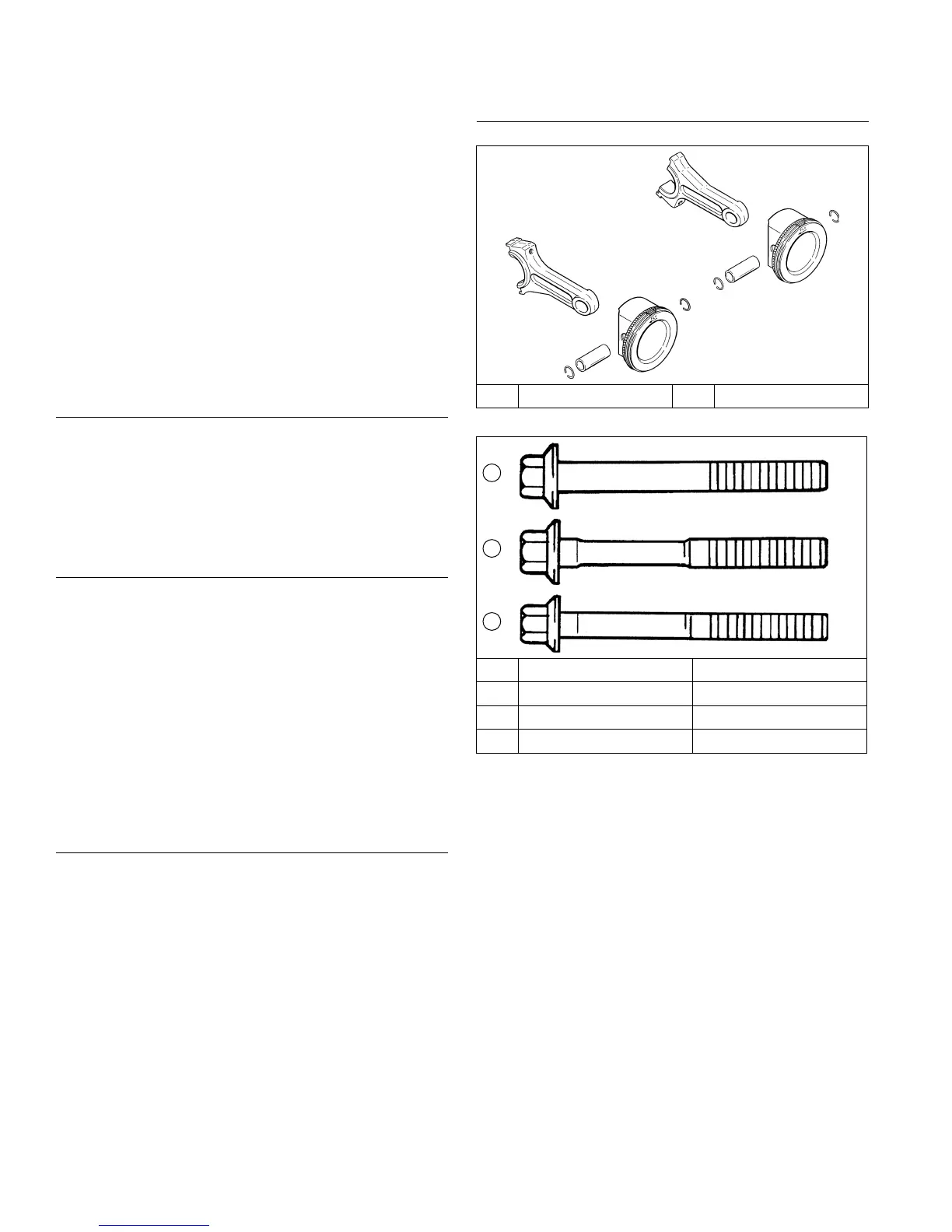

Install Connecting Rods with Pistons and Rings

Piston and Connecting Rod Details

B

A

A Cylinder 1 B Cylinder 2

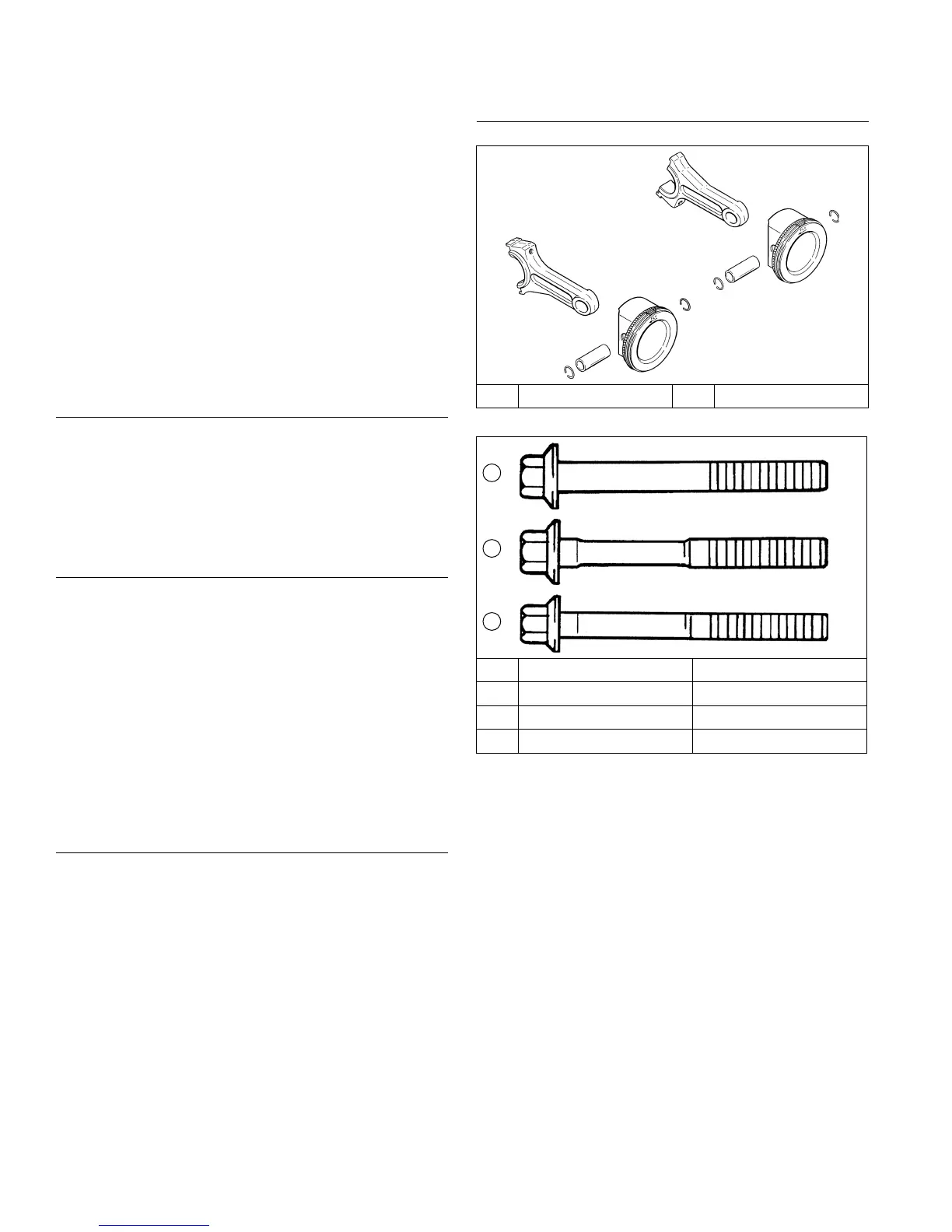

Connecting Rod Bolt Details

A

B

C

Type Torque

A 8 mm Straight Shank 22.7 N·m (200 in. lb.)

B 8 mm Step-Down 14.7 N·m (130 in. lb.)

C 6 mm Straight Shank 11.3 N·m (100 in. lb.)

NOTE: Cylinders are numbered on crankcase. Make

sure to install piston, connecting rod, and end

cap into its appropriate cylinder bore as

previously marked at disassembly. Do not mix

end caps and connecting rods.

NOTE: Proper orientation of piston/connecting rod

assemblies inside engine is extremely important.

Improper orientation can cause extensive wear

or damage. Be certain pistons and connecting

rods are assembled exactly as shown.

NOTE: Align chamfer of connecting rod with chamfer of

its mating end cap. When installed, at faces of

connecting rods should face each other. Faces

with raised rib should be toward outside.

1. If piston rings were removed, see Disassembly/

Inspection and Service procedure to install new

rings.

2. Lubricate cylinder bore, piston, and piston rings with

engine oil. Compress rings using a piston ring

compressor.

3. Lubricate crankshaft journals and connecting rod

bearing surfaces with engine oil.

NOTE: Make sure engine is assembled using all

specied torque values, tightening sequences,

and clearances. Failure to observe specications

could cause severe engine wear or damage.

Always use new gaskets. Apply a small amount

of oil to threads of critical fasteners before

assembly, unless a sealant or Loctite

®

is

specied or preapplied.

Make sure all traces of any cleaner are removed before

engine is assembled and placed into operation. Even

small amounts of these cleaners can quickly break down

lubricating properties of engine oil.

Check oil pan, crankcase, cylinder heads, and valve

covers to be certain that all old sealing material has

been removed. Use gasket remover, lacquer thinner, or

paint remover to remove any remaining traces. Clean

surfaces with isopropyl alcohol, acetone, lacquer thinner,

or electrical contact cleaner.

Install Flywheel End Oil Seal

1. Make sure seal bore of crankcase is clean and free

of any nicks or burrs.

2. Apply a light coat of engine oil to outside diameter of

oil seal.

3. Drive oil seal into crankcase using a seal driver.

Make sure oil seal is installed straight and true in

bore and tool bottoms against crankcase.

Install Governor Cross Shaft

1. Lubricate governor cross shaft bearing surfaces in

crankcase with engine oil.

2. Slide small lower washer onto governor cross shaft

and install cross shaft from inside of crankcase.

3. 6 mm governor shaft: Install plain washer and then

insert hitch pin into smaller, lower hole of governor

cross shaft.

8 mm governor shaft: Install nylon washer onto

governor cross shaft, then start push-on retaining

ring. Hold cross shaft up in position, place a 0.50

mm (0.020 in.) feeler gauge on top of nylon washer,

and push retaining ring down shaft to secure.

Remove feeler gauge, which will have established

proper end play.

Install Crankshaft

Carefully slide ywheel end of crankshaft through main

bearing in crankcase.

Reassembly

76

24 690 07 Rev. HKohlerEngines.com

Loading...

Loading...