SERVICE PROCEDURE MAINTENANCE

4-26

WHEN LOOSENING TENSION

WARNING

It is extremely dangerous to release the grease by any method except the procedure given below. If the

track tension is not relieved by this procedure, please contact your Komatsu distributor.

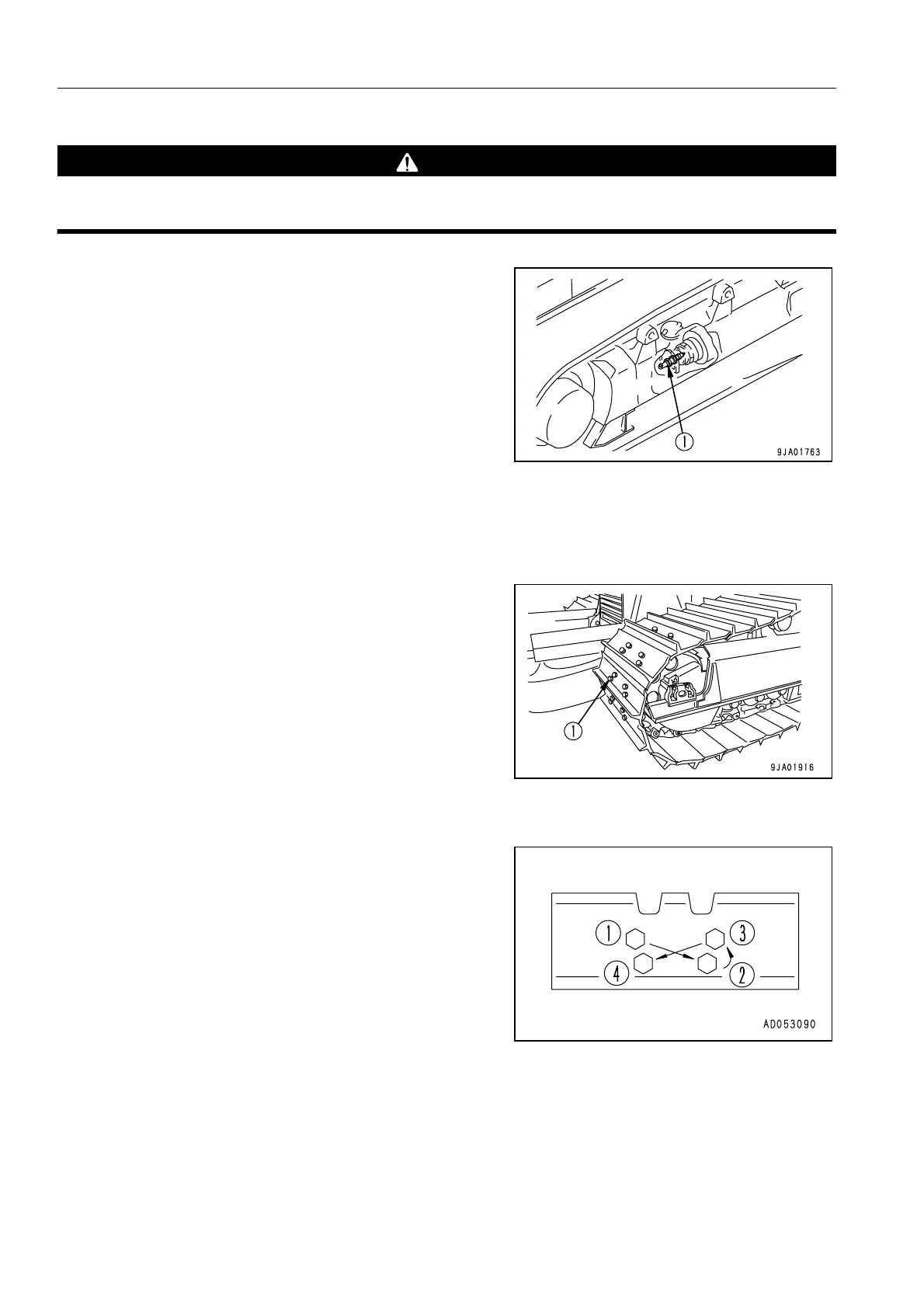

1. Loosen lubricator(1) gradually to release the grease.

2. Turn lubricator(1) a maximum of one turn.

3. If the grease does not come out smoothly, move the

machine backwards and forwards a short distance.

4. Tighten lubricator(1).

5. To check that the correct tension has been achieved,

move the machine backwards and forwards.

6. Check the track tension again, and if the tension is not

correct, adjust it again.

CHECK AND TIGHTEN TRACK SHOE BOLTS

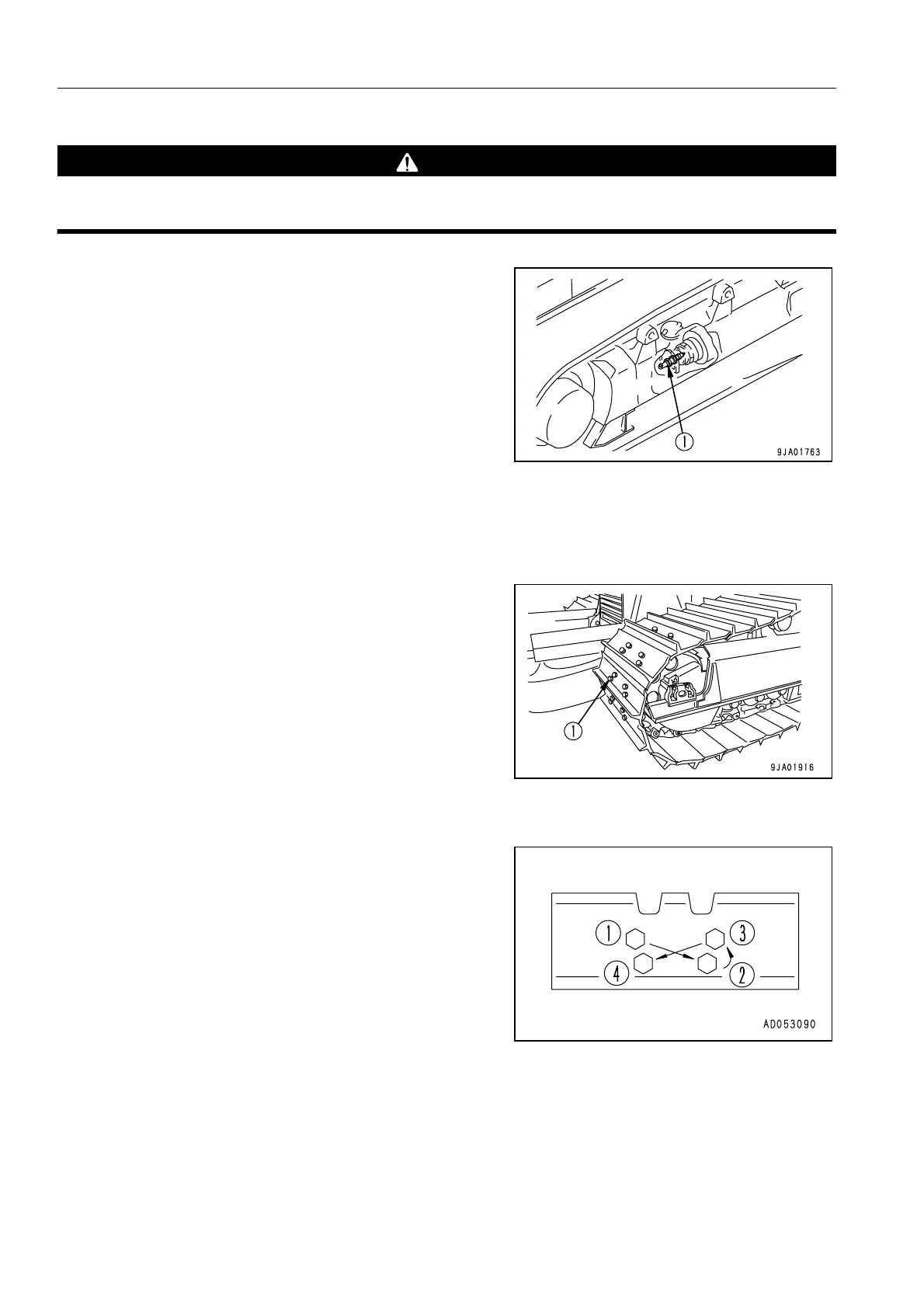

If the machine is used with track shoe bolts(1) loose, they will

break, so tighten any loose bolts immediately.

ORDER FOR TIGHTENING

Tighten the bolts in the order shown in the diagram on the right.

METHOD FOR TIGHTENING (SHOE BOLT)

1. First tighten to a tightening torque of 392 ± 39.2N•m(40 ± 4kgf•m, 290 ± 30lbft) then check that the nut and

shoe are in close contact with the link contact surface.

2. After checking, tighten a further 120 º ± 10º.

Loading...

Loading...