5.4

Section 5

Fuel System and Governor

High Altitude Operation

Operating the engine with the wrong engine

confi guration at a given altitude may increase

its emissions and decrease fuel effi ciency and

performance. To ensure correct engine operation

at altitudes above 1219 meters (4000 ), it may be

necessary to have an authorized Kohler dealer install

a special high altitude jet kit in the carburetor. If a

high altitude kit has been installed, the engine must

be reconverted to the original jet size, before it is

operated at lower altitudes, or overheating and engine

damage can result.

To obtain high altitude kit information or locate a

dealer near you, call 1-800-544-2444 to fi nd the names

of the nearest Kohler Co. Service Centers or, access

our web site at: www.kohlerengines.com and click

on the Service & Dealer Locator located in the upper

right hand corner. The service center will need your

engine specifi cation number which is found on your

Engine ID Label.

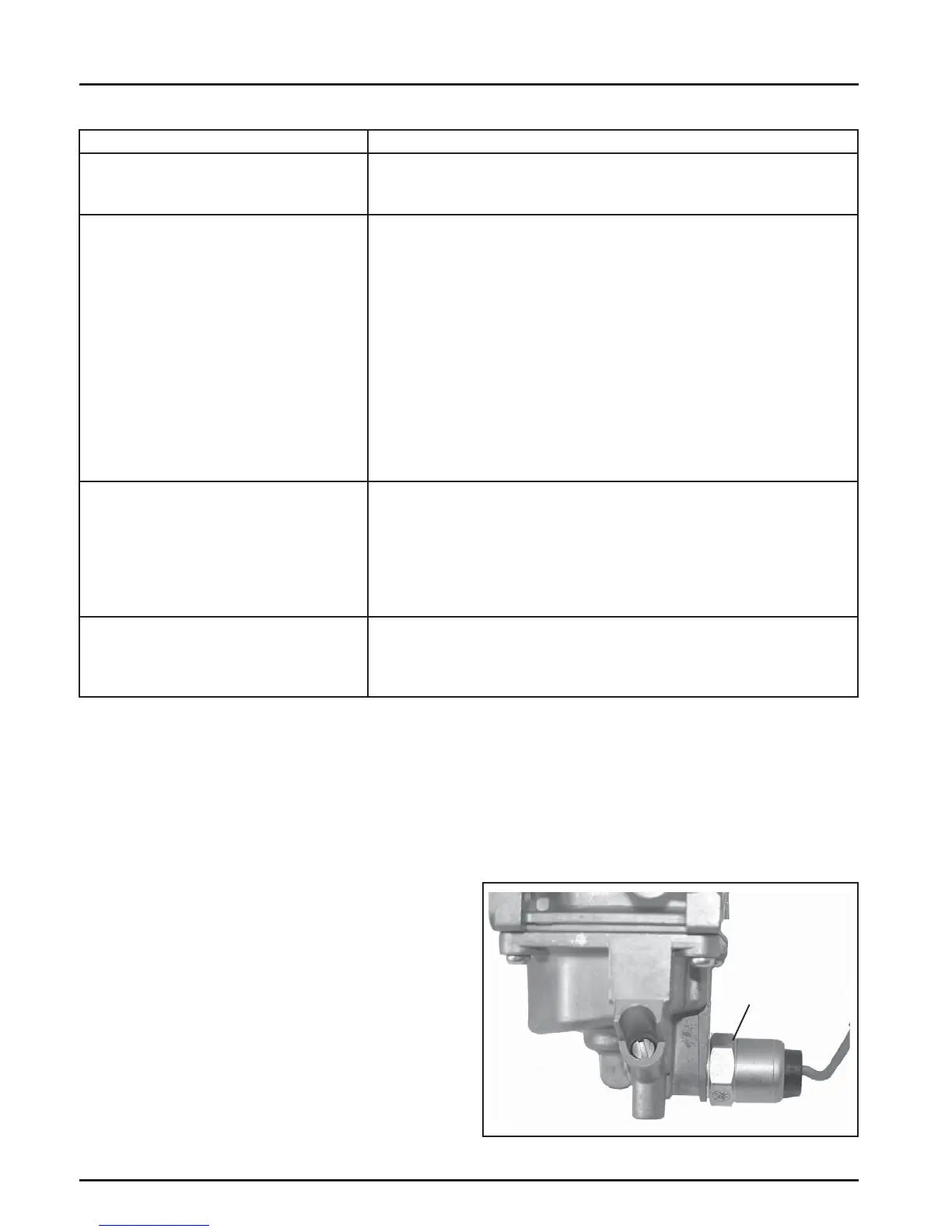

Fuel Shut-off Solenoid

Most carburetors are equipped with a fuel shut-off

solenoid. The solenoid is a ached to the fuel bowl. See

Figure 5-4. The solenoid has a spring-loaded pin that

retracts when 12 volts is applied to the lead, allowing

fuel fl ow to the main jets. When current is removed

the pin extends blocking the fuel fl ow.

Troubleshooting – Carburetor Related Causes

Fuel Shut-Off

Solenoid

Figure 5-4. Fuel Shut-off Solenoid.

Condition Possible Cause/Probable Remedy

1. Engine starts hard, runs roughly,

or stalls at idle speed.

1. Low idle fuel mixture (some models)/speed improperly

adjusted. Adjust the low idle speed tab, then adjust the low idle

fuel needle.

2. Engine runs rich (indicated by

black, sooty exhaust smoke,

misfi ring, loss of speed and power,

governor hunting, or excessive

thro le opening).

2a. Clogged air cleaner. Clean or replace.

b. Choke partially closed during operation. Check the choke lever/

linkage to ensure choke is operating properly.

c. Low idle fuel mixture is improperly adjusted. Adjust low idle

fuel needle (some models).

d. Float level is set too high. Adjust fl oat according to Float

Replacement Procedure.

e. Dirt under the fuel inlet needle. Remove needle; clean needle

and seat and blow with compressed air.

f. Bowl vent or air bleeds plugged. Remove low idle fuel adjusting

needle. Clean vent, ports, and air bleeds. Blow out all passages

with compressed air.

g. Leaky, cracked or damaged fl oat. Submerge fl oat to check for

leaks.

3. Engine runs lean (indicated by

misfi ring, loss of speed and power,

governor hunting, or excessive

thro le opening).

3a. Low idle fuel mixture is improperly adjusted. Adjust low idle

fuel needle (some models).

b. Float level is set too low. Adjust fl oat according to Float

Replacement Procedure.

c. Idle holes plugged; dirt in fuel delivery channels. Remove low

idle fuel adjusting needle. Clean main fuel jet and all passages;

blow out with compressed air.

4. Fuel leaks from carburetor. 4a. Float level set too high. See Remedy 2d.

b. Dirt under fuel inlet needle. See Remedy 2e.

c. Bowl vents plugged. Blow out with compressed air.

d. Carburetor bowl gasket leaks. Replace gasket.

Loading...

Loading...