7.6

Section 7

Electrical System and Components

Troubleshooting Guide

20/25 Amp Battery Charging Systems

When problems occur in keeping the ba ery charged or the ba ery charges at too high a rate, the problem can

usually be found somewhere in the charging system or with the ba ery.

NOTE: Always zero ohmmeter on each scale before testing to ensure accurate readings. Voltage tests should

be made with the engine running at 3600 RPM - no load. The ba ery must be good and fully charged.

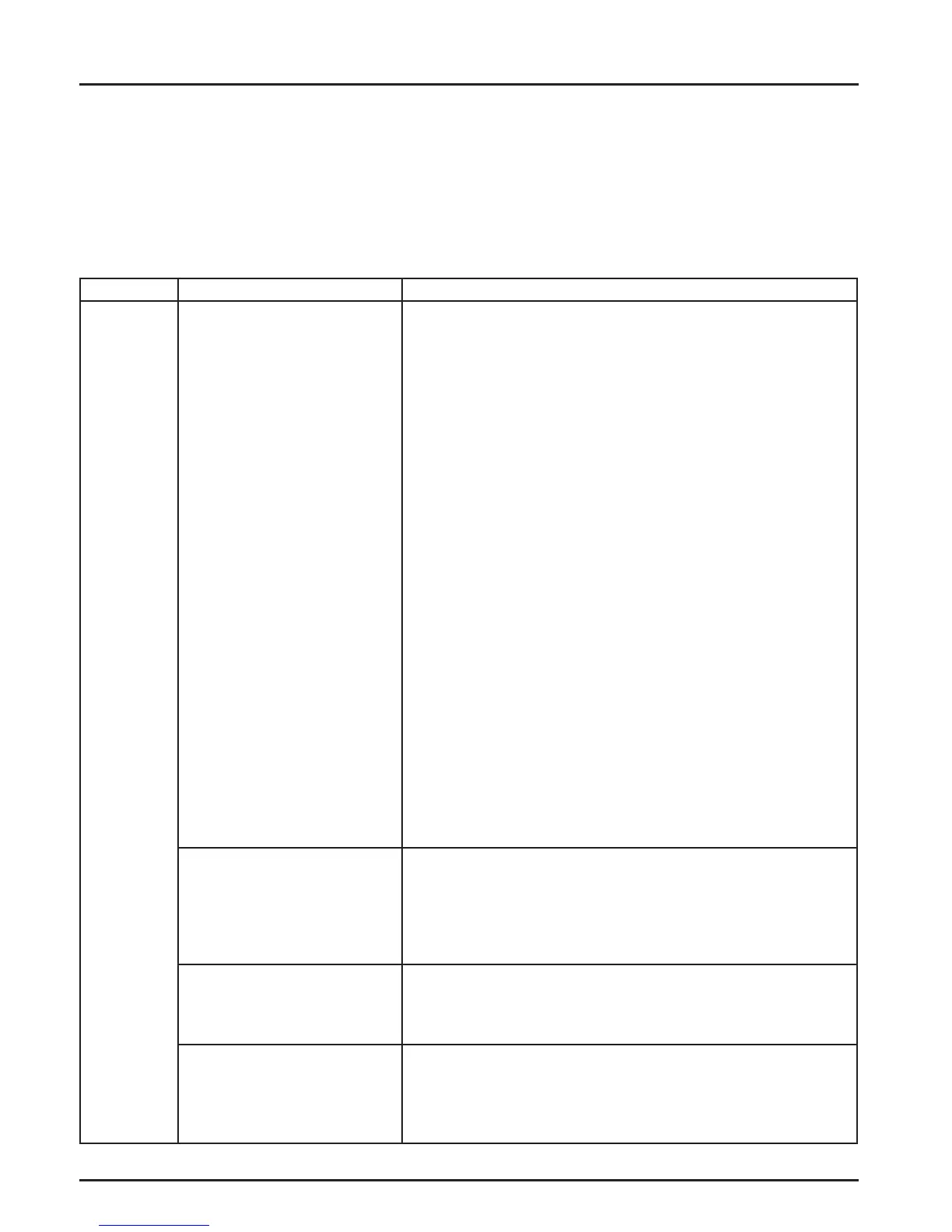

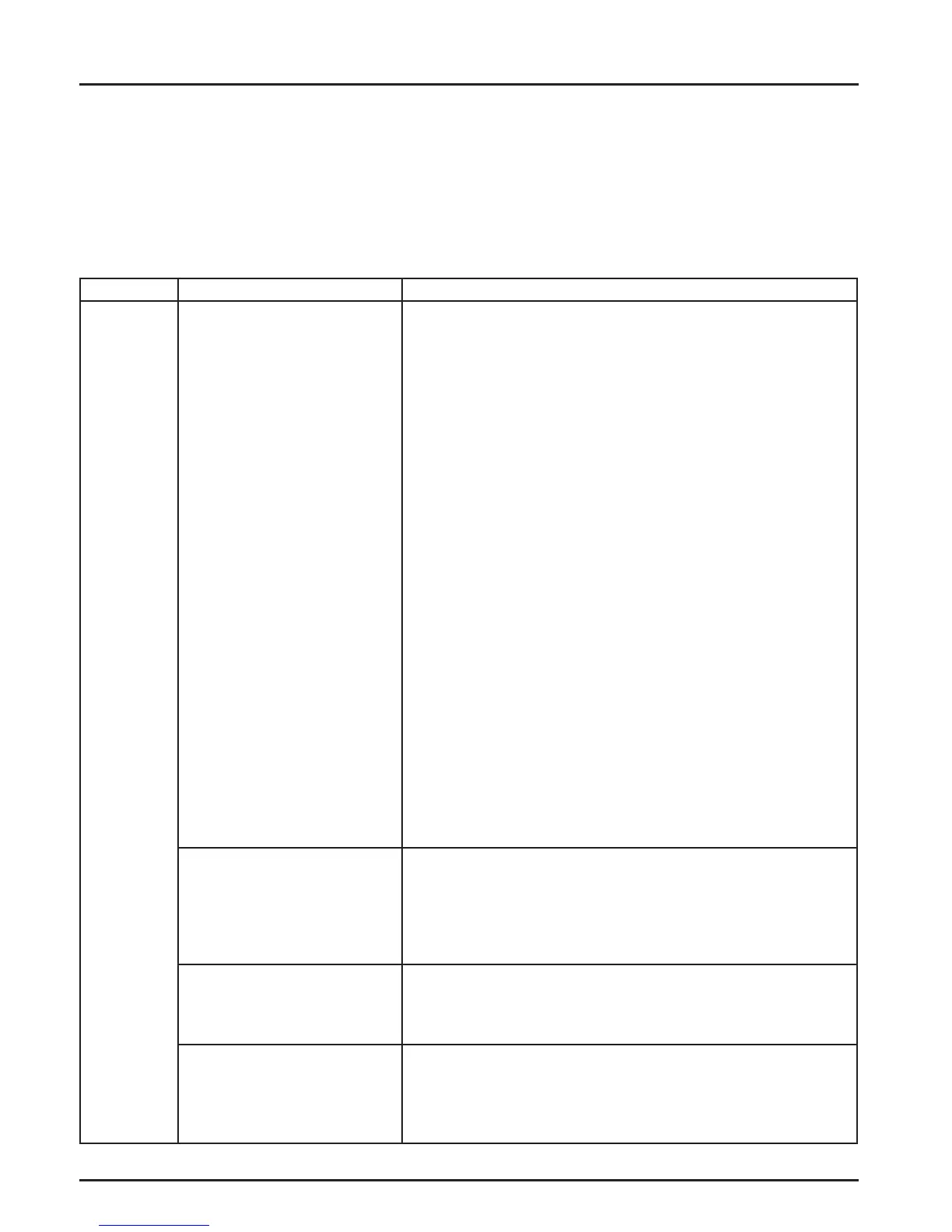

Problem Test Conclusion

No Charge

to Battery

1. Trace B+ lead from

rectifi er-regulator to key

switch, or other accessible

connection. Disconnect it

from switch or connection.

Connect an ammeter from

loose end of B+ lead to

positive terminal of ba ery.

Connect DC voltmeter

from loose end of B+

lead to negative terminal

of ba ery. With engine

running at 3600 RPM, read

voltage on voltmeter.

If voltage is 13.8 volts or

more, place a minimum

load of 5 amps* on ba ery

to reduce voltage. Observe

ammeter.

*NOTE: Turn on lights, if 60

wa s or more. Or place

a 2.5 ohm, 100 wa

resistor across ba ery

terminals.

1. If voltage is 13.7-14.7 and charge rate increases when load

is applied, the charging system is OK and ba ery was fully

charged.

If voltage is less than 13.8 or charge rate does not increase

when load is applied, test rectifi er-regulator for proper

ground. Using an ohmmeter set to the Rx1 scale, check

the resistance from the rectifi er-regulator housing to the

ba ery ground. Resistance should be less than 1 ohm. As an

alternative, connect a jumper lead from rectifi er-regulator

housing to the ba ery ground and retest charging voltage. If

charge voltage measures 13.7-14.7 volts, the charging system

is functioning. If resistance is greater than 1 ohm or charge

voltage is less than 13.7, then re-establish ground between

the ground strap and mounting screw.

If voltage is less than 13.8 or charge rate does not increase

when load is applied, test stator (Tests 2 and 3).

If the voltage is low and does not increase, and there is no

charging/amperage output, disconnect and reconnect the

rectifi er-regulator plug and retest.

a. If the ammeter shows charge for a short time but then

drops back to zero, the rectifi er-regulator is functioning

correctly but the ba ery is faulty. Replace the ba ery.

b. If no amperage/charge rate appears during the retest, go

to step 2.

2. Remove connector from

rectifi er-regulator. With

engine running at 3600

RPM, measure AC voltage

across stator leads using an

AC voltmeter.

2. If voltage is 28 volts or more, stator is OK. Rectifi er-regulator

is faulty. Replace the rectifi er-regulator.

If voltage is less than 28 volts, stator is probably faulty and

should be replaced. Test stator further using an ohmmeter

(Test 3).

3a. With engine stopped,

measure the resistance

across stator leads using an

ohmmeter.

3a. If resistance is 0.064/0.2 ohms, the stator is OK.

If the resistance is infi nity ohms, stator is open. Replace

stator.

3b. With the engine stopped,

measure the resistance

from each stator lead

to ground using an

ohmmeter.

3b. If the resistance is infi nity ohms (no continuity), the stator is

OK (not shorted to ground).

If resistance (or continuity) is measured, the stator leads are

shorted to ground. Replace stator.

Loading...

Loading...