9.2

Section 9

Inspection and Reconditioning

Procedure to Install New Plug:

1. Use a single cylinder camsha pin Part No.

47 380 09-S as a driver and tap the plug into the

plug bore until it seats at the bo om of the bore.

Make sure the plug is tapped in evenly to prevent

leakage.

Crankcase

Inspection and Service

Check all gasket surfaces to make sure they are free of

gasket fragments. Gasket surfaces must also be free of

deep scratches or nicks.

Check the cylinder bore for scoring. In severe cases,

unburned fuel can cause scuffi ng and scoring of the

cylinder wall. It washes the necessary lubricating

oils off the piston and cylinder wall. As raw fuel

seeps down the cylinder wall, the piston rings make

metal to metal contact with the wall. Scoring of the

cylinder wall can also be caused by localized hot

spots resulting from blocked cooling fi ns or from

inadequate or contaminated lubrication.

If the cylinder bore is badly scored, excessively worn,

tapered, or out-of-round, resizing is necessary. Use

an inside micrometer to determine the amount of

wear (refer to Specifi cations, Tolerances, and Special

Torque Values in Section 1), then select the nearest

suitable oversize of either 0.25 mm (0.010 in.) or

0.50 mm (0.020 in.). Resizing to one of these oversizes

will allow usage of the available oversize piston and

ring assemblies. First, resize using a boring bar, then

use the following procedures for honing the cylinder.

Honing

While most commercially available cylinder hones

can be used with either portable drills or drill presses,

the use of a low speed drill press is preferred as it

facilitates more accurate alignment of the bore in

relation to the cranksha crossbore. Honing is best

accomplished at a drill speed of about 250 RPM and

60 strokes per minute. A er installing coarse stones in

hone, proceed as follows:

1. Lower hone into bore and a er centering, adjust

so that the stones are in contact with the cylinder

wall. Use of a commercial cu ing-cooling agent is

recommended.

2. With the lower edge of each stone positioned

even with the lowest edge of the bore, start drill

and honing process. Move the hone up and down

while resizing to prevent the formation of cu ing

ridges. Check the size frequently.

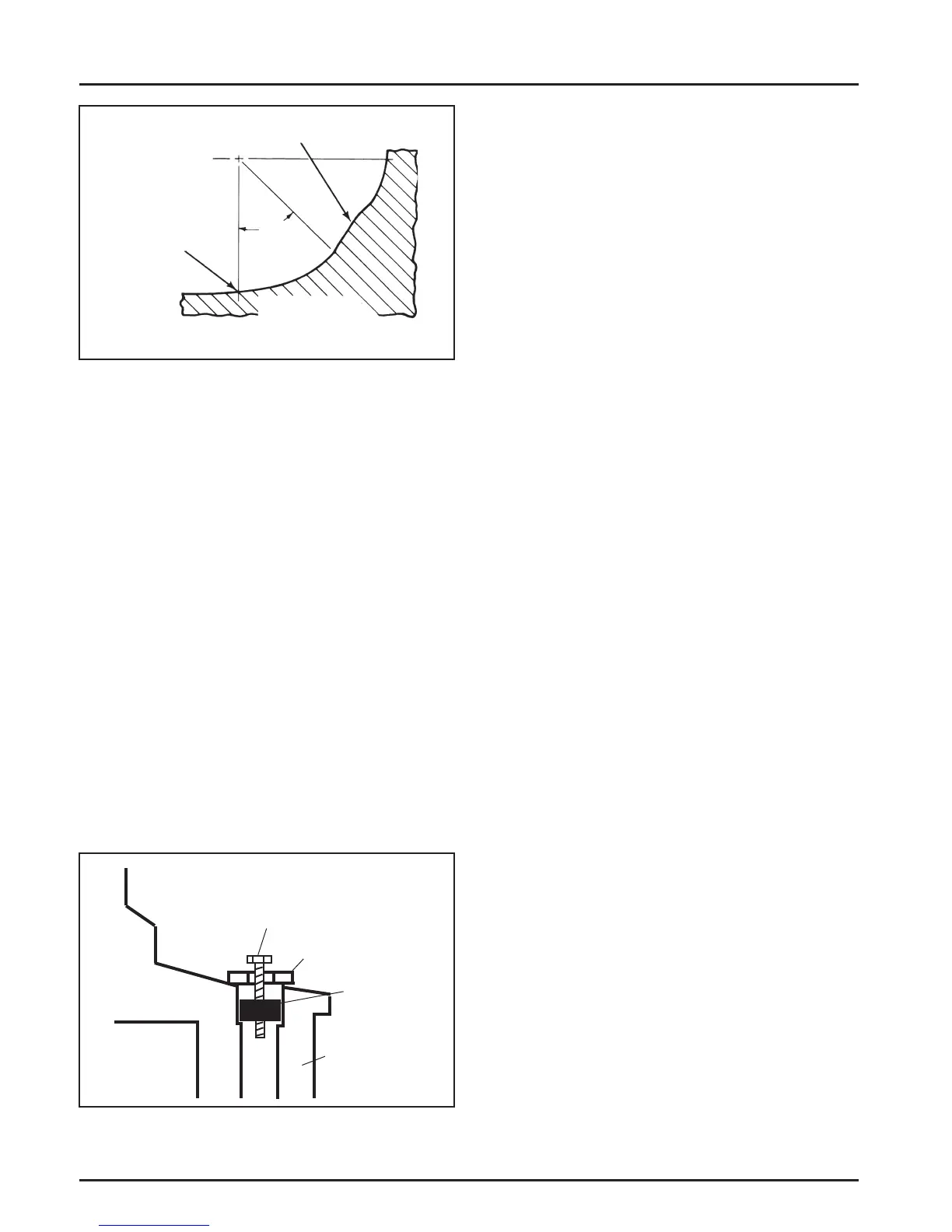

Figure 9-1. Crankpin Fillets.

The connecting rod journal can be ground one size

under. When grinding the cranksha , grinding stone

deposits can get caught in the oil passages, which

could cause severe engine damage. Removing the

crankpin plug when the cranksha is ground provides

easy access for removing any grinding deposits that

may collect in the oil passages.

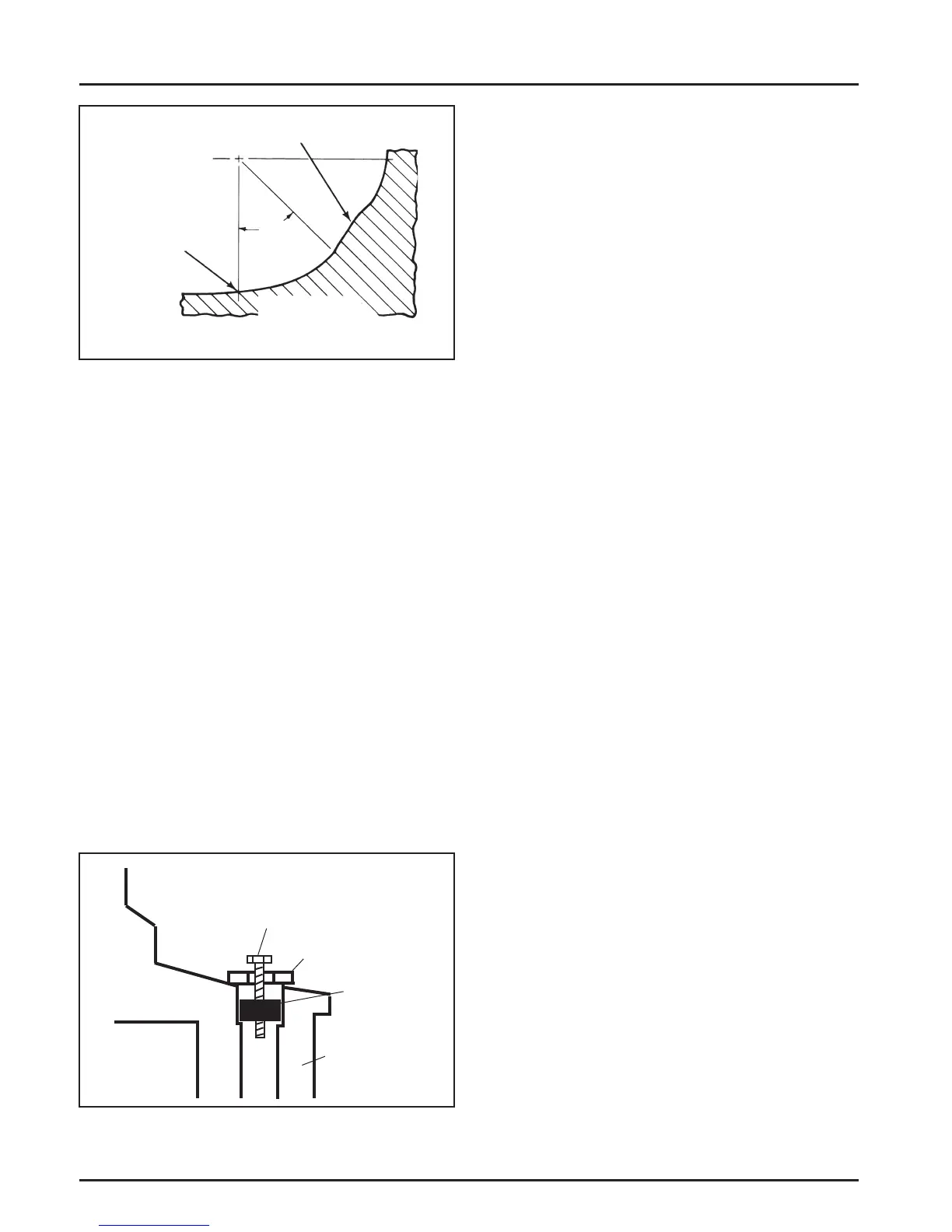

Use the following procedure to remove and replace

the plug.

Procedure to Remove Crankshaft Plug:

1. Drill a 3/16 in. hole through the plug in the

cranksha .

2. Thread a 3/4 in. or 1 in. long self-tapping screw

with a fl at washer into the drilled hole. The fl at

washer must be large enough to seat against the

shoulder of the plug bore. See Figure 9-2.

3. Tighten the self-tapping screw until it draws the

plug out of the cranksha .

Figure 9-2. Removing Crankpin Plug.

45°

High Point from

Fillet Intersections

This Fillet Area

Must Be Completely

Smooth

Minimum

The Fillet Must

Blend Smoothly

with the Bearing

Journal Surface

Flat Washer

Self-Tapping Screw

Plug

Crankshaft

Loading...

Loading...