10.4

Section 10

Internal Components

Hard starting, or loss of power accompanied by high

fuel consumption may be symptoms of faulty valves.

Although these symptoms could also be attributed to

worn rings, remove and check the valves first. After

removal, clean the valve heads, faces, and stems with a

power wire brush.

Then, carefully inspect each valve for defects such as

warped head, excessive corrosion, or worn stem end.

Replace valves found to be in bad condition.

Valve Guides

If a valve guide is worn beyond specifications, it will

not guide the valve in a straight line. This may result

in burnt valve faces or seats, loss of compression, and

excessive oil consumption.

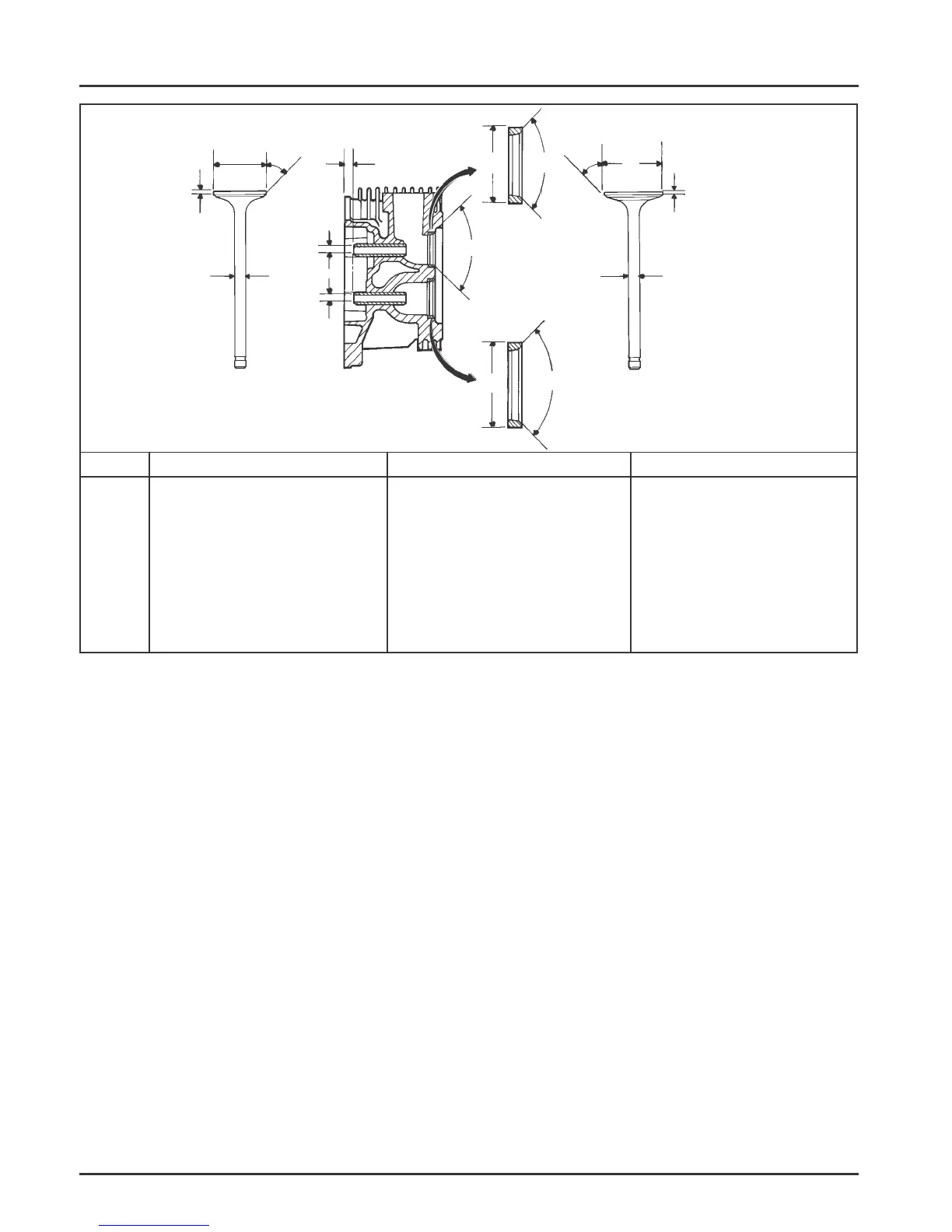

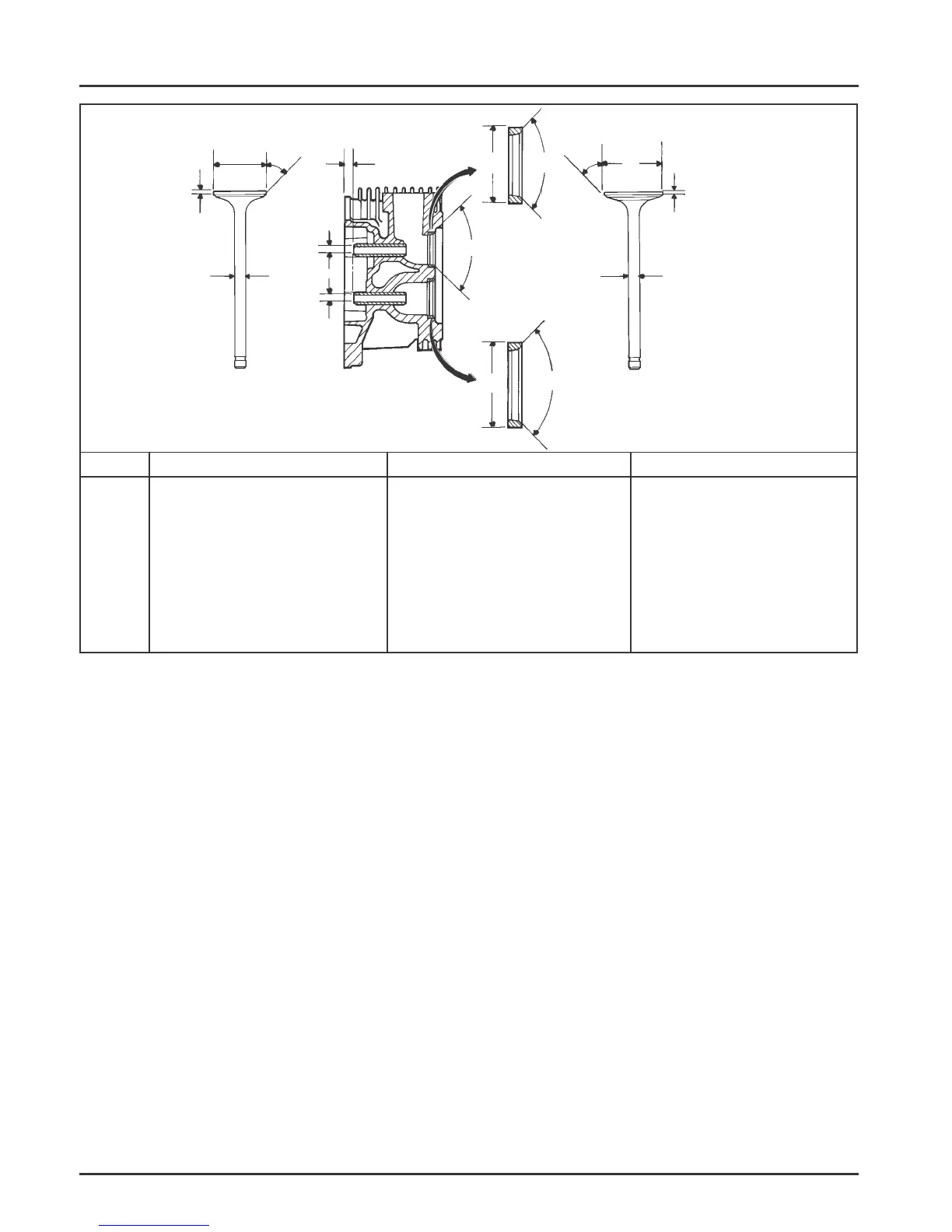

Dimension

Intake

Exhaust

A

B

C

D

E

F

G

H

Seat Angle

Insert O.D.

Guide Depth

Guide I.D.

Valve Head Diameter

Valve Face Angle

Valve Margin (Min.)

Valve Stem Diameter

89°

37.987/38.013 mm

6.5 mm

7.033/7.058 mm

35.63/35.37 mm

45°

1.5 mm

6.982/7.000 mm

89°

34.013/33.987 mm

6.5 mm

7.033/7.058 mm

31.63/31.37 mm

45°

1.5 mm

6.970/6.988 mm

To check valve guide to valve stem clearance,

thoroughly clean the valve guide and, using a split-

ball gauge, measure the inside diameter. Then, using

an outside micrometer, measure the diameter of the

valve stem at several points on the stem where it

moves in the valve guide. Use the largest stem

diameter to calculate the clearance. If the clearance

exceeds 7.134 mm (0.2809 in.) on intake or 7.159 mm

(0.2819 in.) on exhaust valve, determine whether the

valve stem or the guide is responsible for the excessive

clearance.

If the valve stem diameter is within specifications,

then recondition the valve guide.

Reconditioning Valve Guide

The valve guides in the cylinder head are not

removable. Use a 0.25 mm (0.010 in.) O/S reamer (See

Section 2).

Intake Valve

C

D

D

H

G

Exhaust Valve

E

F

Exhaust

Insert

Intake

Insert

G

H

A

A

B

B

A

F

E

Figure 10-3. Valve Details.

Loading...

Loading...