70

Disassembly/Inspection and Service

KohlerEngines.com 24 690 06 Rev. C

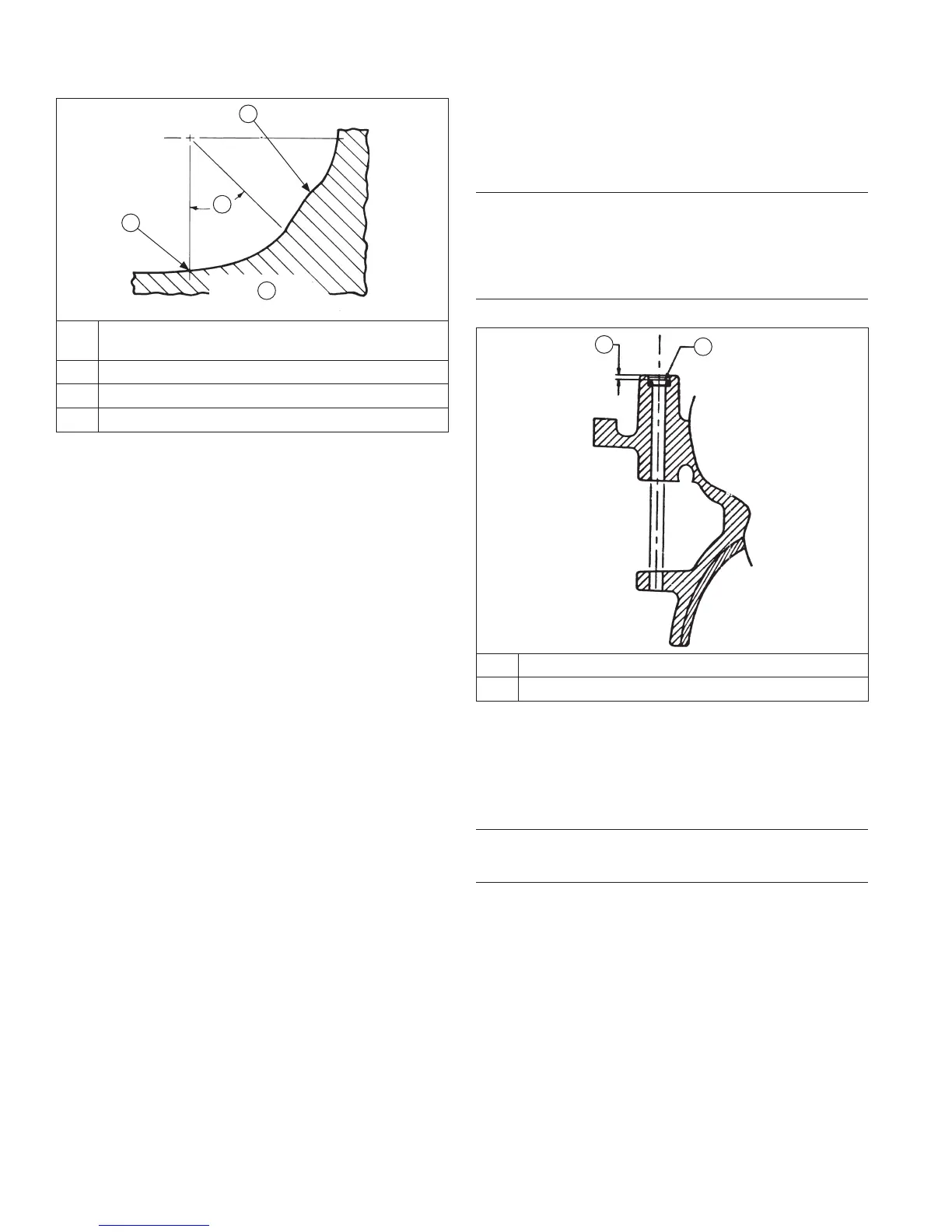

E

G

F

H

E

Fillet Must Blend Smoothly with Bearing Journal

Surface

F High Point from Fillet Intersections

G 45° Minimum

H This Fillet Area Must Be Completely Smooth

NOTE: If crankpin is reground, visually check to ensure

fi llet blends smoothly with crankpin surface.

Carefully pull crankshaft from crankcase. Note thrust

washers and shims if used.

Inspect gear teeth of crankshaft. If teeth are badly worn,

chipped, or some are missing, replacement of crankshaft

will be necessary.

Inspect crankshaft bearing surfaces for scoring,

grooving, etc. Some engines have bearing inserts in

crankshaft bore of closure plate and/or crankcase.

Do not replace bearings unless they show signs of

damage or are out of running clearance specifi cations. If

crankshaft turns easily and noiselessly, and there is no

evidence of scoring, grooving, etc., on races or bearing

surfaces, bearings can be reused.

Inspect crankshaft keyways. If they are worn or chipped,

replacement of crankshaft will be necessary.

Inspect crankpin for score marks or metallic pickup.

Slight score marks can be cleaned with crocus cloth

soaked in oil. If wear limits, as stated in Specifi cations

and Tolerances are exceeded, it will be necessary to

either replace crankshaft or regrind crankpin to 0.25 mm

(0.010 in.) undersize. If reground, a 0.25 mm (0.010 in.)

undersize connecting rod (big end) must then be used to

achieve proper running clearance. Measure crankpin for

size, taper, and out-of-round.

Connecting rod journal can be ground one size under.

When grinding a crankshaft, grinding stone deposits

can get caught in oil passages, which could cause

severe engine damage. Removing crankpin plug when

crankshaft is ground provides easy access for removing

any grinding deposits collected in oil passages.

Use following procedure to remove and replace plug.

Procedure to Remove Crankshaft Plug:

1. Drill a 3/16" hole through plug in crankshaft.

2. Thread a 3/4" or 1" long self-tapping screw with a fl at

washer into drilled hole. Flat washer must be large

enough to seat against shoulder of plug bore.

3. Tighten self-tapping screw until it draws plug out of

crankshaft.

Procedure to Install New Plug:

Use 1 single cylinder camshaft pin as a driver and tap

plug into plug bore until it seats at bottom of bore. Make

sure plug is tapped in evenly to prevent leakage.

Remove Governor Cross Shaft

1. Remove hitch pin and plain washer, or retainer and

nylon washer from governor cross shaft.

2. Pull cross shaft with small washer out through inside

of crankcase.

Governor Cross Shaft Oil Seal

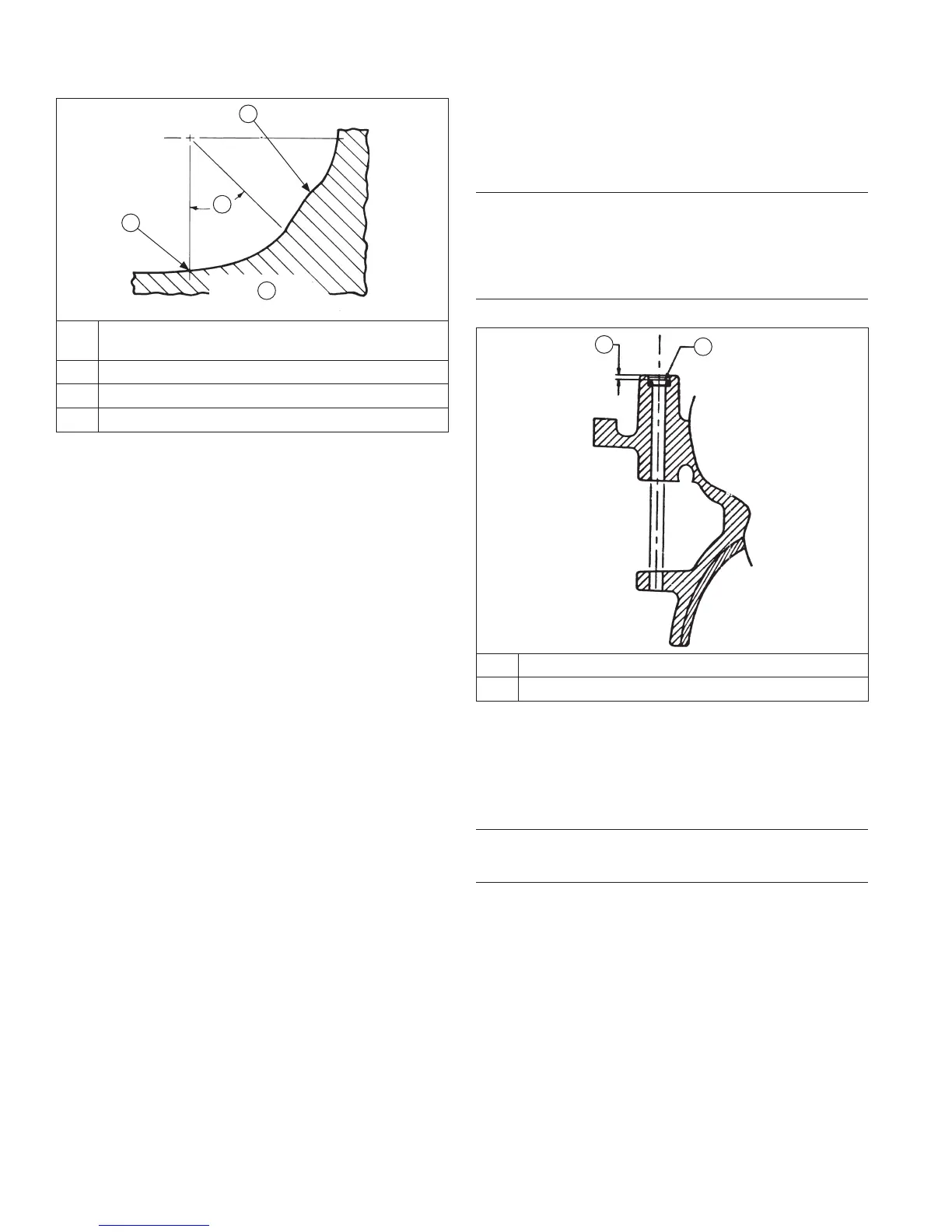

Cross Shaft Oil Seal Details

B

A

A 2.0 mm (0.0787 in.)

B Governor Cross Shaft Seal

If governor cross shaft seal is damaged and/or leaks,

replace it using following procedure.

Remove oil seal from crankcase and replace it with a

new one. Install new seal to depth shown using a seal

installer.

Remove Flywheel End Oil Seal

Remove oil seal from crankcase.

Crankcase

Inspection and Service

Check all gasket surfaces to make sure they are free of

gasket fragments. Gasket surfaces must also be free of

deep scratches or nicks.

Inspect main bearing (if equipped) for wear or damage.

Replace crankcase using a miniblock or short block as

required.

Check cylinder bore wall for scoring. In severe cases,

unburned fuel can cause scuffi ng and scoring of cylinder

wall. It washes necessary lubricating oils off piston and

cylinder wall. As raw fuel seeps down cylinder wall,

piston rings make metal to metal contact with wall.

Scoring of cylinder wall can also be caused by localized

hot spots resulting from blocked cooling fi ns or from

inadequate or contaminated lubrication.

Loading...

Loading...