10.2

Section 10

Reassembly

Cylinder #1

Cylinder #2

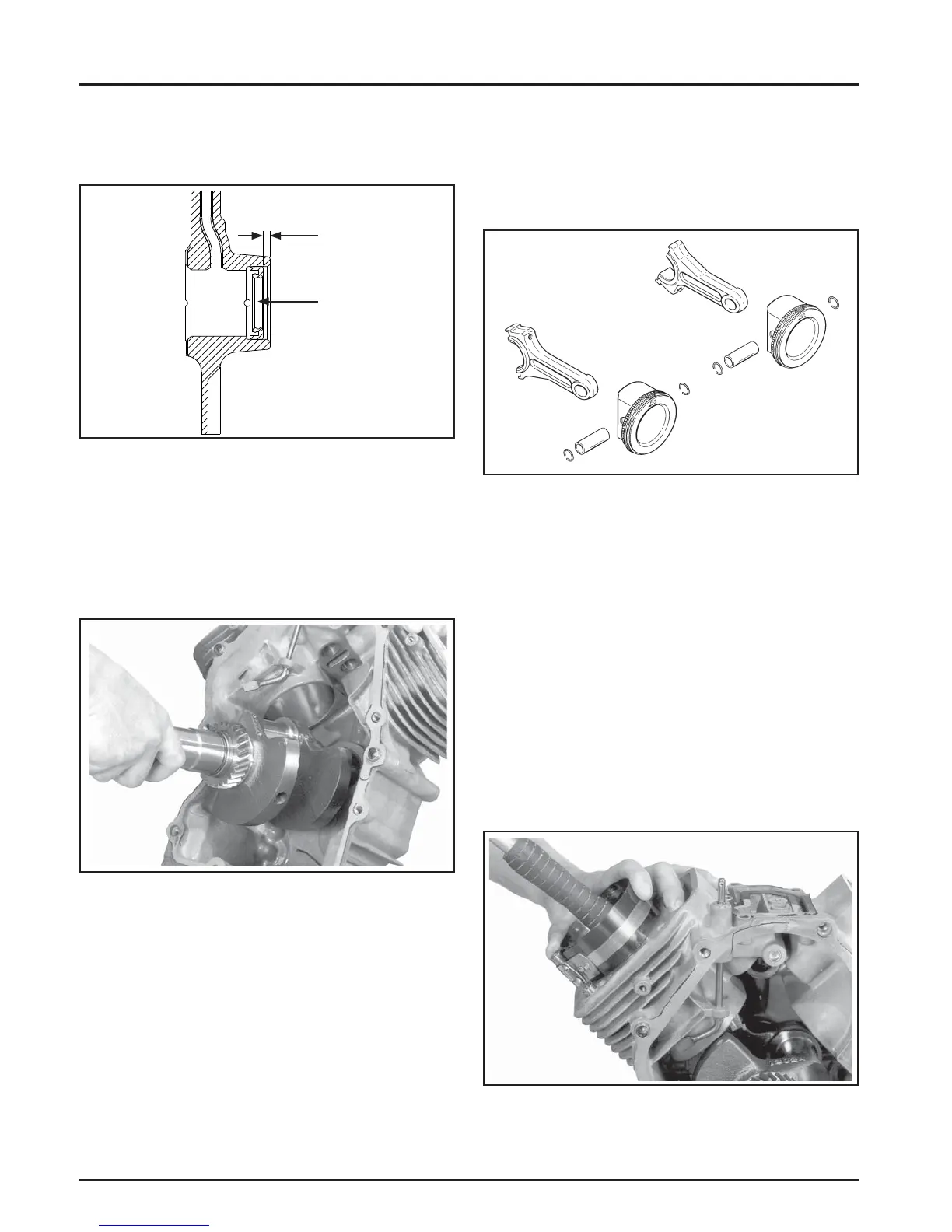

3. Drive the oil seal into the crankcase using a seal

driver. Make sure the oil seal is installed straight

and true in the bore to the depth shown in Figure

10-2.

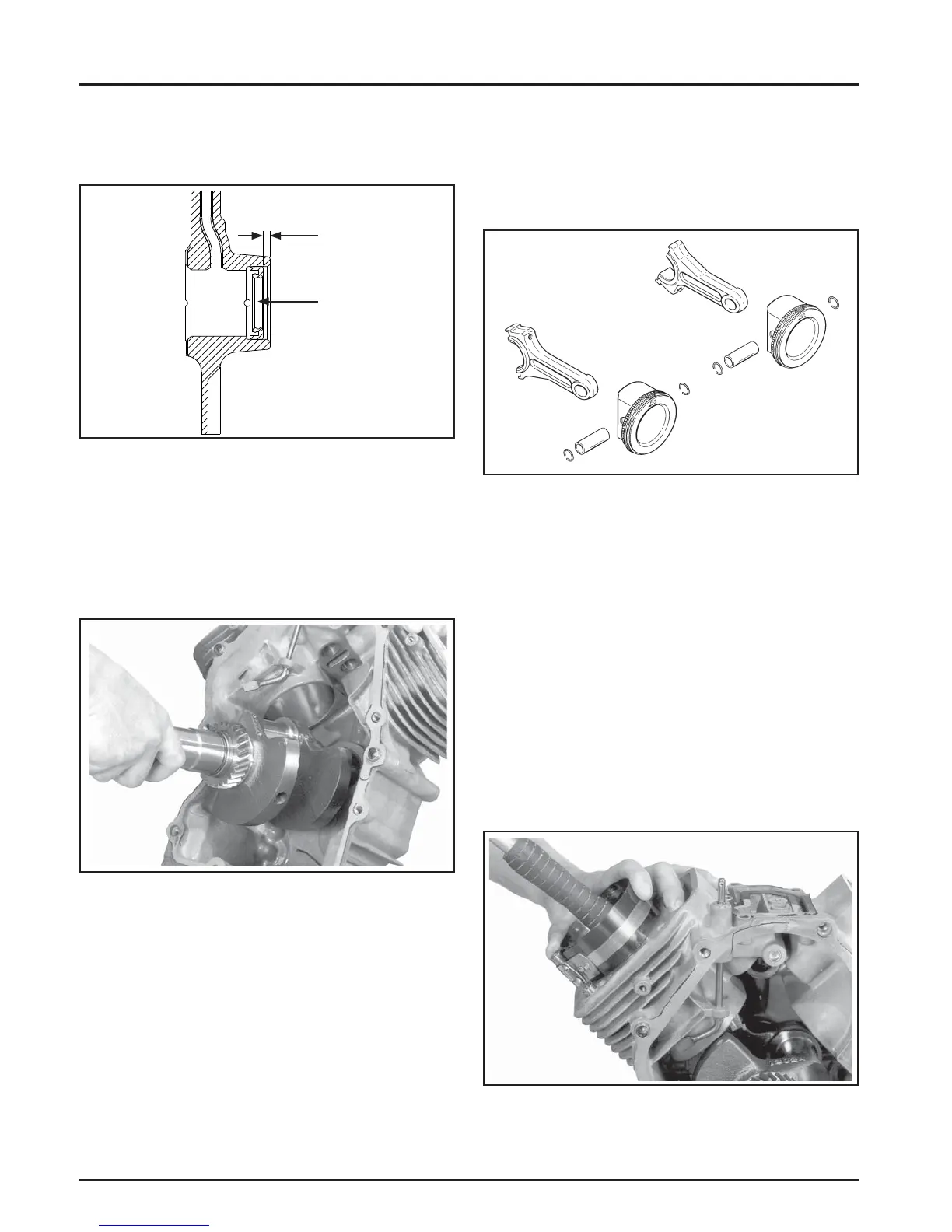

NOTE: Proper orientation of the piston/connecting

rod assemblies inside the engine is extremely

important. Improper orientation can cause

extensive wear or damage. Be certain the

pistons and connecting rods are assembled

exactly as shown in Figure 10-4.

Figure 10-3. Installing Crankshaft.

Install Connecting Rods with Pistons and

Rings

NOTE: The cylinders are numbered on the crankcase.

Make sure to install the piston, connecting

rod and end cap into its appropriate cylinder

bore as previously marked at disassembly.

Do not mix the end caps and connecting

rods.

Figure 10-5. Installing Piston Assembly Using Ring

Compressor Tool.

Figure 10-2. Installing Oil Seal.

Install Crankshaft

1. Lubricate the cranksha journals and connecting

rod bearing surfaces with engine oil.

2. Carefully slide the fl ywheel end of the cranksha

through the main bearing in the crankcase. See

Figure 10-3.

Figure 10-4. Piston, Connecting Rod, and Pin

Detail.

1. Stagger the piston rings in the grooves until the

end gaps are 120° apart. The oil ring rails should

also be staggered.

2. Lubricate the cylinder bore, piston, and piston

rings with engine oil. Compress the rings of the

#1 piston using a piston ring compressor.

3. Make sure the FLY stamping on the piston is

facing towards the fl ywheel side of the engine.

Use a hammer with a rubber grip and gently

tap the piston into the cylinder as shown in

Figure 10-5. Be careful that the oil ring rails do

not spring free between the bo om of the ring

compressor and top of the cylinder.

4.5 mm

(.177) in.

Oil Seal

Loading...

Loading...