10.4

Section 10

Reassembly

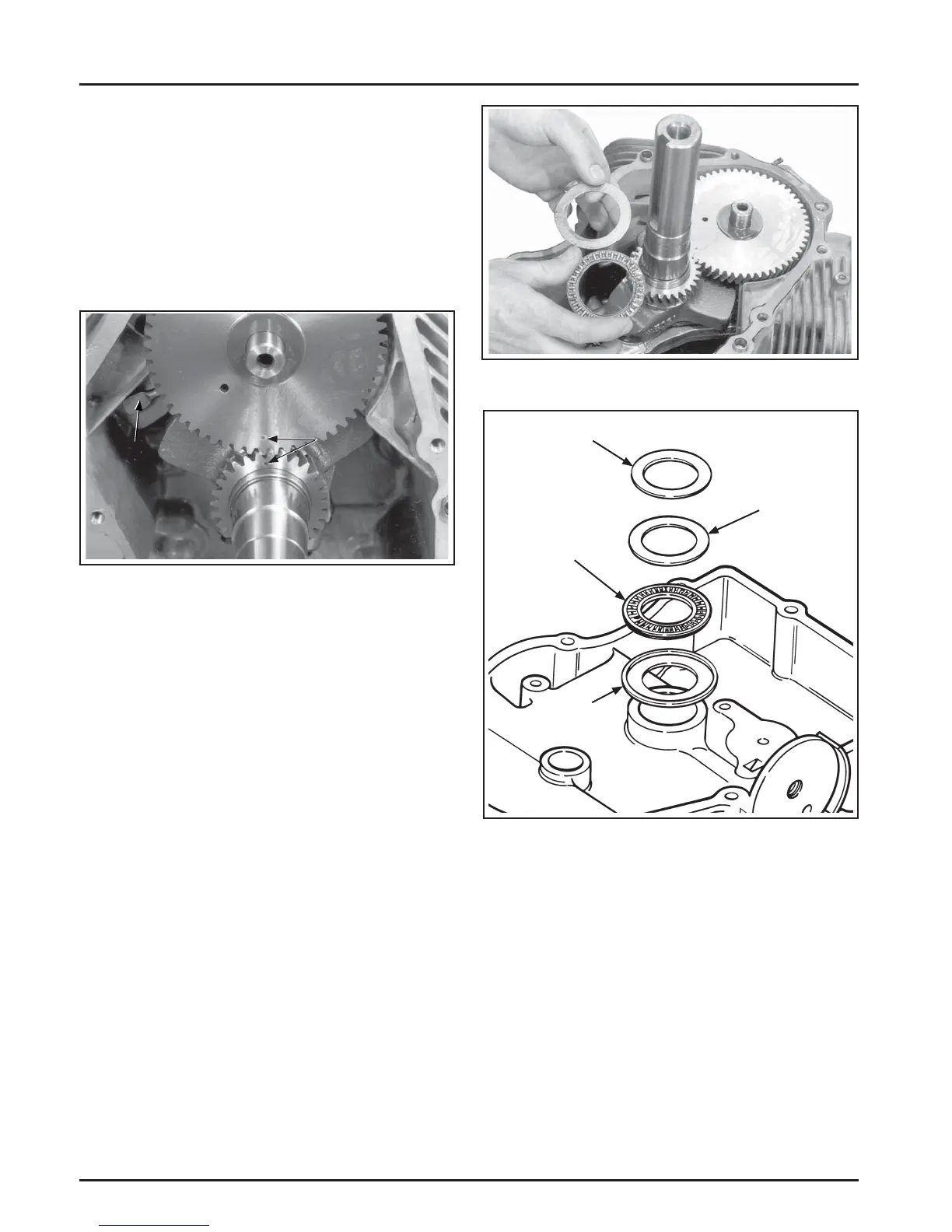

Figure 10-11. Thrust Bearing, Washer, and Shim

Used on Some Models.

Closure

Plate

Bearing

Race

Thrust Shim

Needle Thrust

Bearing

Thrust

Washer

Governor

Cross Shaft

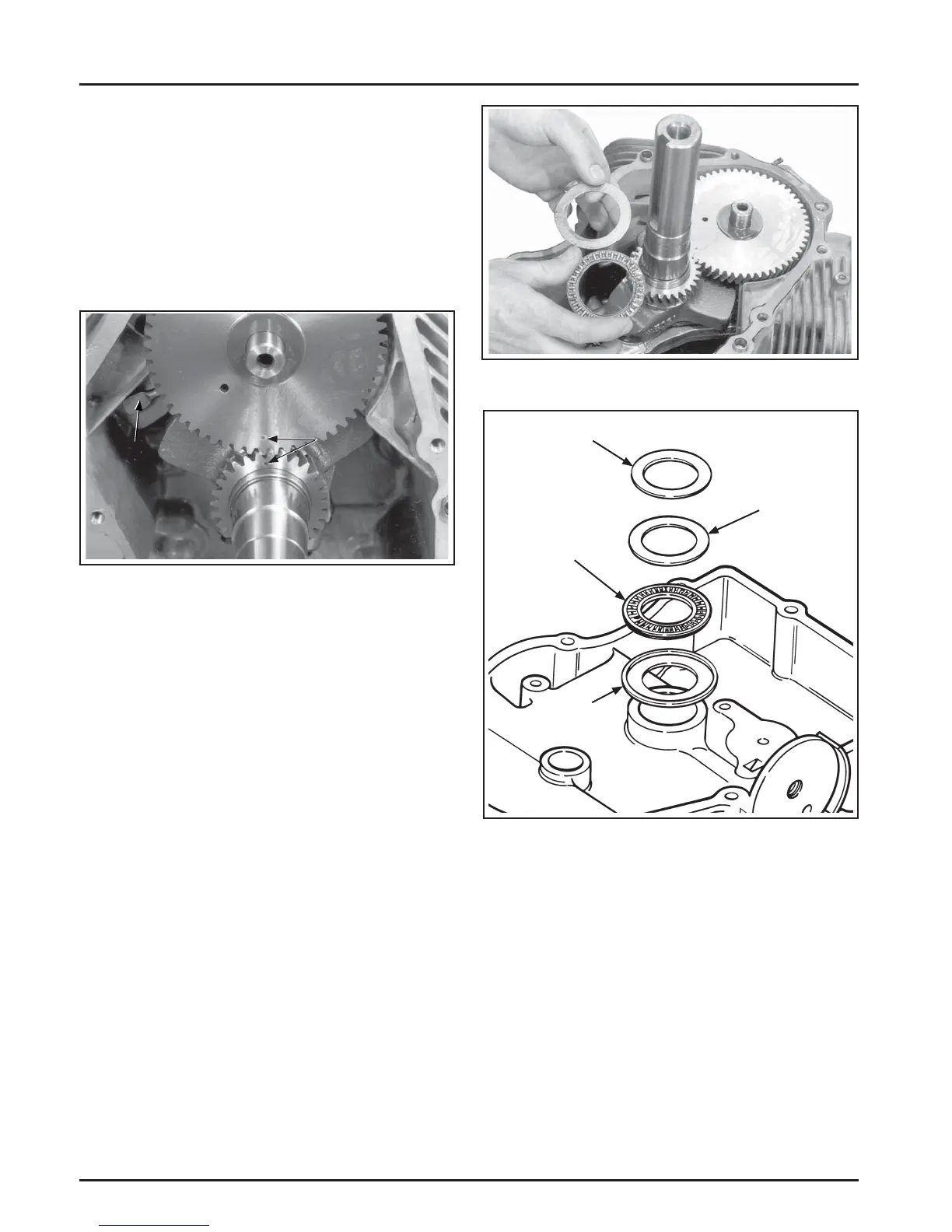

Timing

Marks

3. Turn the governor cross sha clockwise until the

lower end of the sha contacts the cylinder. Make

sure the cross sha remains in this position while

installing the camsha . See Figure 10-10.

4. Slide the camsha into the bearing surface of the

crankcase, positioning the timing mark of the

camsha gear at the 6 o’clock position. Make sure

that the camsha gear and cranksha gear mesh,

with both timing marks aligned. See Figure 10-10.

Figure 10-10. Aligning Crankshaft and Camshaft

Timing Marks.

Oil Pump Assembly

The oil pump is mounted inside the closure plate. If

service was required, and the oil pump was removed,

refer to the assembly procedures under Oil Pump

Assembly in Section 9.

Governor Gear Assembly

The governor gear assembly is located inside the

closure plate. If service was required, and the

governor was removed, refer to the assembly

procedures under Governor Gear Assembly in

Section 9.

Thrust Bearing, Washer and Shim

Some specifi cations use a needle type thrust bearing,

thrust washer and shim spacer to control the end

play of the cranksha . See Figure 10-11. If these items

are noted during disassembly, make sure they are

reinstalled in the sequence shown in Figure 10-12. A

diff erent procedure will have to be followed to check

and adjust cranksha end play on these models.

Figure 10-12. Correct Sequence of Thrust Bearing,

Washer, and Shim in Closure Plate.

The race for the thrust bearing presses loosely into

the closure plate. If it is not already installed, push it

into the cranksha bore inside the closure plate. Pack

the thrust bearing with heavy grease and stick the

bearing into the race. Wipe some grease on the face of

the thrust washer and stick it onto the thrust bearing.

Wipe some grease on the face of the original shim

spacer and stick it onto the thrust washer.

Install the closure plate onto the crankcase without

applying RTV sealant and secure it with only two or

three of the fasteners at this time. Use a dial indicator

to check the cranksha end play. End play should

be 0.070/0.270 mm (0.0028/0.0100 in.). Shim spacers

are available in the three color coded thicknesses if

adjustment is needed.

Loading...

Loading...