5A.11

Section 5A

LPG Fuel Systems

5A

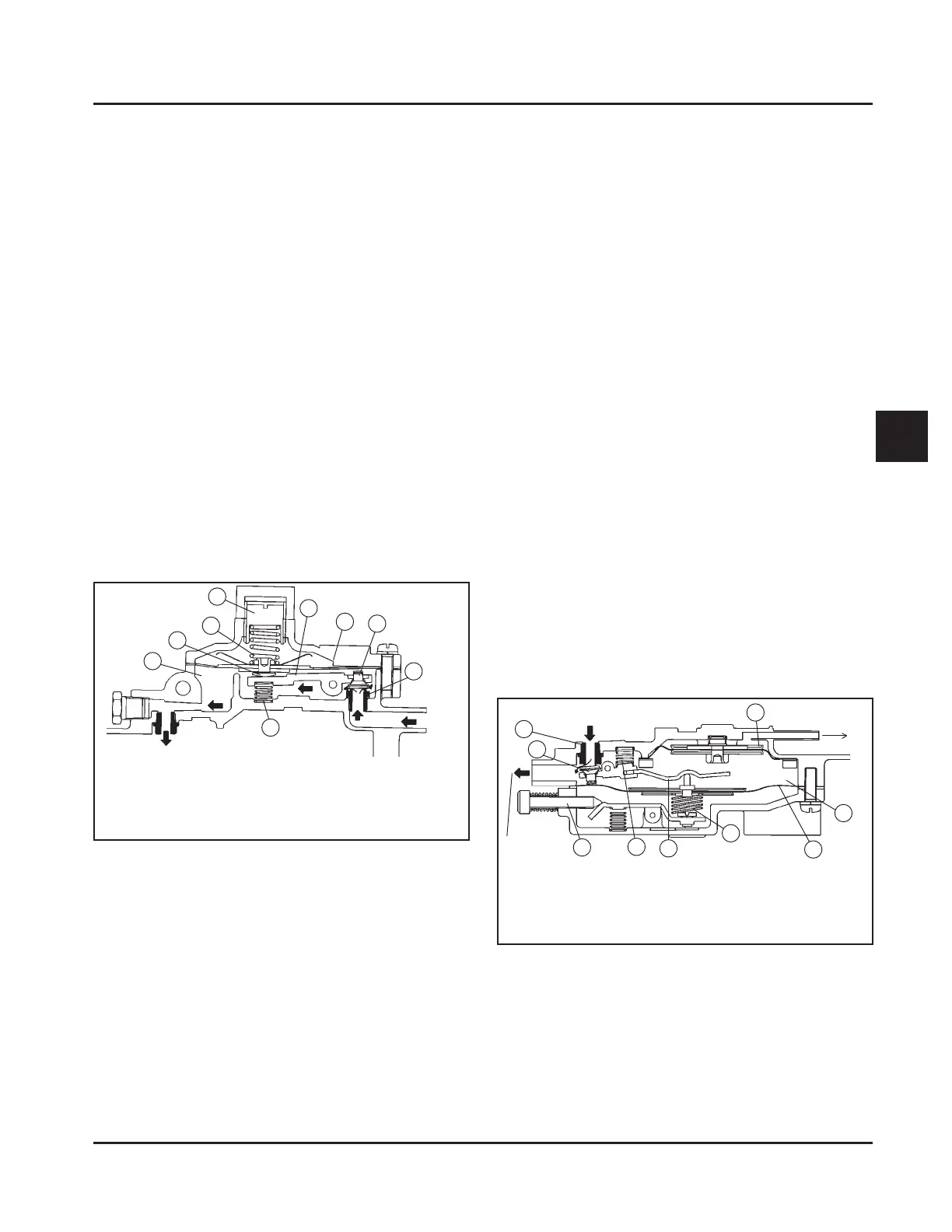

Nikki Regulator Primary Chamber

(See Figure 5A-21)

The primary chamber reduces the high pressure fuel

flow from the tank and vaporizer down to

approximately 4 psi. Fuel flowing from the vaporizer

enters the inlet of the regulator under approximately

76 kPa (11 psi) of pressure. There it is delivered to the

primary chamber (3) through the clearance between

the primary valve (1) and valve seat (2). As fuel

continues to flow and the primary chamber

approaches 29 kPa (4 psi), the primary diaphragm (4)

overcomes the tension of the diaphragm spring (5). As

the diaphragm (4) and contact button (6) move up, the

primary lever spring (8) pushes the primary lever (7)

up, in turn closing the primary valve (1) and stopping

the flow of fuel. As fuel is consumed and the pressure

in the primary chamber drops below 29 kPa (4 psi), the

diaphragm spring (5) tension will be greater than the

fuel pressure, causing the primary diaphragm (4) to be

pushed down. This causes the contact button (6), to

push the primary lever (7) down, in turn opening the

primary valve (1) and admitting more fuel. In this

manner, the pressure within the primary chamber is

maintained at a relatively constant 29 kPa (4 psi).

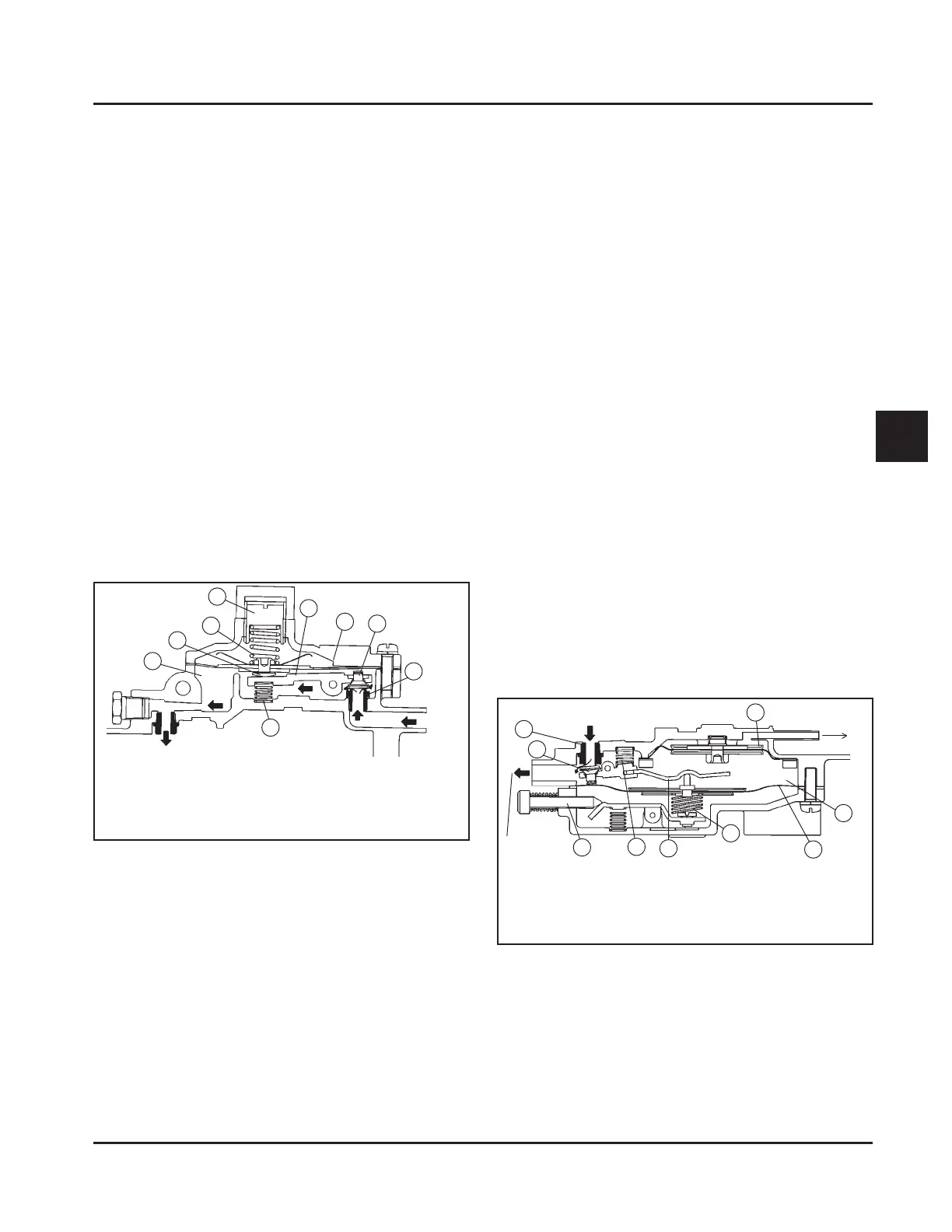

Nikki Regulator Secondary Chamber

(See Figure 5A-22)

The secondary chamber further reduces the fuel

pressure from the 29 kPa (4 psi) of the primary

chamber to near 0 kPa (0 psi) pressure, to prevent

excessive fuel flow to the carburetor. Fuel enters the

secondary chamber (13) through the clearance

between the secondary valve (11) and the valve seat

(12). While the engine is operating, and fuel is being

drawn from the secondary chamber, the secondary

diaphragm (14) is raised by atmospheric pressure,

simultaneously lifting the secondary valve lever (16),

opening the secondary valve (11), allowing fuel to

flow. When the engine is running at idle, there may

not be enough vacuum created in the carburetor

venturi to overcome the tension of the secondary

diaphragm spring (15), and the secondary diaphragm

cannot open the valve. Under those conditions, the

idle adjusting screw (18), and balance spring (19) are

used to apply just enough pressure on the diaphragm

(14) to maintain sufficient fuel flow for idle operation.

The vacuum lock-off mechanism is located in the

secondary chamber. When the engine is running,

manifold vacuum above the diaphragm (17) draws it

up, so the secondary valve can function normally.

When the engine is stopped, manifold vacuum is

terminated, and the diaphragm relaxes and pushes

down on the secondary valve lever, preventing any

fuel flow or leakage through the regulator.

11. Secondary Valve 16. Secondary Valve Lever

12. Secondary Valve Seat 17. Vacuum Lock-Off

13. Secondary Chamber Diaphragm

14. Secondary Diaphragm 18. Idle Adjust Screw

15. Secondary Diaphragm Spring 19. Balance Spring

From Primary

Chamber

13

14

19

16

15

To

Carburetor

11

To Intake

Manifold

17

18

12

Figure 5A-22. Secondary Chamber.

Figure 5A-21. Primary Chamber.

1. Primary Valve 6. Contact Button

2. Primary Valve Seat 7. Primary Valve Lever

3. Primary Chamber 8. Primary Lever Spring

4. Primary Diaphragm 9. Primary Pressure

5. Primary Diaphragm Spring Adjustment

To Secondary Chamber

8

3

6

5

9

7

4

1

2

Fuel

Inlet

Loading...

Loading...