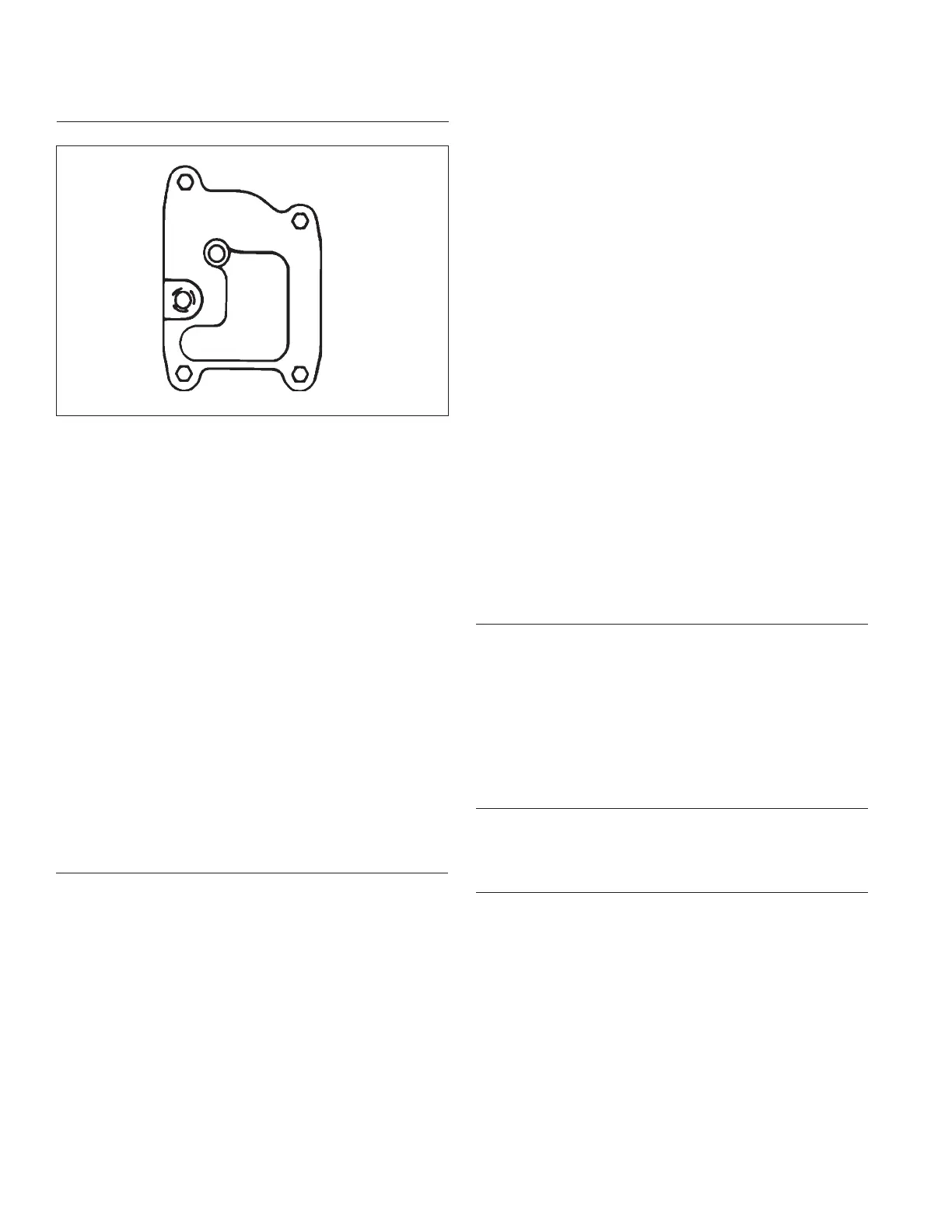

Install Breather Cover and Inner Baffl es

Breather Cover Torque Sequence

1

2

3

4

RTV sealant was used on early models between

breather cover and crankcase. A gasket with imprinted

sealant beads is now used and recommended. Install as

follows:

1. Be sure sealing surfaces of crankcase and breather

cover are clean of old gasket material or RTV

sealant. Do not scrape surfaces as this could result

in leakage.

2. Check to make sure there are no nicks or burrs on

sealing surfaces.

3. Install breather reed and breather reed retainer onto

crankcase and secure with screw. Hold assembly in

line when tightening. Torque screw to 3.9 N·m

(35 in. lb.).

4. Insert breather fi lter into position in crankcase. Make

sure no fi lter strands are on sealing surface.

5. Install new breather gasket.

6. Carefully position breather cover on crankcase.

Install fi rst two screws at positions shown and fi nger

tighten at this time.

7. Install inner baffl es using two remaining screws and

fi nger tighten. Do not torque screws at this time; they

will be tightened after blower housing and outer

baffl es are installed.

Install Blower Housing and Outer Baffl es

NOTE: Do not completely tighten screws until all items

are installed to allow shifting for hole alignment.

1. Connect plug to key switch in blower housing (if

equipped).

2. Slide blower housing into position over front edge of

inner baffl es. Start a few screws to hold it in place.

On two-barrel carburetor models, lift debris shield up

above mounting surface, as blower housing is

installed. Make sure ground lead, fuel solenoid lead,

and oil pressure switch leads are accessible and in

proper position.

3. Position outer baffl es and loosely start mounting

screws. M6 screws go into back of cylinders. Short

M5 screws go into lower holes closest to blower

housing. Short screw on oil fi lter side is also used to

mount wire harness clip. Be sure any wire harnesses

or leads are routed out through proper off sets or

notches, so they will not be pinched between blower

housing and baffl es.

4. If rectifi er-regulator was not removed, attach ground

wire or metal grounding bracket for rectifi er-

regulator, using silver colored screw and washer, to

lower blower housing hole.

5. Tighten all shrouding fasteners. Torque blower

housing screws to 6.2 N·m (55 in. lb.) in a new hole,

or to 4.0 N·m (35 in. lb.) in a used hole. Torque

shorter M5 side baffl e screws to 4.0 N·m (35 in. lb.).

Torque upper M5 side baffl e screws (into cylinder

head) to 6.2 N·m (55 in. lb.) in a new hole, or to 4.0

N·m (35 in. lb.) in a used hole. Torque two rear M6

baffl e mounting screws to 10.7 N·m (95 in. lb.) in a

new hole, or to 7.3 N·m (65 in. lb.) in a used hole.

6. If an overlapping style fl ywheel screen is used,

attach it to supports or fl ywheel. For a metal fl ywheel

screen, apply Loctite

®

242

®

to screw threads (M6)

and torque to 9.9 N·m (88 in. lb.). Torque plastic

screen mounting screws (M4) to 2.2 N·m (20 in. lb.).

7. Torque breather cover screws to 11.3 N·m (100 in.

lb.) into new holes or 7.3 N·m (65 in. lb.) into used

holes in sequence shown. Note fi rst screw is torqued

a second time.

Reconnect Rectifi er-Regulator

1. Install rectifi er-regulator in blower housing, if

removed previously, then connect rectifi er-regulator

ground lead with washer and silver screw through

eyelet as shown. If a grounding bracket is used,

secure with lower mounting screw and washer,

against outer side of rectifi er-regulator.

2. Install B+ terminal/lead into center position of

rectifi er-regulator plug and connect plug to rectifi er-

regulator.

SMART-SPARK

™

Module

On engines with SMART-SPARK

™

, reinstall SAM module

to blower housing or cylinder baffl e. Do not overtighten

retaining screws.

Install Electric Starter Motor

NOTE: If engine uses a side mount muffl er on starter

side, be sure to tie wires close to starter to avoid

contact with hot exhaust parts.

1. Install starter motor using two screws. Some inertia-

drive starters have a pinion cover and spacers on

starter bolts.

2. Torque screws to 15.3 N·m (135 in. lb.).

3. On models with a solenoid shift starter, connect

leads to solenoid.

Reassembly

116 24 690 06 Rev. PKohlerEngines.com

Loading...

Loading...