Install Ignition Modules

1. Rotate ywheel to position magnet away from

ignition module bosses.

2. On engines equipped with SMART-SPARK

™,

both

modules are installed similarly with tabs out.

On engines not equipped with SMART-SPARK

™

modules are installed with spark plug lead wire from

module always away from cylinder. On cylinder 1,

single kill tab should be towards you. On cylinder 2,

single kill tab should be away from you (in).

3. Install each ignition module to crankcase bosses

with screws (hex ange or allen head, based on

model). Slide modules up as far away from ywheel

as possible and snug screws to hold them in that

position.

4. Rotate ywheel to position magnet directly under

one ignition module.

5. Insert a 0.30 mm (0.012 in.) at feeler gauge

between magnet and ignition module. Loosen

screws enough to allow magnet to pull module

against feeler gauge.

6. Torque screws to 4.0-6.2 N·m (35-55 in. lb.).

7. Repeat steps 4 through 6 for other ignition module.

8. Rotate ywheel back and forth checking for

clearance between magnet and ignition modules.

Make sure magnet does not strike modules. Check

gap with a feeler gauge and readjust if necessary.

Final air gap: 0.280/0.330 mm (0.011/0.013 in.).

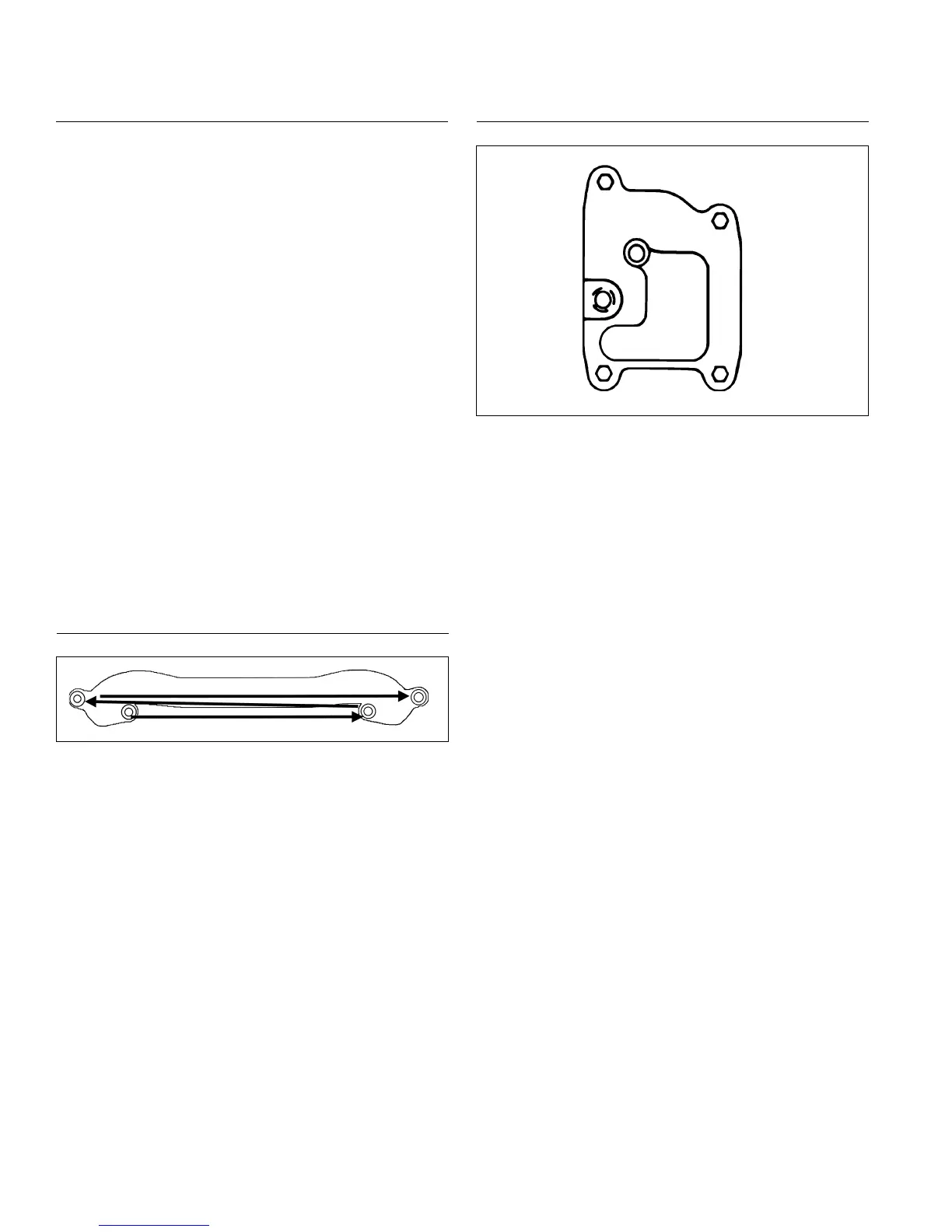

Install Intake Manifold

Torque Sequence

3

1 2

4

NOTE: If wires were disconnected from ignition modules

on engines with SMART-SPARK

™

, reattach

leads and seal base of terminal connectors with

GE/Novaguard G661 or equivalent dielectric

compound. Beads should overlap between

terminals to form a solid bridge of compound. Do

not put any compound inside terminals.

24 584 15-S ignition modules have a separator

barrier between terminals. On these modules,

seal base of terminals, but it is not necessary to

have overlapping beads of sealant between

connections.

1. Install intake manifold and new gaskets or O-rings

(plastic manifold), with wiring harness attached, to

cylinder heads. Slide any wiring harness clips onto

appropriate bolts before installing. Make sure

gaskets are in proper orientation. Using sequence

shown, torque screws in two increments, rst to

7.4 N·m (66 in. lb.), then to 9.9 N·m (88 in. lb.).

2. Connect kill lead to tab terminal on standard ignition

modules.

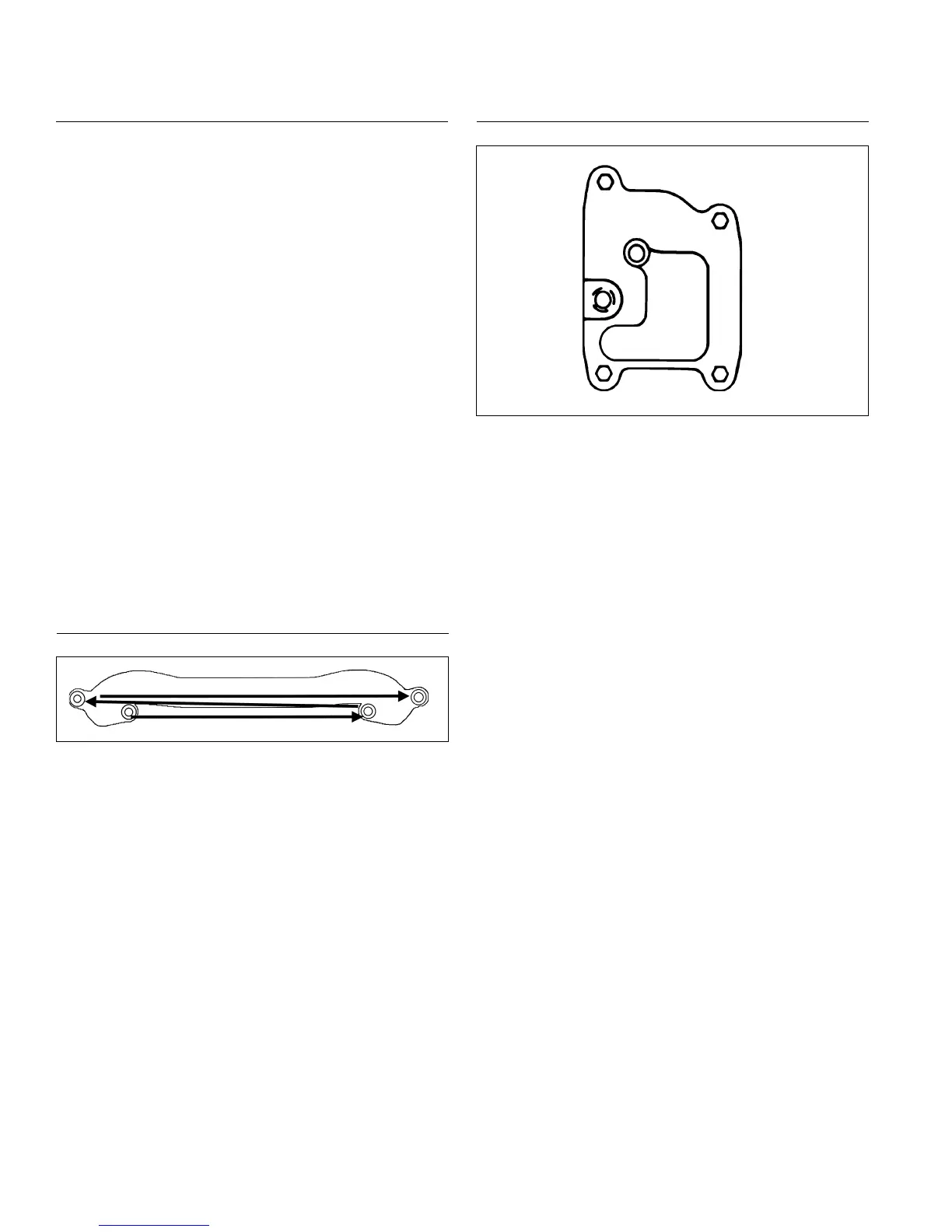

Install Breather Cover and Inner Bafes

Breather Cover Torque Sequence

1

2

3

4

RTV sealant was used on early models between

breather cover and crankcase. A gasket with imprinted

sealant beads is now used and recommended. Install as

follows.

1. Be sure sealing surfaces of crankcase and breather

cover are clean of old gasket material or RTV

sealant. Do not scrape surfaces as this could result

in leakage.

2. Check to make sure there are no nicks or burrs on

sealing surfaces.

3. Position breather gasket and cover on crankcase.

Install rst screws in locations 3 and 4 as shown.

Finger tighten at this time.

4. Install inner bafes using remaining screws and

nger tighten. Do not torque screws at this time; they

will be tightened after blower housing and outer

bafes are installed.

Reassembly

82

24 690 07 Rev. HKohlerEngines.com

Loading...

Loading...