7.3

Section 7

Electrical System and Components

7

Battery

General

A 12-volt ba ery with 400 cold cranking amps (cca) is

generally recommended for starting in all conditions.

A smaller capacity ba ery is o en suffi cient if an

application is started only in warmer temperatures.

Refer to the following table for minimum capacities

based on anticipated ambient temperatures. The

actual cold cranking requirement depends on engine

size, application, and starting temperatures. The

cranking requirements increase as temperatures

decrease and ba ery capacity shrinks. Refer also to the

operating instructions of the equipment this engine

powers for specifi c ba ery requirements.

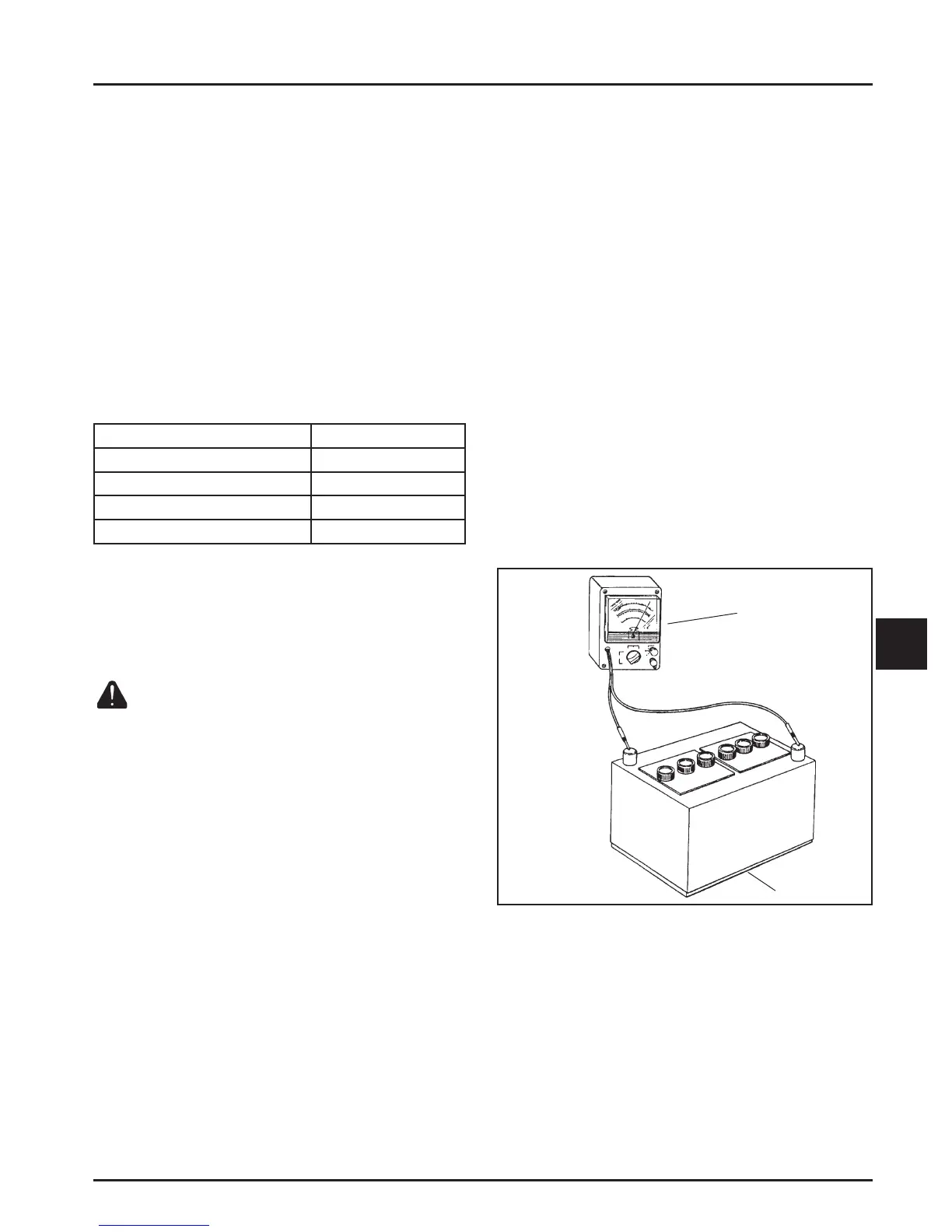

Battery Size Recommendations

Temperature Battery Required

Above 32°F (0°C) 300 cca minimum

0°F to 32°F (-18°C to 0°C) 300 cca minimum

-5°F to 0°F (-21°C to -18°C) 300 cca minimum

-10°F (-23°C) or below 400 cca minimum

If the ba ery charge is insuffi cient to turn over the

engine, recharge the ba ery.

Battery Maintenance

Regular maintenance is necessary to prolong ba ery

life.

WARNING: Explosive Gas!

Ba eries produce explosive hydrogen gas while being

charged. To prevent a fi re or explosion, charge ba eries only

in well ventilated areas. Keep sources of ignition away from

the ba ery at all times. Keep ba eries out of the reach of

children. Remove all jewelry when servicing ba eries.

Before disconnecting the negative (-) ground cable, make

sure all switches are OFF. If ON, a spark will occur at the

ground cable terminal which could cause an explosion if

hydrogen gas or gasoline vapors are present.

1. Regularly check the level of electrolyte. Add

distilled water as necessary to maintain the

recommended level.

NOTE: Do not overfi ll the ba ery. Poor performance

or early failure due to loss of electrolyte will

result.

2. Keep the cables, terminals, and external surfaces

of the ba ery clean. A build-up of corrosive acid

or grime on the external surfaces can cause the

ba ery to self-discharge. Self-discharge occurs

rapidly when moisture is present.

3. Wash the cables, terminals, and external surfaces

with a mild baking soda and water solution.

Rinse thoroughly with clear water.

NOTE: Do not allow the baking soda solution

to enter the cells as this will destroy the

electrolyte.

Battery Test

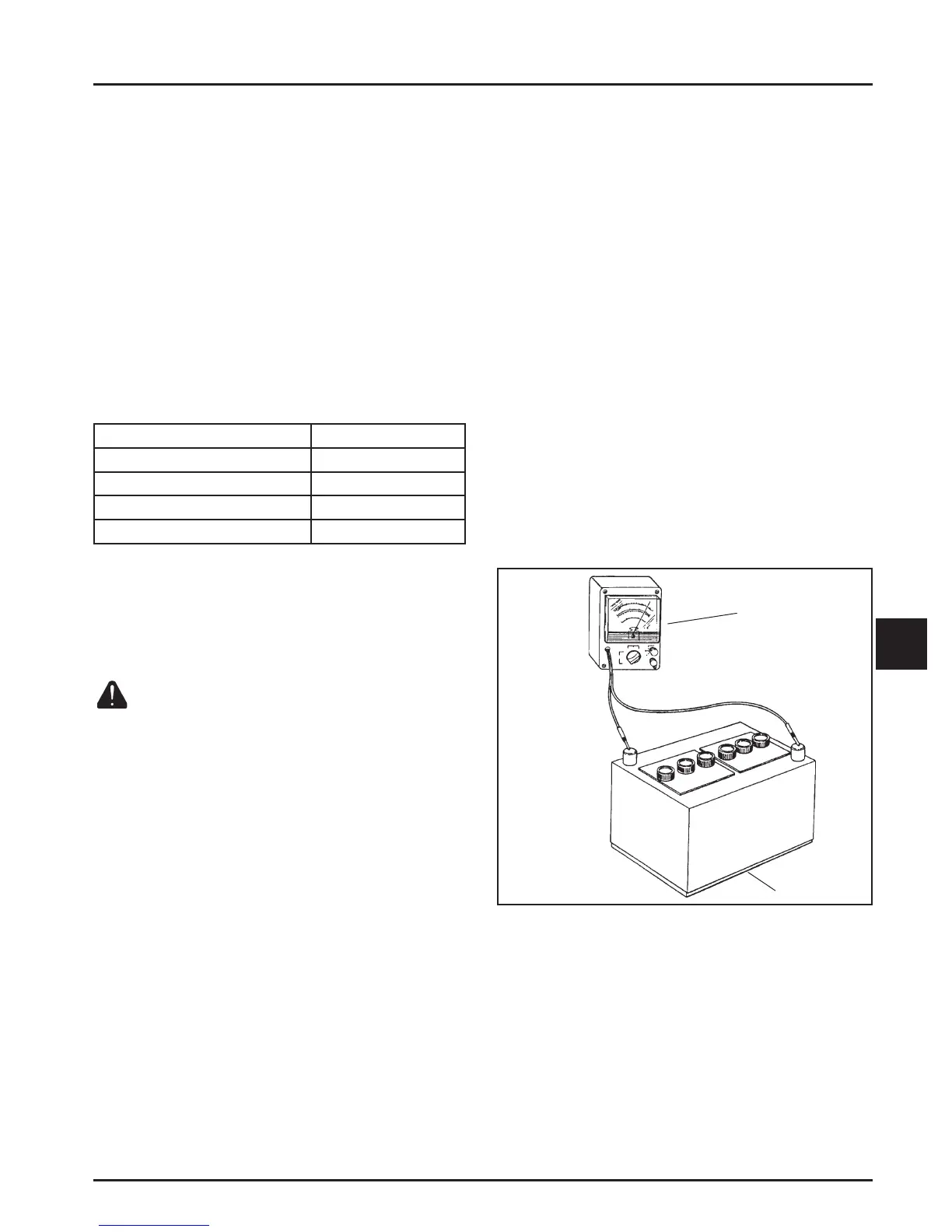

To test the ba ery, you will need a DC voltmeter.

Perform the following steps (See Figure 7-2):

1. Connect the voltmeter across the ba ery

terminals.

2. Crank the engine. If the ba ery drops below 9

volts while cranking, the ba ery is too small,

discharged, or faulty.

DC Voltmeter

Battery

Figure 7-2. Battery Voltage Test.

Loading...

Loading...