10.5

Section 10

Reassembly

10

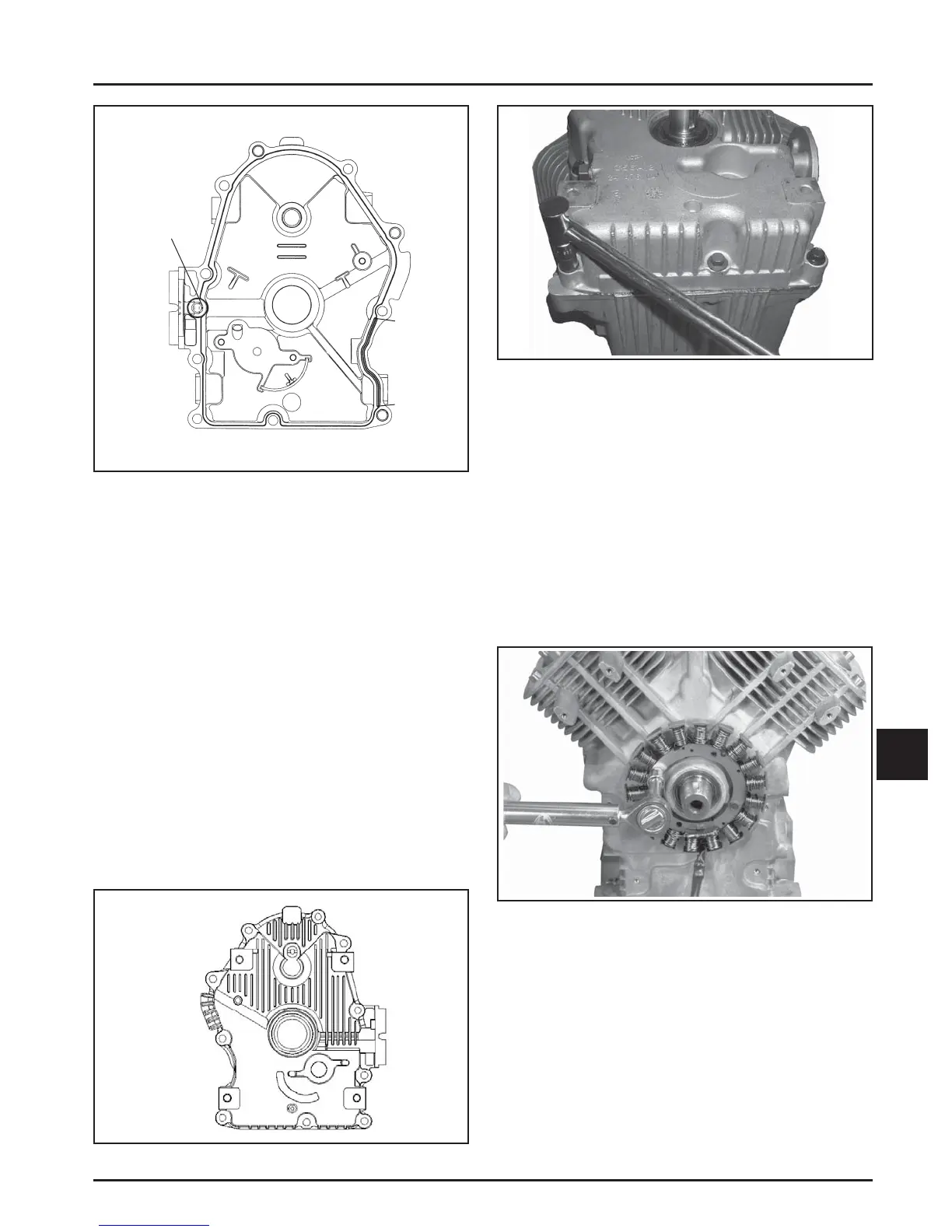

Figure 10-13. Oil Pan Sealant Pattern.

4. Make sure the end of the governor cross sha is

lying against the bo om of cylinder 1 inside the

crankcase. See Figure 10-10.

5. Install the oil pan to the crankcase. Carefully seat

the camsha and the cranksha into their mating

bearings. Rotate the cranksha slightly to help

engage the oil pump and governor gear meshes.

6. Install the ten hex fl ange screws securing the oil

pan to the crankcase. Torque the fasteners in the

sequence shown in Figure 10-14 to 25.6 N·m

(227 in. lb.). One of the ten mounting screws has

a thread sealant patch. This screw is typically

installed in the number 10 hole shown in Figure

10-14. Reapply pipe sealant with Tefl on

®

(Loctite

®

592

™

PST

®

Thread Sealant or equivalent) to the

number 10 oil pan screw as required. See Figure

10-15.

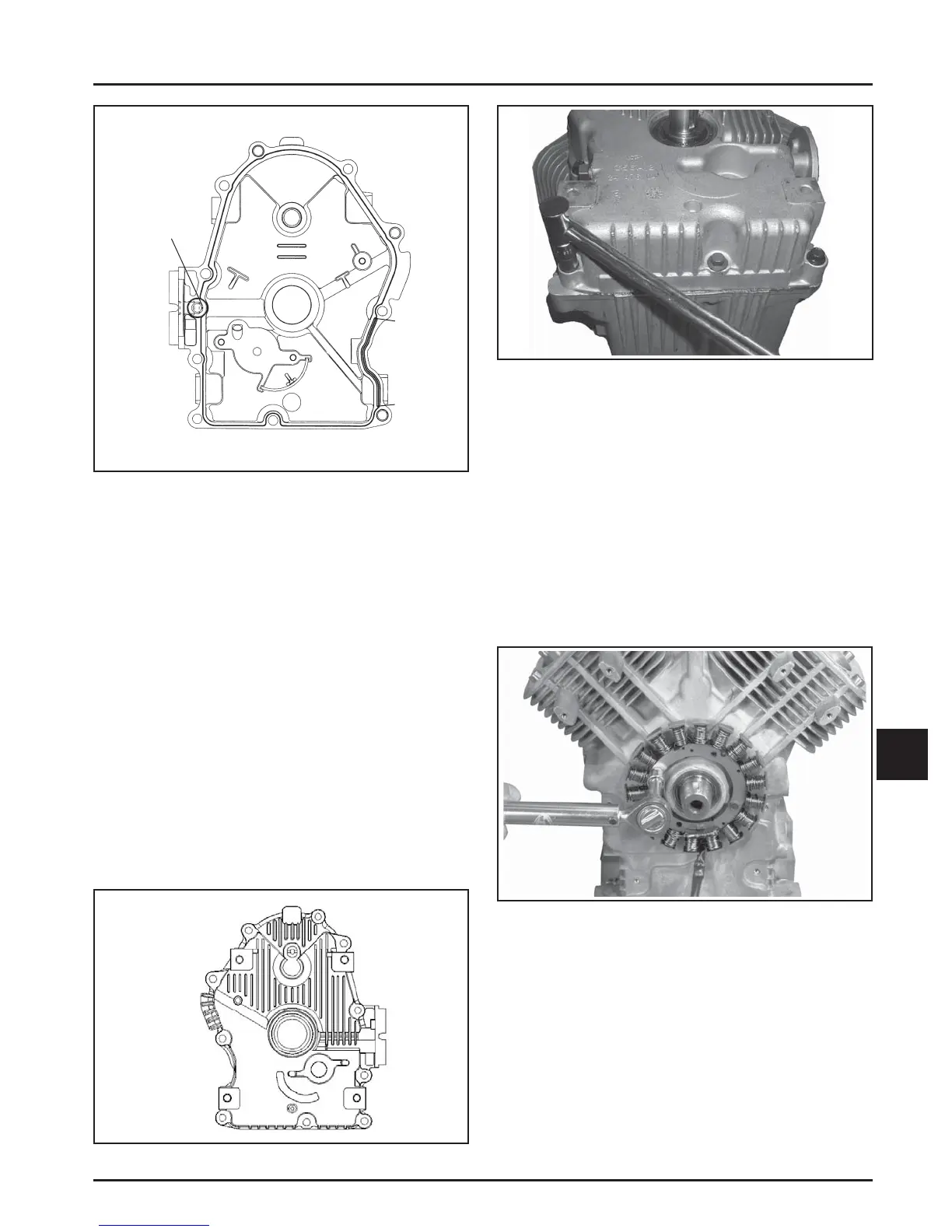

Figure 10-15. Torquing Oil Pan Fasteners.

Install Stator and Backing Plate

1. Apply pipe sealant with Tefl on

®

(Loctite

®

592

™

PST

®

Thread Sealant or equivalent) to the stator

mounting holes.

2. Position the stator aligning the mounting holes so

that the leads are at the bo om, towards the

crankcase.

3. Install and torque the two hex fl ange screws to

6.2 N·m (55 in. lb.) for new holes or 4.0 N·m

(35 in. lb.) for used holes. See Figure 10-16.

Apply 1.5 mm (1/16 in.)

bead of sealant.

RTV must be

all around

O-ring

groove

Point B

Fill groove between points A and B with RTV.

Point A

1

10

8

6

4

2

9

7

5

3

Figure 10-16. Torquing Stator Screws.

4. Route the stator leads in the crankcase channel,

then install the backing plate. Secure with the

four hex fl ange screws. See Figures 10-17 and

10-18. Torque the screws 10.7 N·m (95 in. lb.) for

new holes or 7.3 N·m (65 in. lb.) for used holes.

Figure 10-14. Oil Pan Fastener Torque Sequence.

Loading...

Loading...