rotating speed.

ECM Communication

Loss

Damaged or inoperative Run Relay. The fault requires that the ECM establishes communications and then loses it. It is possible that the Run Relay is dropping

out or has an intermittent connection. Verify that the ECM is retaining power until the shutdown occurs.

Intermittent CAN wiring connection. Loose wiring w ill often vibrate on startup and cause an intermittent connection. Check connections on CAN wiring to ensure

that they are tight and all crimps are well formed and making good electrical connections.

Missing, damaged or incorrect

wiring to supply power to ECM.

The ECM communication may drop out if the power supply to the ECM is intermittent. Verify wiring through all connectors to

the ECM.

Connection of additional devices to

engine CAN.

Additional devices include CAN analysis tools, 3rd-party data logging solutions, ECM diagnostic software, etc. Any of these

devices may cause additional traffic on the CAN lines that may cause the controller to lose communication with the ECM.

Speed Sensor Fault

Engine stalled unintentionally. The engine stopped rotating without the controller telling it to stop. This could be caused by a loss of fuel, an external stop

signal, or an unannounced ECM fault.

Mag pickup wiring intermittent. On non-ECM engines, this fault may indicate that the signal from the mag pickup was lost unexpectedly (which could be

caused by bad wiring to the mag pickup).

Review the wiring to the mag pickup, checking for loose connections on terminals and crimp joints.

Mag pickup mal-adjusted. A mal-adjusted mag pickup can work intermittently, it may also provide a temperature-related signal (as parts expand). Verify

that the mag pickup is adjusted per the factory specifications.

Loading...

Loading...